SMS group offers various plant concepts for the secondary metallurgical refining of liquid steel. These state-of-the-art plants enable you to meet your high demands for final product quality. Following your specific requirements, we design tailor-made solutions for your metallurgical, logistics, and productivity challenges.

-

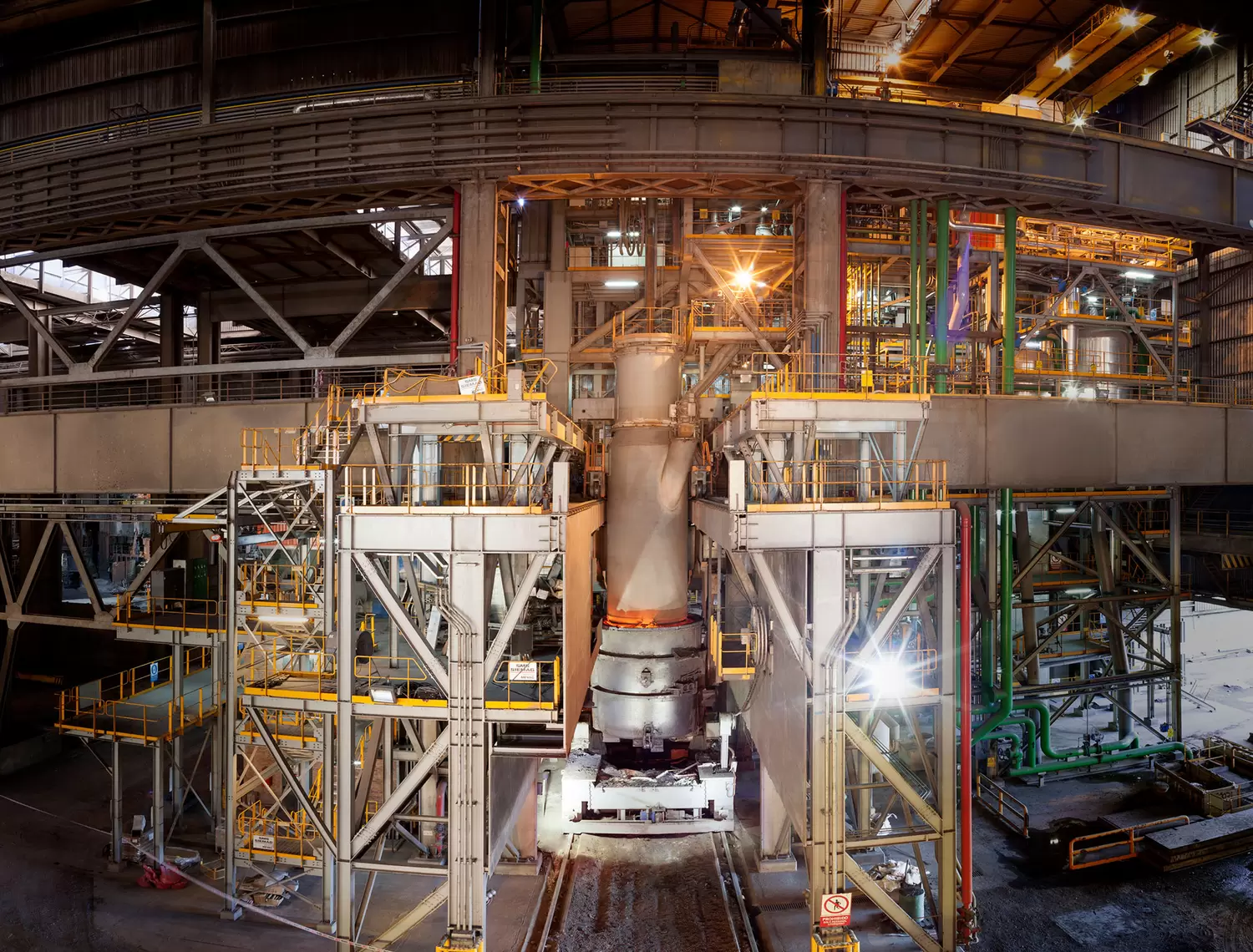

Ladle furnace technology

Solution for quality metal production

With more than 500 ladle furnaces in new constructions and revamp projects, SMS group ranks among the world’s leading suppliers of ladle furnace technology.

SMS group’s ladle furnaces and optimized processes offer the most cost-effective solutions, resulting in high productivity at low production costs. All components of the ladle furnace technology from SMS group have also been developed with the aim of reducing the cost of steel production. This makes investment pay off faster.

Benefits

- Modular design based on process and layout, optimized CAPEX

- Low maintenance due to standardized component groups

- Lower production costs

- High quality steel production

- Optimizing CO2 footprint of process flow

![]()

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

RH plant (Ruhrstahl Heraeus process)

Secondary metallurgy under vacuum conditions

With more than 180 plants and heat sizes of up to 400 tons, SMS group’s RH process is characterized worldwide by very good results in decarburization and degassing with relatively low temperature losses. It is particularly suitable for melting processes with short cycle times.

No special slag measures, additional ladle freeboard or purge plugs in the ladle bottom are required for the RH process. Fast vessel changes and efficient ladle transport concepts increase the capacity of a plant, and with the use of a duplex system, the capacity can be increased even further.

The following features characterize the RH process:

- Decarburization to lowest final contents

- Rapid removal of hydrogen

- Alloying and fine trimming with high accuracy and very good yield

- Fast addition of large quantities of alloy

- Rapid homogenization of the ladle contents, even when adding large quantities of alloy

- Very short treatment times with the vacuum carbon deoxidation type

- Relatively low temperature losses (depending on the batch size)

![]()

RH plant -

Vacuum tank decarburization

Secondary metallurgy under vacuum conditions

The VOD process (Vacuum Oxygen Decarburization) from SMS group has been successfully used in the production and refining of stainless and acid- and heat-resistant steel since the end of the 1950s. To date, more than 100 plants with heat sizes of up to 200 tons have been built using this process. It is used to achieve particularly low carbon contents in an economical way, as the oxidation of chromium is significantly reduced by blowing oxygen for decarburization under reduced pressure. The consumption of reducing agents is also considerably lower.

A VOD plant can be used in a duplex line (EAF – deslagging – (LF) – VOD) immediately after the melting unit or coupled with an AOD converter in a triplex line (EAF – AOD – (deslagging) – VOD). Especially for the production of stainless steels with the lowest carbon contents, such as superferritic steel grades, the VOD process is without alternative.

Our VOD plants are designed to meet the specific requirements of the production program, the timing in the steel mill, and the individual process of our customers. Each VOD plant can also be used as a VD or VD-OB plant.

![]()

VOD plant