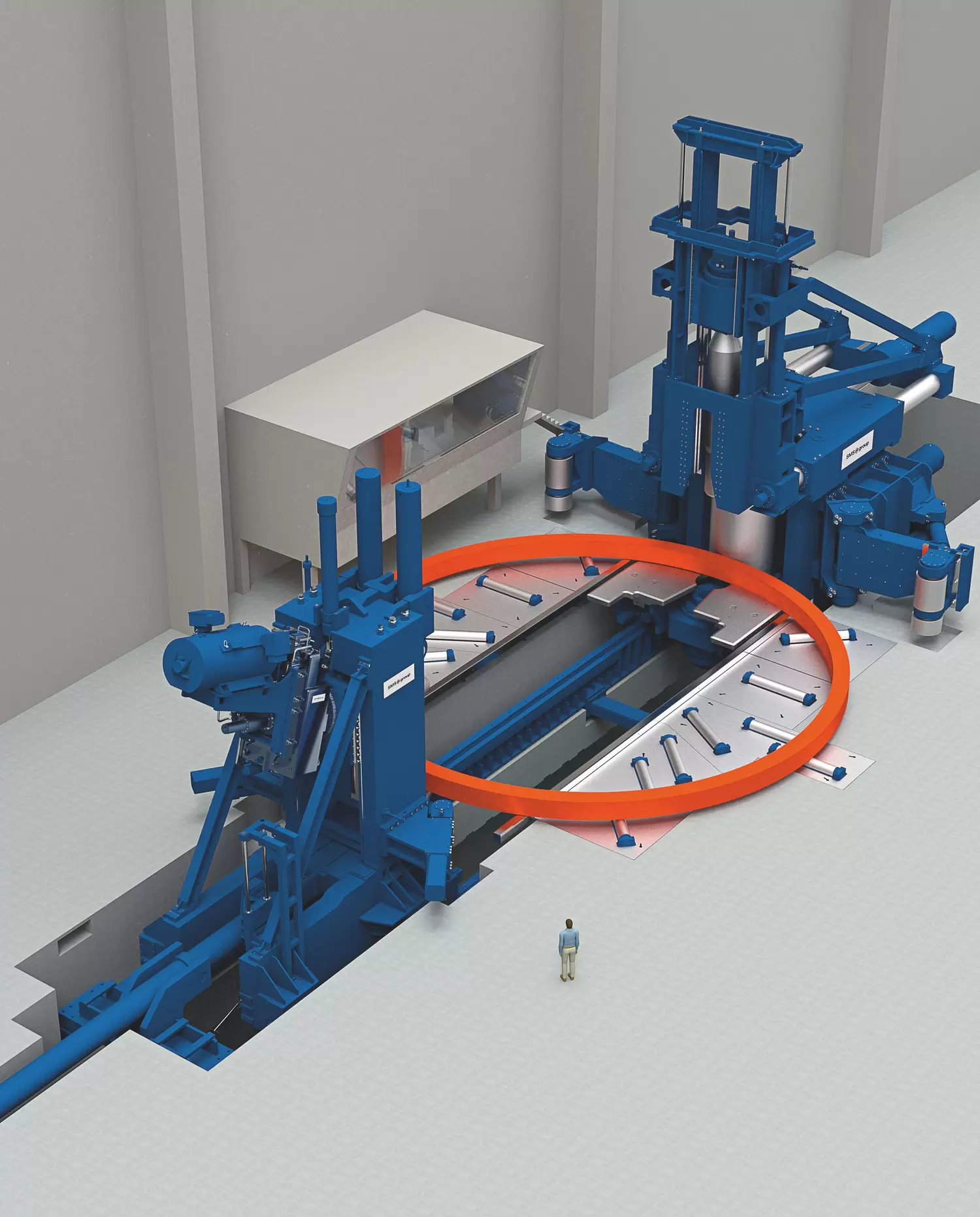

With the radial-axial ring rolling machine of the RAW 2500/1250-16000/3000 type, production takes place in completely new dimensions. The rings produced on this machine are employed among others in towers of wind power plants and they are capable of withstanding extreme stresses to which those large wind power plants are exposed. Another application of rollable rings are large shells necessary for the construction of large pressure vessels e.g. in nuclear reactors.

Joint venture

SIHI is a European-Chinese joint venture, with the Spanish enterprise GRI Renewable Industries holding a 50 percent share in this joint venture and having been significantly involved in the realization of this project. In keeping up with the requirements of customers and markets, GRI is a major global manufacturer of towers for wind turbines operating production facilities worldwide for the manufacture of towers in all required sizes. In the supply chain, SIHI acts as a producer of tower flanges of all required sizes also developing further its production capabilities with the machine now delivered by SMS group.

Engineering and design phase

The contract between SIHI and SMS group was signed in May 2016. From the very beginning, the order for the ring rolling machine faced a scheduling challenge. Only 22 months after the contract coming into force the first hot ring should be rolled in China. For handling this demanding machine and for complying with this ambitious time schedule SMS group put together an experienced and well-coordinated project team. To ensure successful commissioning a virtual startup was performed in advance. In this case, a completely virtual machine and ring model served as a basis and all programs and functions involved in the rolling process could be tested and optimized on a physical realtime model.

In-house assembly

The ring rolling machine was pre-assembled at SMS group’s German location in Mönchengladbach where also several large components were machined. For the individual assembly steps and the working sequence high component weights had to be considered at all times. The ready-assembled radial component alone weighs about 1,300 tons and the axial component is weighing roughly 530 tons.

In just four months, the SMS experts succeeded in completing the installation of the main machine assembly groups. Thereafter, the machine was dismantled into transportable assembly groups and supplied to the construction site. Despite the ambitious time schedule, all working steps took place with utmost care, quality and precision.

On-site assembly

In parallel with in-house assembly in Mönchengladbach, onsite assembly was launched in China on schedule. As a first step on site, the frame side parts onto which the machine is placed at a later stage were put on the foundation and then aligned. Furthermore, the prefabricated foundation pipe sections were inserted, the cable paths in the foundation were enlarged and the switchgear was set in. The radial gear and the drives in the foundation had also to be placed. Within only ten weeks – in record time for this machine size – the complete assembly was finalized including machine piping and cabling. A seamless transition into commissioning could therefore be ensured which had already started in parallel with final assembly activities.

Commissioning, first ring and acceptance

On April 17, 2018, the first hot ring could be successfully rolled on the new radial-axial ring rolling machine of the RAW 2500/1250-16000/3000 type. Due to further optimizing the adjustments and the rolling programs, a new world record for the ring diameter of 15.6 meters could be set on May 22, 2018. Thus, SMS group could set an important technological milestone demonstrating once again its world leadership in this highly demanding forming technology.

Opening ceremony

On May 30, 2018, Shandong Iraeta Heavy Industry Co., Ltd. had invited to a grand opening ceremony. On that occasion, the new ring rolling machine was officially presented to 200 invited guests from business and politics.