Demand oriented copper wire rod production

More than half of demand on the copper market is for cast and rolled copper wire rod. That's because this material is crucial to the electrical and electronics industry. We have banked decades of experience and obtained worldwide references. Thanks to modular design, we are able to realize our CONTIROD® (a registered trademark of Aurubis) and compactROD® plants according to your desired end product characteristics.

-

CONTIROD®

Combined casting and rolling lines for wire rod

Main dataCONTIROD® copper rod plants impress with their high efficiency and production flexibility. The success of our CONTIROD® technology is based on innovations in melting, casting and rolling process. CONTIROD® is the only manufacturing process for cast wire rod that utilizes a Hazelett twin-belt casting machine. A decisive factor behind the excellent product quality is the near horizontal casting method that can physically preclude porosity in the casting bar's core. The well-proven CONTIROD® rolling mill with individual drives shapes the casting bar into fine-grained copper wire rod. The completely overhauled cooling section features two separate media circuits and provides the basis for the high-quality wire rod surface. In the first phase, the wire rod is deoxidized by treating it with a water-alcohol mixture. It is then cooled down further with water.

Our CONTIROD® plants are equipped with the latest technical solutions for producing high product quality at the lowest process costs. A large number of sensors and control elements work in conjunction with the specially developed software to ensure high process reliability and reproducible quality.

*CONTIROD® is a registered trademark of Aurubis Belgium

![]()

-

compacROD®

Compact copper wire rod plant

Main dataThe modular compacROD® plant from SMS group is the cost-effective solution for the production of copper wire rod in volumes of around 30,000 to 50,000 tons per year. This new type of plant is where SMS group benefits from its extensive experience and expertise in copper wire rod plants featuring the latest melting and rolling technology combined with a demand-oriented casting system. Consistently high product quality and low process costs mean plant owners are assured of long-term success.

![]()

Compacrod plant layout

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Rolling mills

Optimal production results at the center of the plant

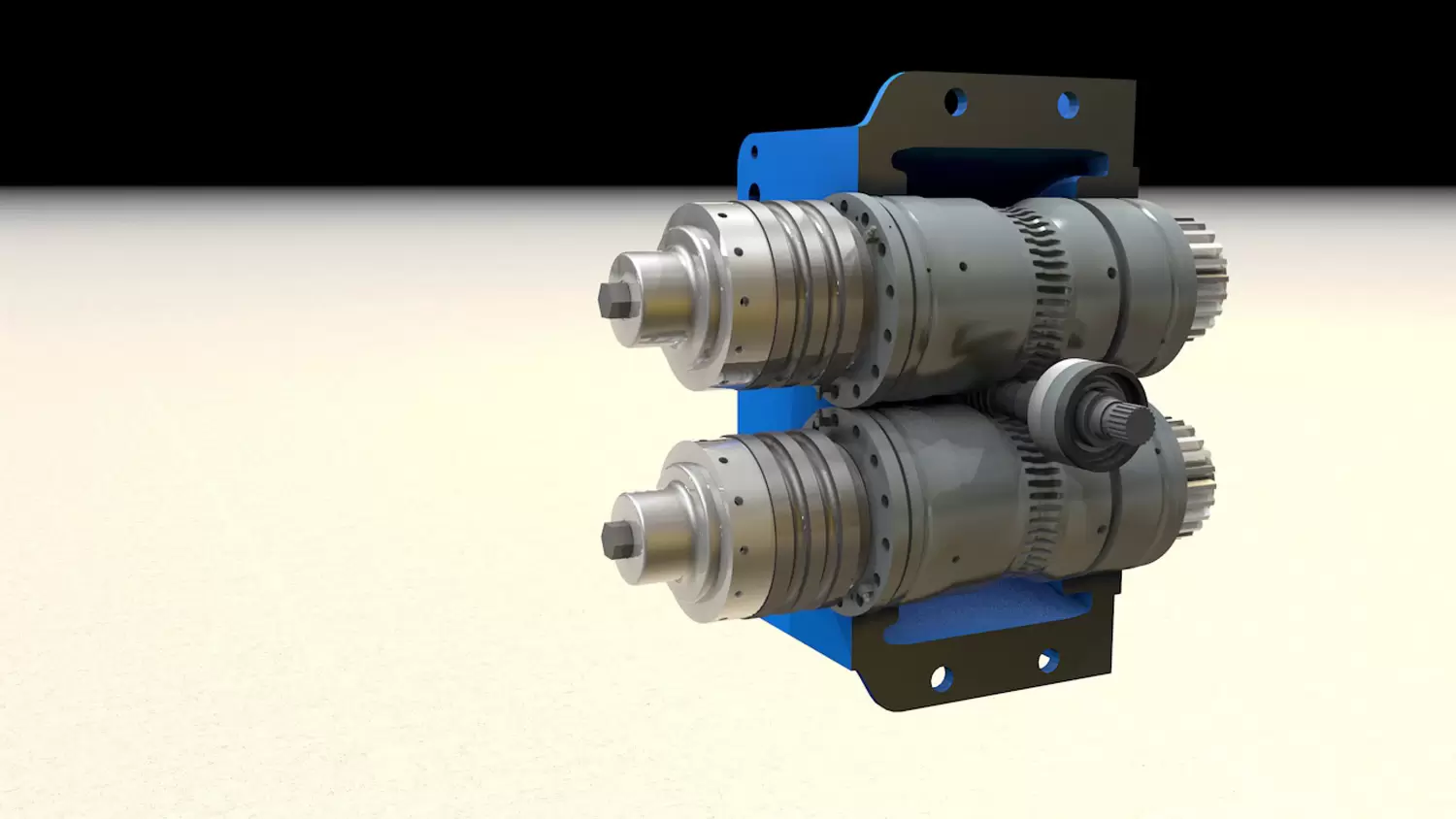

The centerpiece of our copper rod plants is the rolling mill. Especially important is our individual drive technology.

![]()

Rolling mill for copper Benefits

- Better rolling quality due to separate drive for each roll stand

- Fine-grained, homogeneous rolling structure

- Low process costs for roll rings due to less wear and tear

- High flexibility regarding final product dimensions for both round and flat sections

- Less maintenance and low energy consumption due to robust, frequency-controlled AC motors

-

PLC systems

Intelligent technology package

It's easy for your plant operators to control the entire copper rod plant using our PLC (Programmable Logic Controller) systems. Included here is visualization with diagnostic signaling and monitoring software. That eliminates any problems and potential interruptions before they even start.

![]()

Control room shaft furnace