SMS group is the system supplier for all significant line types for stainless steel strip processing, from annealing and pickling lines for hot or cold strip to integrated rolling, annealing and pickling lines as well as bright annealing lines. The goal of energy-efficient production with maximum process-oriented power supply performance motivates customers to collaborate with SMS group in replacing conventional thyristor systems with advanced IGBT technology-based switched-mode power supply units. This forward-looking IGBT technology enables customers to achieve more sustainable production and significantly improve results in the pickling section and in the quality of the steel surface treatment, for example.

Forward-looking technology for a more sustainable electrolytic process

X-Pact® High Current is an innovative solution that is not only technically and economically outstanding but also boasts high energy efficiency levels (over 94 percent) over the entire working range. The efficiency of the switched-mode power supply units is considerably higher than that of traditional thyristor DC power supply systems. Used in daily production processes, the rectifiers are designed to meet maximum requirements and are often operated at partial loads. It is during partial load operation that the advantages of switched-mode power units in terms of energy consumption become particularly evident compared to conventional thyristor devices. Energy savings of more than 40% are possible, especially when compared to older thyristor DC power supply units, meaning lower costs and CO2 footprint.

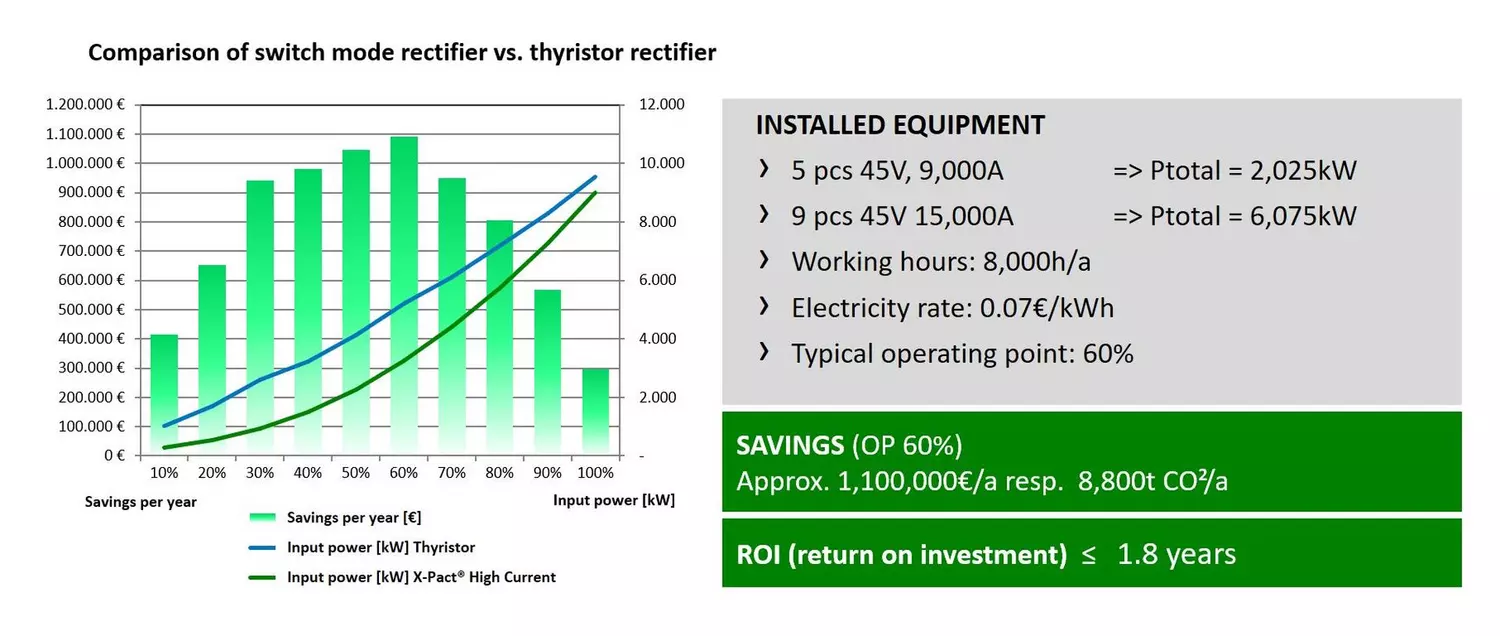

The figure below shows an example of energy savings in an annealing and pickling line for stainless steel, with an electricity price of seven cents/kWh and an operating point of 60 percent of the installed rectifier power. The green bars show the annual potential savings at the corresponding operating point.

The blue graph depicts the incoming power of the installed thyristor system, while the green graph represents the incoming power of a switchgear system following a revamp. By replacing the thyristor DC supply with an SMS group switched-mode power supply solution, it is possible to achieve annual savings of approximately 1.1 million euros. The investment in X-Pact® switched-mode power supply systems, including equipment, disassembly, and assembly, sees a return on investment of less than 1.8 years, which is considered excellent in the metals industry.

Increased plant availability

Due to its modular design, switched-mode power units X-Pact® High Current improve availability and reliability of the stainless steel lines by allowing defective modules to be easily replaced quickly and effortlessly. In the event of a failure of modules or towers, other modules take over automatically, which significantly increases availability compared to the previous systems that are based on individual towers. Individual switched-mode power supplies can be connected in parallel to increase the current at the process tank. Linking several modules not only increases the availability of the direct current/voltage supply but also enhances the reliability of the entire line.

The innovative design makes the system ideal for new plant installations, upgrades, or replacement investments. They also generate less mains feedback, improve power factor and cos phi, and offer superior control with significantly lower residual ripple below 5%, and even below 3% or 1%, compared to around 7% for unfiltered thyristor devices.

Pulse/pulse reverse plating

In addition to the advantages mentioned, the pulse/pulse reverse plating functionality offers an additional, powerful tool. Thanks to the possibility of specifying freely selectable pulse patterns of the DC current, this technology can be used for the further development and optimization of different processes. This is a benefit that will continue to have a positive influence on its development in the near future.

Integrated solutions for efficient stainless steel lines

With its integrated solutions, SMS group brings together all the necessary expertise and competencies under one roof, taking full responsibility for project outcomes, whether it's a new plant or a revamp. Despite the very low system perturbation with X-Pact® High Current switched-mode power supply units, a network analysis should always be conducted due to the high overall output. To avoid network problems during or after commissioning, SMS group has the capability to conduct these checks in-house thanks to its extensive experience in metallurgical plant engineering.

SMS group also specializes in modifications and maintenance across mechanical systems, such as strip steering, drive systems and components, and offers holistic X-Pact® basic and process automation packages that increase the efficiency of modern stainless steel lines. Comprehensive project management expertise rounds off SMS group's holistic concept.