Excellent surface quality, high productivity

SMS group ranks among the leading suppliers of plant technology and equipment for the production of high-quality stainless steel strip. Our portfolio of cold rolling mills for stainless steel comprises stand-alone 20-high mills in MonoBlock and SplitBlock-design as well as our 18-HS stands which are also suited for integration and use in continuous mills.

Single-stand 20-high mills have been part of SMS group’s product range for decades. Depending on the application, 20-high mills come in different sizes and in two versions: the closed, robust MonoBlock or the more flexible SplitBlock type. They can fulfill any material and surface requirement. Apart from the main application stainless steel, they can also be used for the production of silicon steel, copper and copper alloys as well as for titanium strips.

For higher production capacities, SMS group has developed the 18-HS (horizontal stabilization) mill design. In this 18-roll stand, the very thin rolls are supported against lateral buckling. With the 18-HS mill design, high-strength and stainless steel grades can be produced more efficiently. Integrated in a continuous tandem cold mill, our 18-HS allows you to set up a full, continuous production route for stainless steel. By using rolling oil, this type of plant produces surface finishes that match cold rolled strip produced in 20-high mills. The 18-HS design is also available in combination with CVC® plus, a technology package for strip profile, contour and flatness control.

Specifically, in a five-stand tandem cold mill (TCM) in 18-HS design, reductions of up to 70 percent are possible. Even a second run of hard material is no problem

-

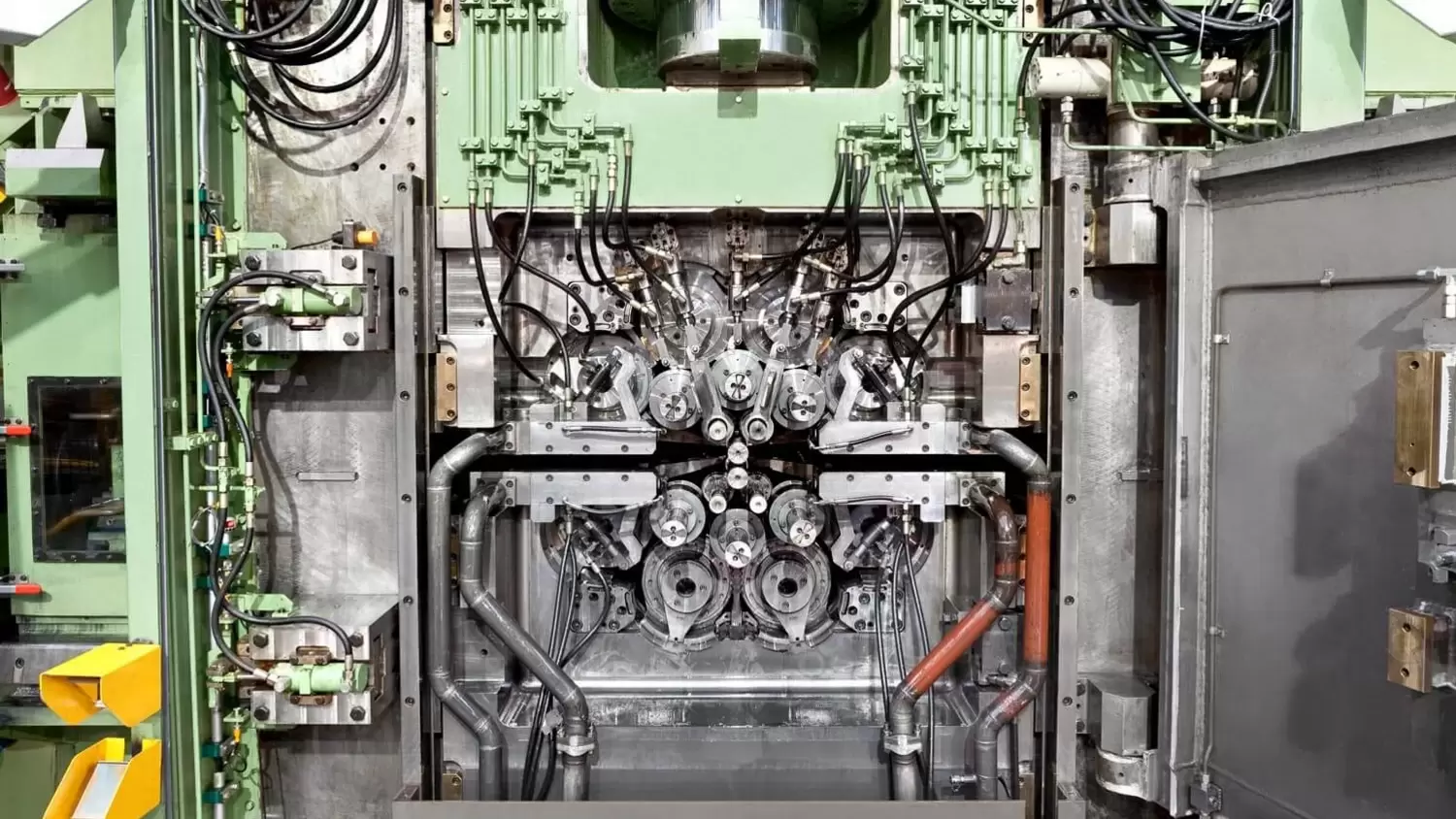

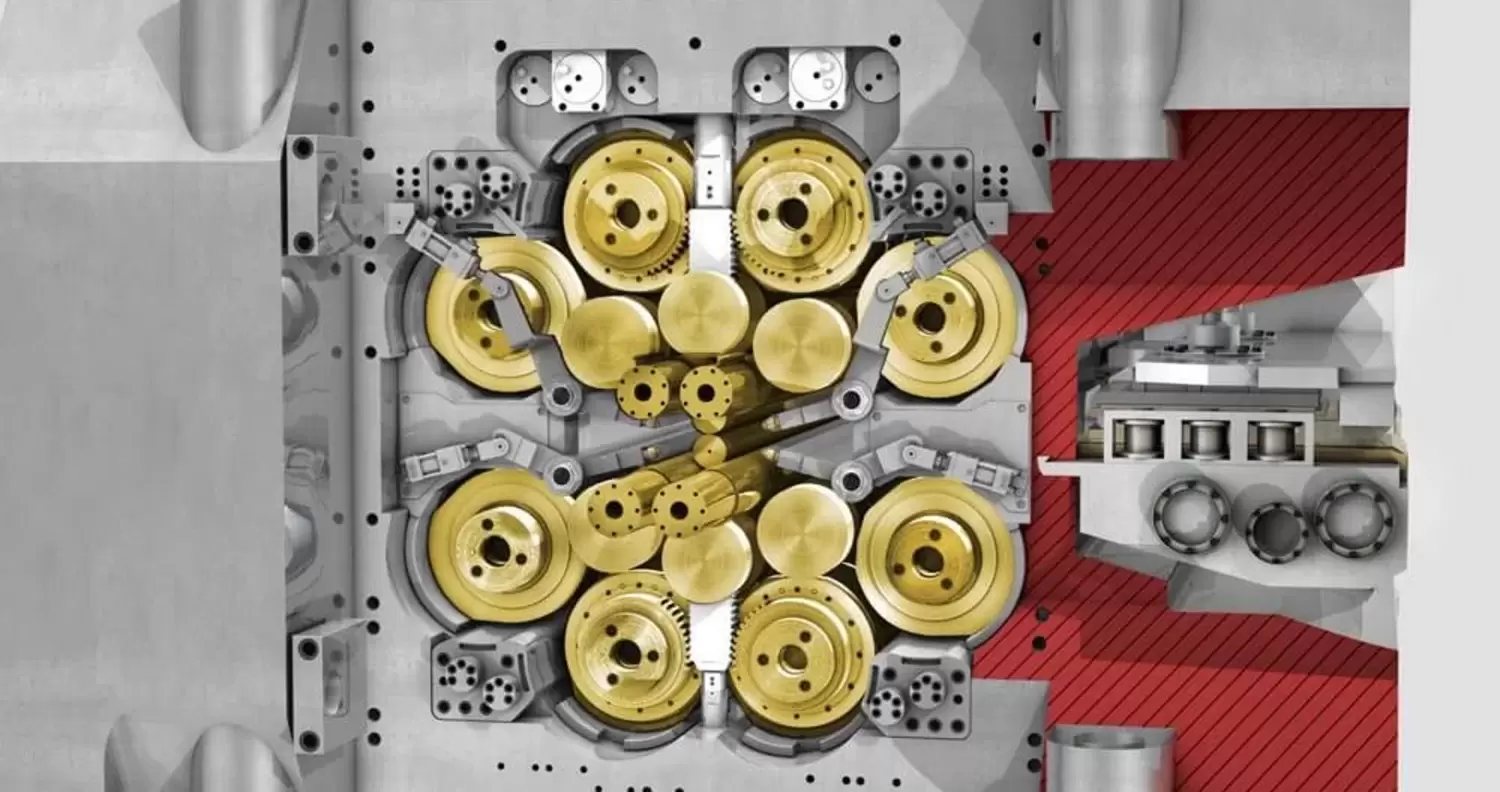

20-high mill: MonoBlock design

Best in its class for extremely hard material grades

Main dataCompact and robust, this stand comes with superb rigidity. That makes it ideal for rolling even the hardest material grades, e.g. AISI 200 and 300 stainless steel. You can expect reductions of up to 90 percent.

Furthermore, precisely coordinated mechatronic systems with highly developed actuators, together with control systems for thickness and flatness and via filter systems, ensure efficient production and outstanding strip quality.The MonoBlock is the core component of the single-stand reversing cold mill. We manufacture these mills in modular design.

![]()

20-high mill: MonoBlock design -

20-high mill: SplitBlock design

Proven effective for challenging final products

Main dataSplitBlock stands from SMS group are capable of rolling a large product mix of material grades and thicknesses. Split into an upper and a lower half, the stand opens wider to accommodate larger-diameter work rolls. This design provides easy access during roll changing. It also simplifies the threading procedure.

There are various actuators or control elements for roll-gap setting that ensure the SplitBlock stand can process the whole range of strip qualities. Also featured is a thickness and flatness control system. All rolling parameters are preset by SMS group on the basis of a mathematical model and controlled fully automatically during the rolling process. The mill is manufactured in modular design.

![]()

20-high mill: SplitBlock design -

18-HS design: Reversing cold mill (RCM)

Flexible production

Main dataBoth as a roughing stand for the thickness reduction of hot-rolled black coils and for the precise finish rolling of cold strip (white coil), this stand concept from the SMS group offers the ideal solution. Key components of 18-HS roll sets for RCMs are slim laterally supported work rolls. They come in diameters of between 120 and 160 millimeters, depending on the mill stand size. What they have in common is that they are all capable of high reductions. With this mill type even AISI 200, 300 and 400-grade unpickled material can be rolled into high-quality finished strip.

All 18-HS mills can come with our CVC® plus technology. Using the special CVC® plus roll contour means you can correct more severe flatness defects over a wider range than with other approaches. You also benefit from easy, fast work-roll and intermediate-roll changing.

![]()

Reversing cold mill in 18-HS design -

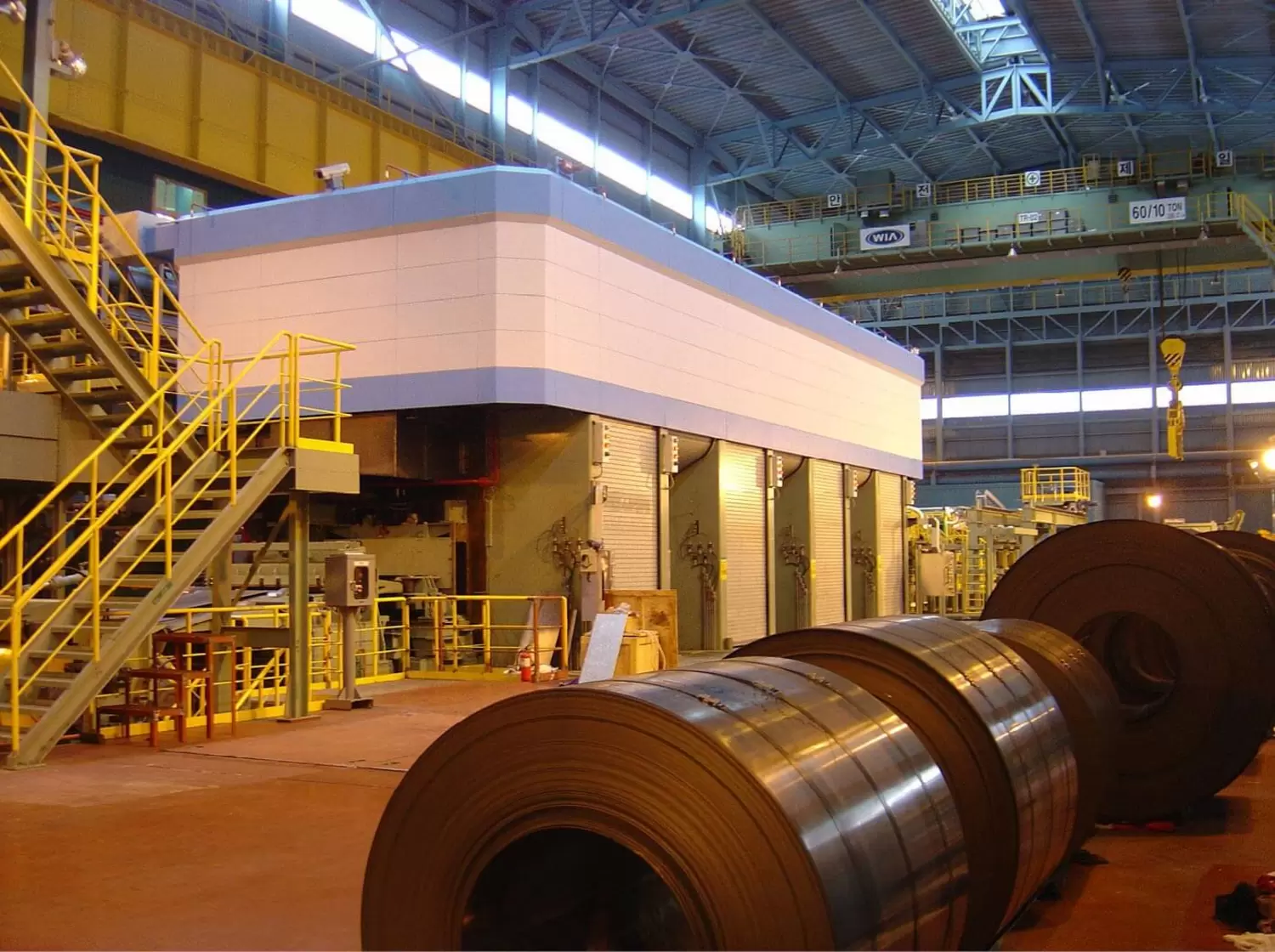

18-HS design: Continuous tandem cold mill (CTCM)

For production capacities of up to 1 million tons

Main dataA tailor-made plant concept that is second to none... economical production of high-quality cold-rolled strip on a continuous 18-HS tandem rolling mill. It is the most cost-effective option, if you aim for an annual capacity of more than 400,000 tons. Compared with using individual reversing mills for large production volumes, a tandem mill means lower investment and operating costs.

First in line here is the continuous entry section. It includes these machines: double pay-off reel, crop shear for the strip head end, welder, strip accumulator, and strip cleaning section. Downstream of that, the tandem mill consists of up to five stands in 18-HS design plus a powerful pinch roll unit on the exit side. Also designed for continuous operation, the runout section features a double tension reel.

All 18-HS mills can come with our CVC® plus technology. Using the special CVC® plus roll contour means you can correct more severe flatness defects over a wider range than with other approaches. You also benefit from easy, fast work-roll and intermediate-roll changing.

![]()

18-HS TCM Posco -

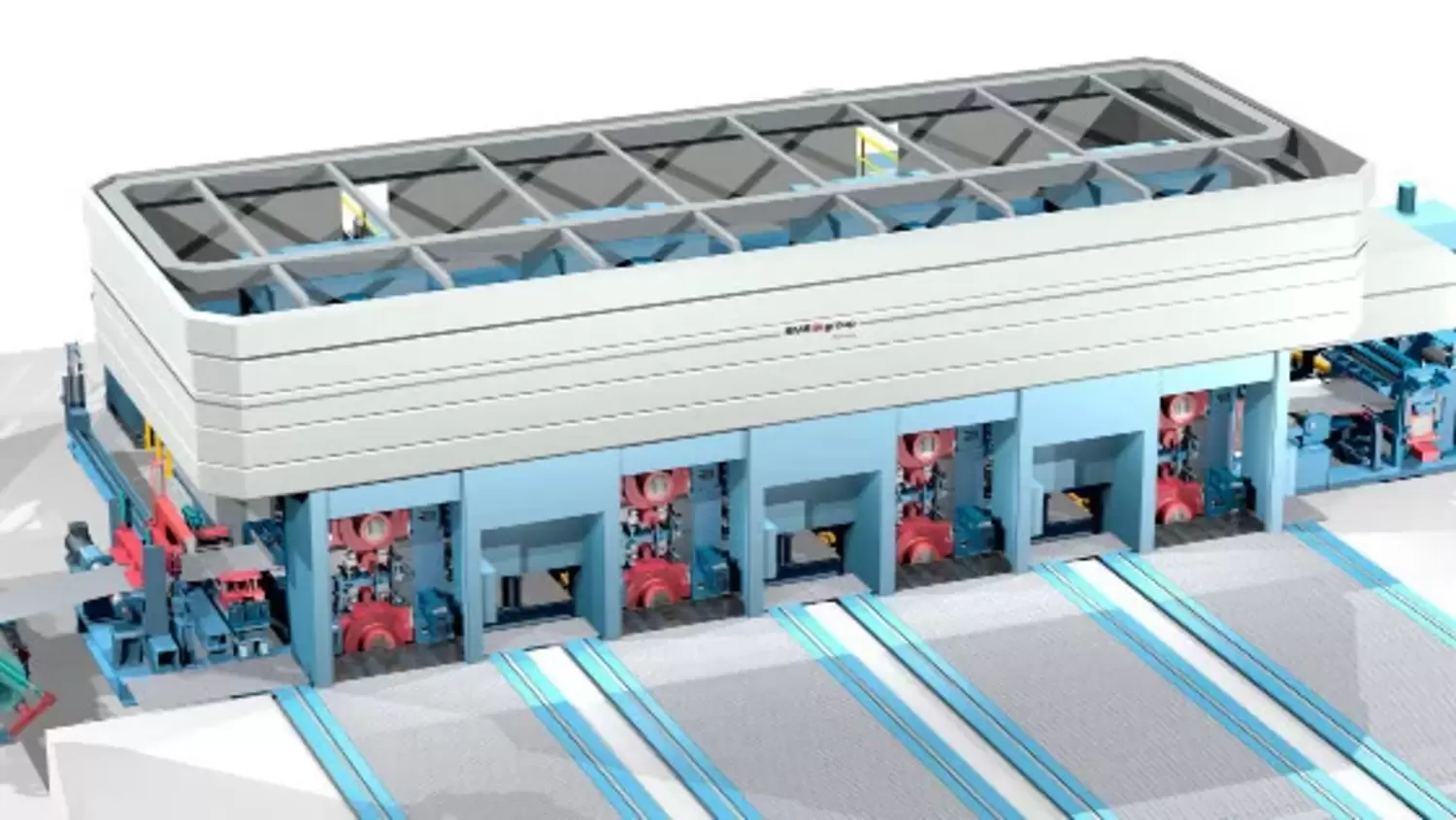

18-HS mill in a rolling, annealing and pickling line (IRAPL)

Integrated plant concept for continuous production

Main dataThere are substantial advantages to assembling integrated lines that combine the main process steps rolling, annealing and pickling (IRAPL) in a continuous production flow. The essential elements in the entry section are a pay-off-reel unit, a welding machine, and an entry strip accumulator. Next in line is a tandem mill in 6-high or 18-HS design with up to five stands, a strip cleaning section, another strip accumulator, an annealing furnace with cooling section, and a pickling section with strip accumulator. Finally, the exit end features strip finishing equipment such as a skin pass mill, tension leveler, creep looper, inline inspection area, tension reel, coil strapping, and coil weighing machine.

![]()

IRAPL -

Skin-pass mills for stainless steel

Applying a gloss finish to stainless steel strip

Main dataThe next stage after cold-rolling and recrystallization is skin-passing the stainless steel strip. This produces high-gloss surfaces and achieves the desired mechanical strip properties such as deep-drawing strength. Skin- passing is mainly performed on 2-high reversing mill stands. What’s evident today is that customers are increasingly choosing 4-high designs. You can also opt for a combined 2-high and 4-high stand solution.

There are two versions to suit various plant configurations: inline skin-pass mills are integrated in the annealing and pickling line and/or the bright annealing line, while offline mills are installed downstream.

![]()

Stainless steel skin-pass mill

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

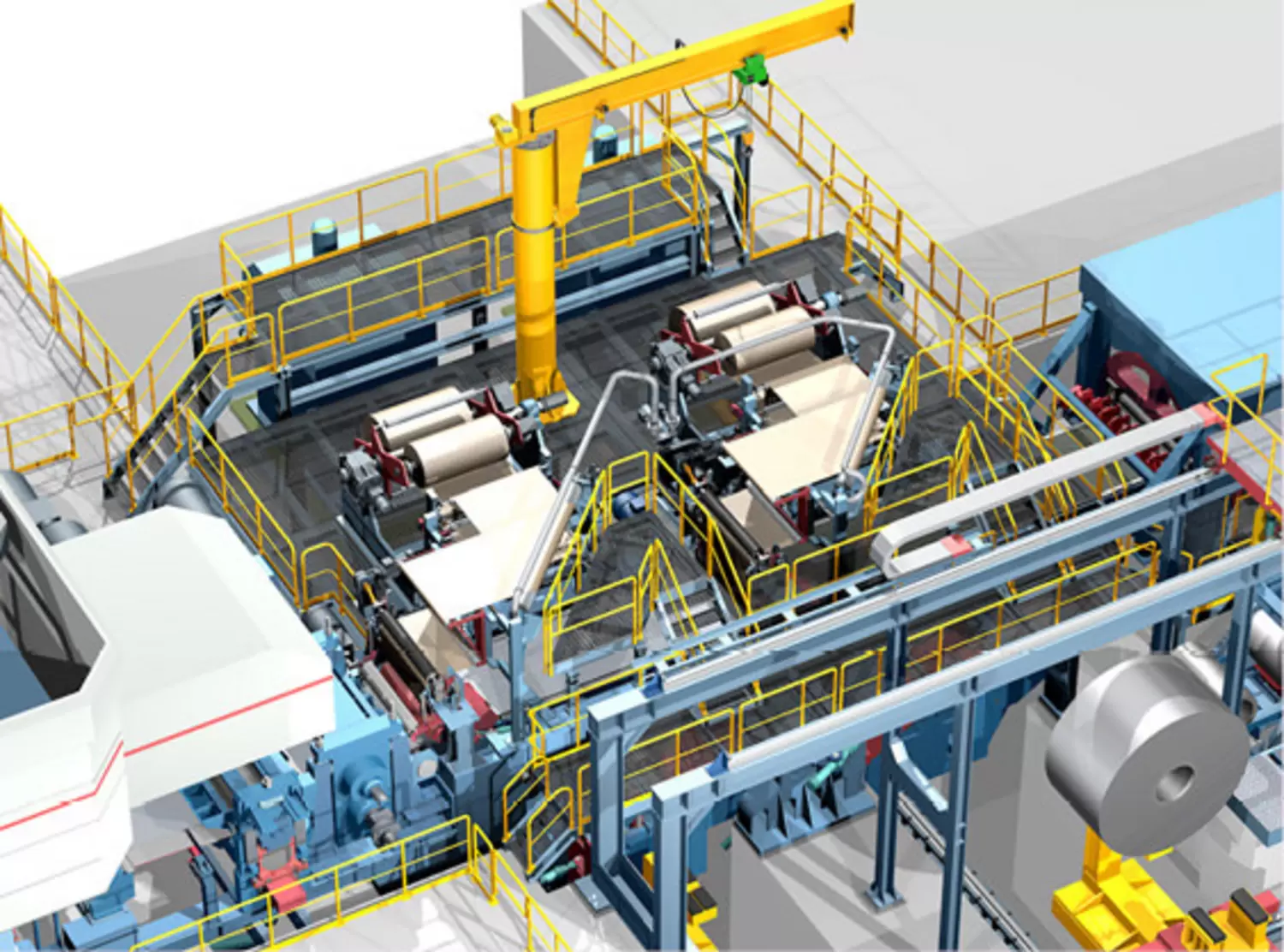

Carousel-type automatic paper dispenser

Protection of high-grade strip surfaces by continuous paper feed

It's vital to protect the finished strip surface. That's why the coils are wound with an intermediate paper layer. Naturally, continuous rolling process requires a continuous paper feed: our carousel-type automatic paper dispenser. Included among the stand-out features is the automatic paper-roll-changing system.

![]()

Paper dispenser -

Multipurpose mill CVC® plus M 18/4

Flexible production of soft and high-strength materials on one mill

It's a huge challenge to produce smaller batches profitably, especially when not running the mill at full capacity. Our new CVC® plus M 18/4 stand for reversing and tandem mills is a multipurpose mill that covers a very wide product range from soft IF-grades (Interstitial Free) right through to HSS (High Strength Steel) and stainless steels.

We install the CVC® plus M 18/4 multi-function stand type in both new and existing mills. Central to this equipment is a rapid and easy-change roll set in CVC plus 4-high and 18-HS design. That ensures you can expand your product range at low cost.

Benefits

- CVC® plus 4-high and 18-HS design combined in one mill

- Applicable for RCM and TCM

- Flexible production from soft to high-strength material

- High reductions

- Operating mode changeover within just seven minutes by changing the complete roll cassette

-

Rotary Inspect

Reliable, ergonomic and therefore efficient strip surface inspection

Rotary Inspect is the most advanced exit-side inspection line for tandem cold mills. Whether you use it in inline or offline configurations, this solution rapidly detects all strip surface defects on both sides of the strip. That means you get fewer inferior-quality coils. You can use Rotary Inspect with all reel configurations.

Main features of rotary inspect:

- Inspection platform, strip clamping, and turning device

- Sample cutting at rolling speed of 150 meters per minute or higher

- Contact-free, 360° turning of clamped sample, Position free selectable

Benefits

- No additional surface marks caused by sample turning or moving

- Easy, cost-effective, and safe handling

- Fast and reliable inspection of both strip sides

- Fewer downgraded coils

-

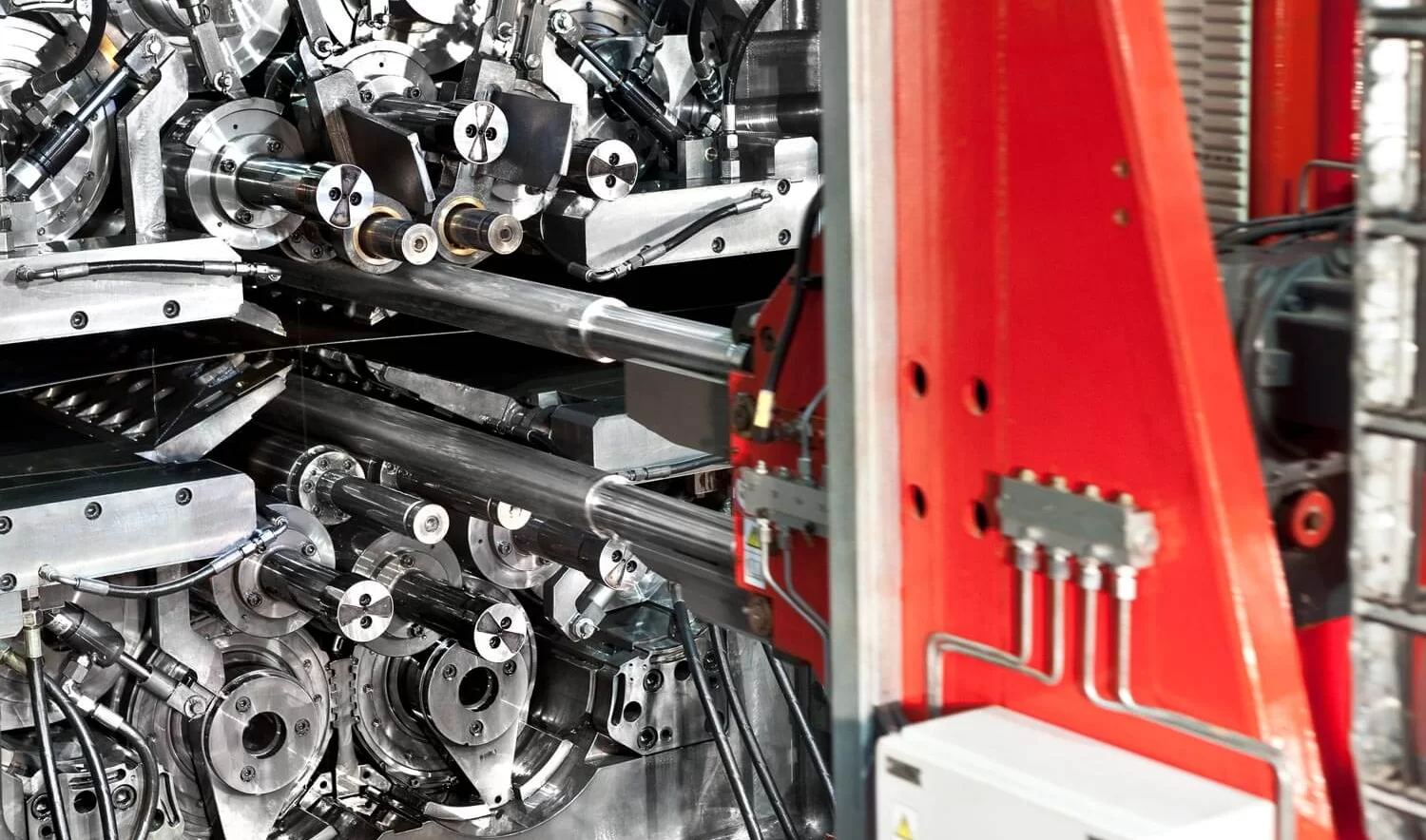

High-end actuators, controls and support systems

Top rolling technology for top products

You face constantly increasing demands on product quality and production efficiency. That’s why we equip our stainless steel mills with a package of high-end rolling technologies so you can rely on smooth production and high yields. Included in these solutions are roll-gap actuators, thickness and flatness control, and advanced support systems.

![]()

Roll gap Monoblock mill -

Roll change robot

High-speed roll changing

What saves you money is our equipment that cuts non-productive. For roll change, you can choose between semi-automated and fully automated systems. The most advanced option is the high-speed roll change robot for Splitblock 20-high mills. It consists of a robot for reproducible optimized work-roll and intermediate-roll changes.

![]()

Roll change robot -

Modular design

Shorter erection and commissioning times for 20-high mill stands

Characteristic of our 20-high mill stands is the large share of in-house manufacturing. Prior to delivery to customers, the stands are completely preassembled in our Hilchenbach workshops in Germany, including piping and cabling. Due to their modular design, the mills can be shipped in a single delivery.

Just as conveniently for you, our hydraulic systems are also modular, with compact pump systems and control elements. That makes them particularly operator-friendly and low-maintenance. Combined with functional testing, all this guarantees hitch-free installation and commissioning so you can start production in no time. That also ensures you get an early return on investment.

Modular elements

- Mill stand

- Media platform with hydraulic valve stands

- Entry section

- Exit section

![]()

Pre-assembly 20-high mill stand -

Supafine® filter system

Ideal for fine-filtering rolling oil

Our Supafine® filters are designed for micro-filtration of the low-viscosity mineral oils applied in cold rolling stainless steel. Supafine® filters do not require any filtering agents – unlike older pre-coated cartridge filters, which can cause problems during disposal.

Our Supafine® filter elements represent the currently most up-to-date solution for fine filtration – it is based on micro-fiber elements. Supafine® filters do not require filtering agents, thus avoiding non-recyclable waste products such as diatomaceous earth. With a view to environmental protection and the reduction of operating costs, it makes sense to retrofit a Supafine® filter system as part of a revamp.![]()

Supafine® filters Benefits

- Extremely high cleaning efficiency

- Low operating costs due to less maintenance expenditure, no filtering agents, low rolling oil losses and few waste materials

- Long service life of filter elements

- No risk of break-out of filtering agent on the clean oil side

- High operational reliability due to fully automated system