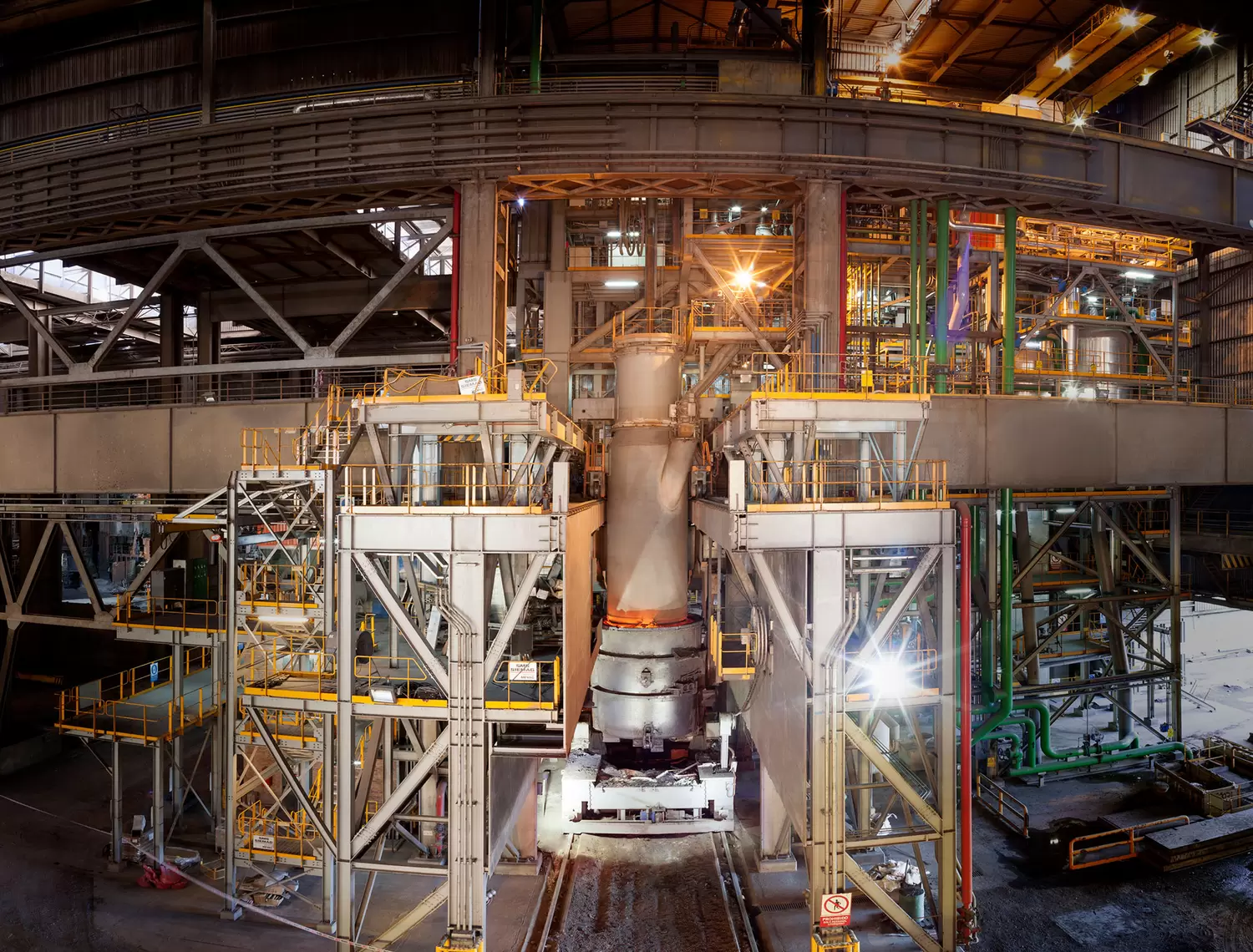

RH plant (Ruhrstahl Heraeus process)

Secondary metallurgy under vacuum conditions

With more than 180 plants and heat sizes of up to 400 tons, SMS group’s RH process is characterized worldwide by very good results in decarburization and degassing with relatively low temperature losses. It is particularly suitable for melting processes with short cycle times.

No special slag measures, additional ladle freeboard or purge plugs in the ladle bottom are required for the RH process. Fast vessel changes and efficient ladle transport concepts increase the capacity of a plant, and with the use of a duplex system, the capacity can be increased even further.

The following features characterize the RH process:

- Decarburization to lowest final contents

- Rapid removal of hydrogen

- Alloying and fine trimming with high accuracy and very good yield

- Fast addition of large quantities of alloy

- Rapid homogenization of the ladle contents, even when adding large quantities of alloy

- Very short treatment times with the vacuum carbon deoxidation type

- Relatively low temperature losses (depending on the batch size)