Machinery to draw, peel, and grind bright bar

Bright bars are synonymous with clean, smooth surfaces, high dimensional accuracy, and amazingly low production costs - properties that make bright bars valuable to many industries. For example, bright bars are used in the automotive industry for steering and drive components, piston rods, and suspension springs. But bright bars are also indispensable in mechanical and plant engineering as well as in medical technology.

SMS group has more than 80 years of experience in the manufacture of machines for drawing, peeling, and grinding bright bar. This knowledge goes back to the traditional brands SCHUMAG and KIESERLING, which have been part of SMS group since 2008.

-

Drawing lines

Individual machines, ideally combined

Main dataSMS group offers you high-performance, combined drawing lines for round, square, hexagonal, and special-shaped bars. Starting from safe loading of the uncoiler through to the finished bar bundle, our engineers ensure your line components are perfectly tailored to your specific requirements. Depending on your application, you can choose from two types of continuous drawing systems: conventional cam-type drawing machines and chain track drawing machines. Both guarantee optimal production efficiency and high-quality finished products.

We supply a full range of upstream and downstream equipment to form integrated drawing lines – with a firm focus on overall plant performance and safety. Our uncoilers, smart coil opening systems, and pre-straightening machines ensure perfect raw material preparation.

Next there is our line of drawing units, renowned for their standout features such as unparalleled reliability, remote die control under load, and high drawing speeds. Also available for you are high-precision flying shears, straightening and polishing machines, bar end processing units, and inspection equipment. You can also integrate other systems for descaling, packaging, etc. if you wish. Summing up: Our world-class experts will offer you the right machine for every application.

![]()

Layout of a drawing line by SMS group -

Peeling lines

One machine for every application

Main dataSMS group supplies both standalone peelers and complex integrated peeling lines featuring a maximum level of automation. Included here are bar-to-bar and coil-to-bar operating modes for cylindrical, conical, and double cone bars, as well as coil-to-coil operation. Always at the heart of these bright steel centers is our PM (peeling machine) technology, which ensures you achieve the highest standards in quality, productivity, and flexibility.

You can choose from three different series, with working ranges of between 5 and 630 mm diameter:

- PM series for top performance and quality

- WDH series for cost-effective production of small batches

- PMH series for large bar diameters and forged products

These peelers are known as the best in their class in terms of productivity, automation with recipe control, durability, and product quality. Furthermore, they offer bright steel producers an excellent return on investment. Also incorporated in our peeling line program are bar handling equipment, straightening and polishing machines, bar end machining, and inspection and packaging equipment. Whatever you choose from this program – it will be geared specifically to the peeler performance.

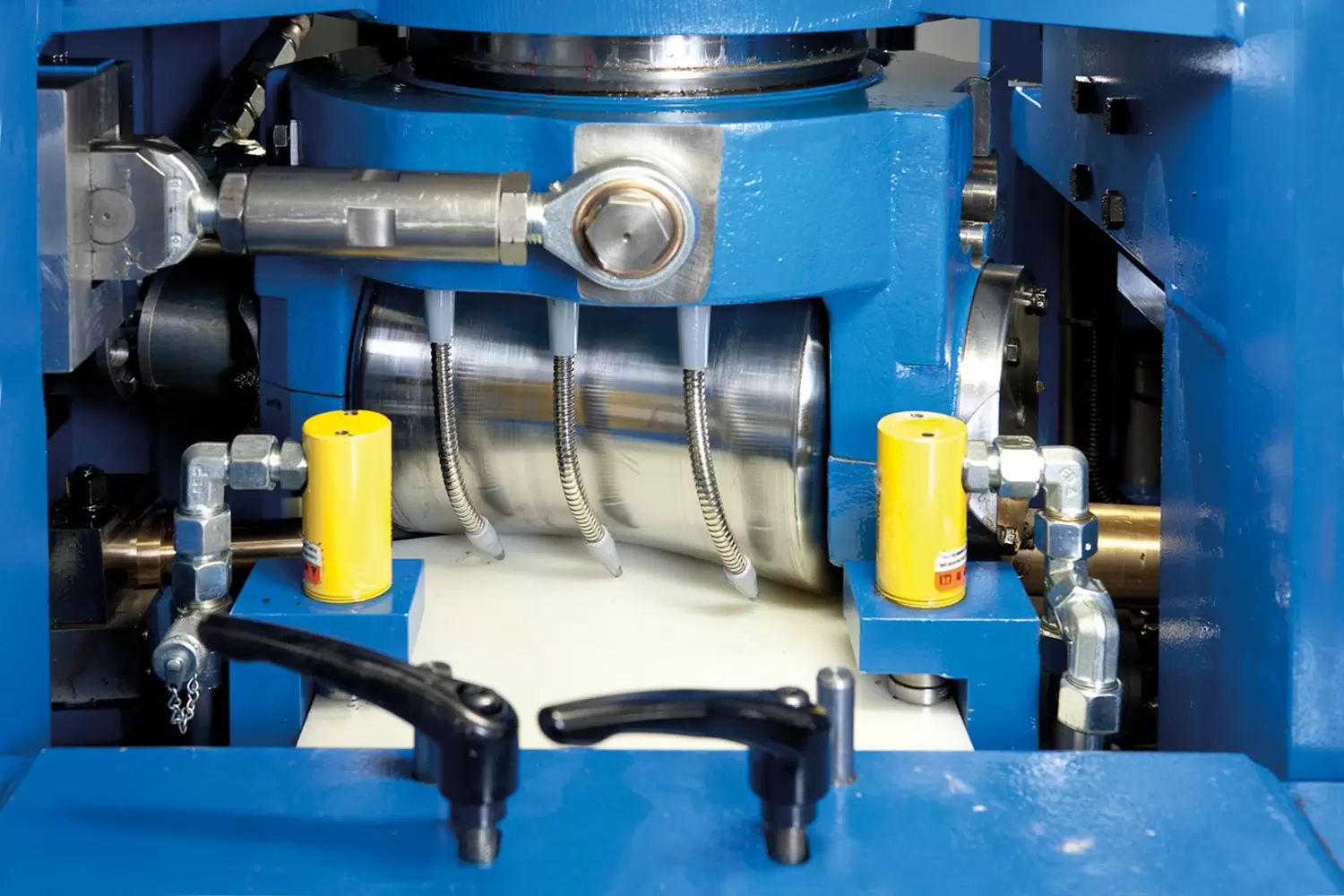

![]()

Close up of a peeling line by SMS group -

Bright bar straightening lines

Designed for high bar straightness

Whether two-millimeter thin wire or anything up to formats a hundred times larger – SMS group supplies the right straightening solution for all your long products. Especially crucial for the straightness of bright steel bars are, for example, piston rods and printer feed shafts.

Our WRP B series two-roll straightening and polishing machines are designed for particularly high-tensile materials and tough specifications. Most of the adjusting and clamping operations are performed by motors or hydraulics.

That allows the machines to generate the best possible straightening results over the full bar length, within a diameter range of between 4 and 250 mm. What’s equally impressive is that these machines are so fast they achieve feed rates of up to 210 m per minute, which translates into high productivity. You also benefit from features such as quick-change systems, engineered roll contours for special materials, and recipe control for quick setup.

The WRP E series, on the other hand, is a cost-effective solution for low to moderate tensile strength material and bar diameters of between 4 and 60 mm. A number of machine parameters are set manually. You can integrate these systems in bright bar lines or as standalone units with suitable bar handling systems.

![]()

Close up of a bright bar straightening line by SMS group

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

Services for this plant

Sorry, there are no results for the search term.