SMS group supplies plant technology for the production of high-quality metal powder for Additive Manufacturing (AM) and other technologies. By operating a pilot gas atomization plant (VIGA - Vacuum Induction Gas Atomization) integrated in the SMS 3D-Test Center, the SMS group has optimized the classical powder production for the requirements in AM over the last years.

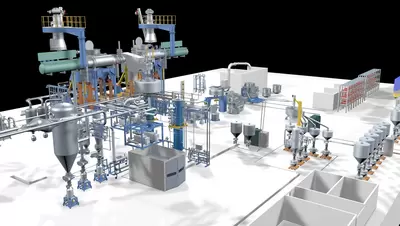

In addition to conventional gas atomization plants, the SMS group, together with a customer, has developed another highly innovative powder production process. The conventional batch-wise process is transformed into a continuous process. The Continuous Powder Production Plant enables cost-effective and large-scale production of up to 4,000 tons per year. Compared to the traditional Gas Atomization process the capacity is increased by a multiple. The integrated plant was developed to meet the rapidly growing demand for metal powders and the growing cost expectations in the market. Production costs for spherical, high-quality metal powders are significantly reduced. Cost-effective and high-quality powders will be one of the main drivers for the development of metal AM towards a sustainable industrial technology. The increase in capacity results in enormous economies of scale. Set-up times, melting and cooling times are reduced. Overall, this results in significant reductions in CAPEX and OPEX costs producing one ton of powder. In the new process developed by SMS group, two large Vacuum Induction Melting (VIM) furnaces continuously hold liquid melt, which is atomized successively through the nozzle. The nozzle can be exchanged during operation. Melting is done under vacuum to guarantee highest quality levels like in the conventional process. In addition to the VIM route, where pure scrap is used as feedstock, the new process can also work with an existing liquid material supply. A metallurgical route with basic scrap as feedstock is also possible. The new process is backed up by an intelligent powder handling and storage system, as well as automatic packaging solution. A scrap warehouse and a packaging area complete the integrated factory solution.

Contact: Yannik Wilkens