AMOVA logistic systems provide you with the entire spectrum of transport, storage and packaging logistics for coils from one source.

-

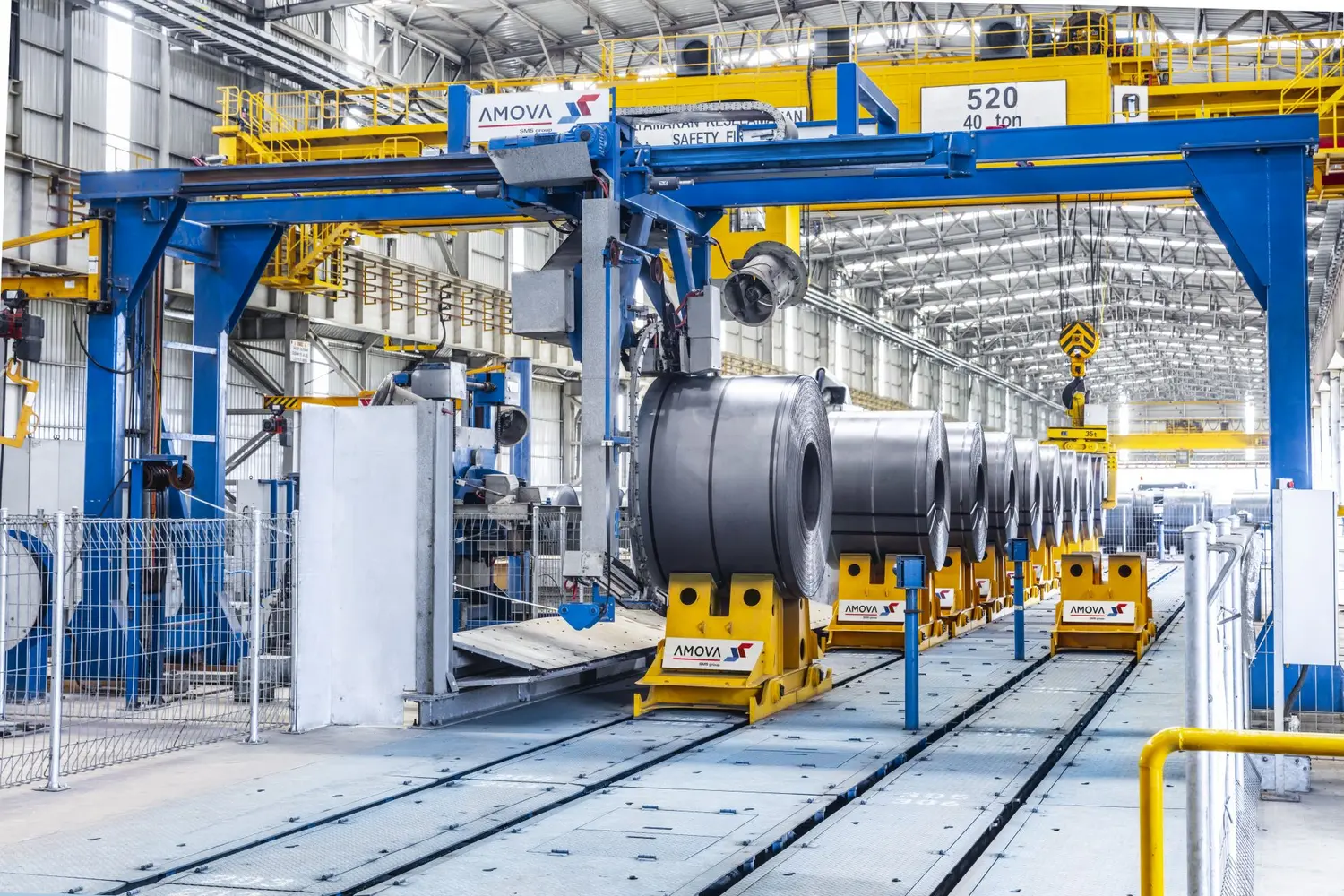

High-bay storage systems

Safe and efficient storage

AMOVA supplies automated high-bay storage systems for heavy loads of up to 50 tons in weight – coils, sheet stacks, slabs, long material as well as other heavy or bulky goods. Numerous references from all over the world testify to our decades of experience in this field. We hold the record for the world‘s largest high-bay store for steel coils, which has not less than 4,300 storage locations.

Our storage systems provide a maximum of efficiency and guarantee optimized dwell and throughput times, protection against material damage, cost-savings in administration and processing, and easy handling and operation.

![]()

-

Flat storage systems

Smooth material flow

We develop individual storage strategies for your particular application and highly efficient concepts even for difficult surroundings and restricted conditions. Our extensive range of customer-specific transport equipment, including AGVs, lift truck systems, and chain and pallet conveyors, ensure a smooth and continuous flow of material and connect the store with production facilities upstream and downstream. Your products are safely transported without sustaining damage.

As a full-service supplier, AMOVA also offers fully integrated systems including conveyor equipment complete with automation and warehouse management system. Our spectrum of products and services extends from initial planning to installation and system startup – we assist you in every phase of your project.

![]()

-

Warehouse management systems

Instant data access

With its extensive range of functions, the WMS is an attractive, reliable solution for automated material flow control and warehouse management.

When it comes to the user interface, our software developers attach particular importance to intuitive operability as well as optimized search and filter functions. Within seconds, the operator can view details about his stock and get information about the current system status. A special highlight is the revised 3D view. Warehouse stock and material transports are visualized in real time - both the current transport situation and the warehouse itself can thus be viewed conveniently and in a visually appealing way.

In addition to the classic functionalities of a warehouse management system, our WMS also offers support in the planning of production processes. If processing steps are defined in advance, the system uses this information to optimize transport and storage strategies. Depending on customer requirements, material transports can also be automatically triggered at the desired time on the basis of previously defined shipping schedules. The scalable client-server architecture allows our customers flexible use and high-performance access to the WMS data. Additional clients can be set up on current Windows PCs in a few simple steps. AMOVA's WMS can be adapted to the most diverse applications and can be easily integrated into IT landscapes due to its external interfaces.

![]()

-

Pallet conveying systems

Perfect transport solution for hot-strip coils

AMOVA pallet conveying systems can be used to transport hot-strip coils reaching temperatures of up to 850 °C at a travel speed of 0.5 m/s.

AMOVA further-developed the usual method of pallet transport for cold-strip lines some years back and adapted it for operation in hot-strip rolling mills. All components were tested and technically optimized. Specially designed roller table segments in modular design are now supplemented by a pallet concept that excludes thermal deformation of the runners.

The system guarantees extremely careful material transport, since after being placed on the pallet the coils are not moved again. It offers great flexibility in routing combined with minimum spare parts stockage; empty pallets are optionally transported away under or parallel to the load conveyor. The pallet transport system is not bound to a fixed cycle. Which means it can also be decoupled from other systems or processes and used as a material buffer. All transport movements are powered by electric motors, so reducing the scope of hydraulic equipment to a minimum. Likewise the outlay for foundation work.

Thanks to standardized component parts and small, lightweight assembly units the systems are easy to assemble, install and maintain. By comparison with other systems an extremely cost-effective solution providing maximum throughput.

![]()

-

High-speed cars

Fast and efficient

High-speed cars (HSC) by AMOVA make a valuable contribution to reliable and careful coil transport in steel and aluminium works. They shift material weighing up to 40 tons at driving speeds of up to 300 m/min. The cars are fitted with satellite dollies and telescope units that lift, lower or move the coil sideways, as required, and so save having to use cranes or stacker trucks. This enables transport to be decoupled from all other process stages and flexibility to be extremely enhanced.

![]()

-

Automatic coil transporters (A.C.T.®)

Gentle coil handling at high throughput rates for coils weighing up to 40 tons

The battery-operated A.C.T.® is an AMOVA in-house development. The vehicle is guided by laser and moves completely autonomously over routes fixed in the route layout. A fleet of several vehicles is controlled by a host computer that ensures that both the optimum route and the nearest free A.C.T.® is selected to perform the current order.

A tried and approved safety system detects both persons and obstacles on the trackway and stops the vehicle autonomously. The system decides autonomously whether a transport order can be accepted and performed or whether it uses waiting times in production to charge the batteries. At semi- or fully automated battery-changing stations fully discharged batteries can be completely exchanged for fully charged ones or can be partly charged when convenient (“opportunity charging”)

![]()

-

Conventional transport systems

Tailor-made solutions

By linking various transport technologies, we realize integrated logistics concepts – from planning through engineering to implementation, including complete automation engineering. AMOVA supplies transport systems for coils, sheet stacks and metal slabs – for material weights of up to 50 tons and cycle times of under 60 seconds. Our customers profit from the high reliability and quality of our products, which are the result of continuous research and development work.

![]()

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

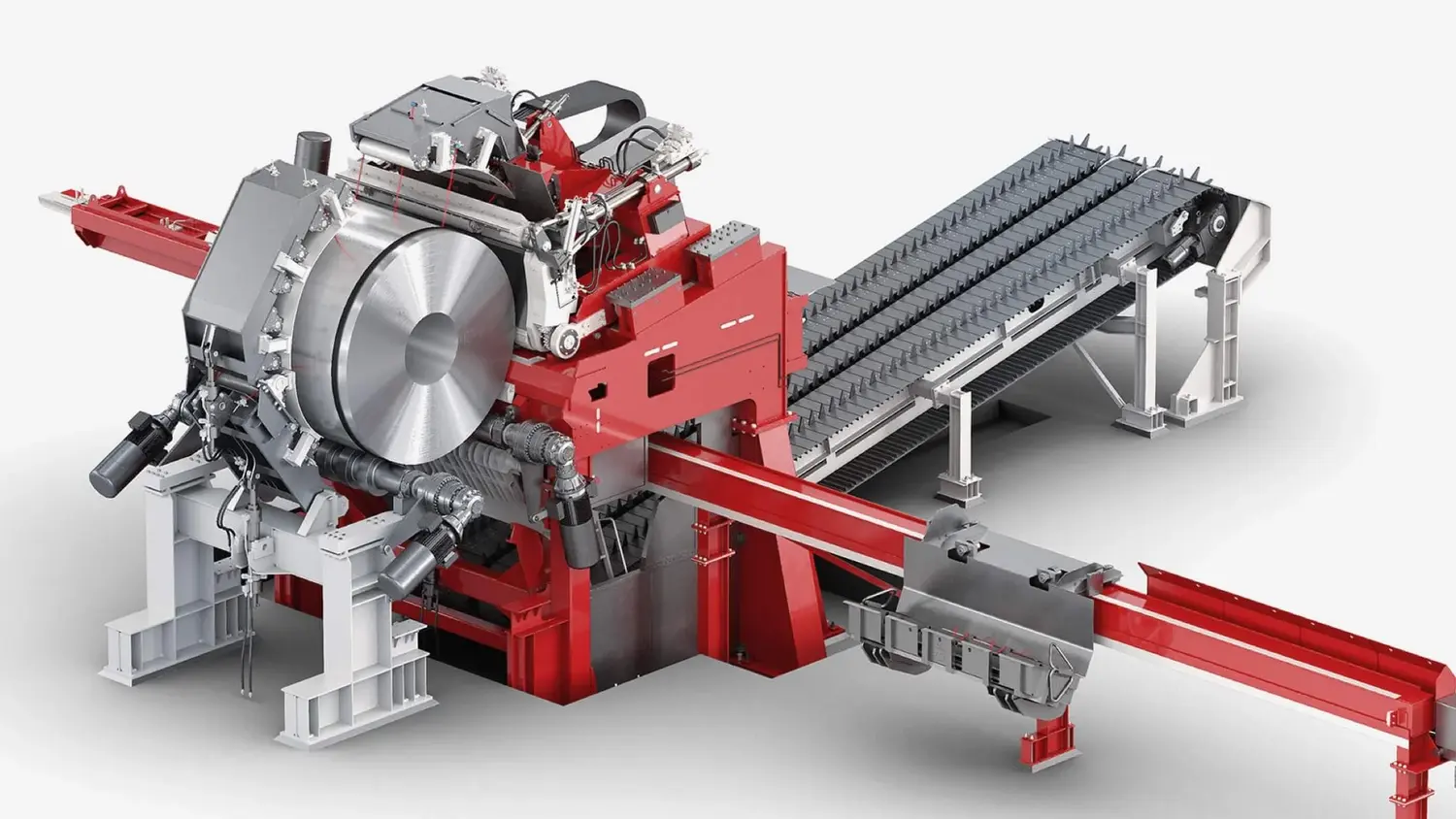

Sampling stations for X-grade steel coils

The optimal solution for high strength steel coils

Steel producers are increasingly responding to market demands for high- to ultra-high-strength steel grades with strip thicknesses of over 25 millimeters. With the fully automatic sampling line from AMOVA, they can significantly increase their production by shortening throughput times. The heart of the line is the high-performance sampling shear in combination with the specially designed transport system and the associated strapping machine. The system concept prevents the high-strength steel strip from suddenly springing open, guarantees safe sampling and reliably secures the coil during handling and transport to the end customer. Thanks to its compact design, the line can be easily integrated into the transport systems of a hot strip mill for the sampling of hot-rolled coils, or into the logistics center for the sampling of cold strip.

![]()

-

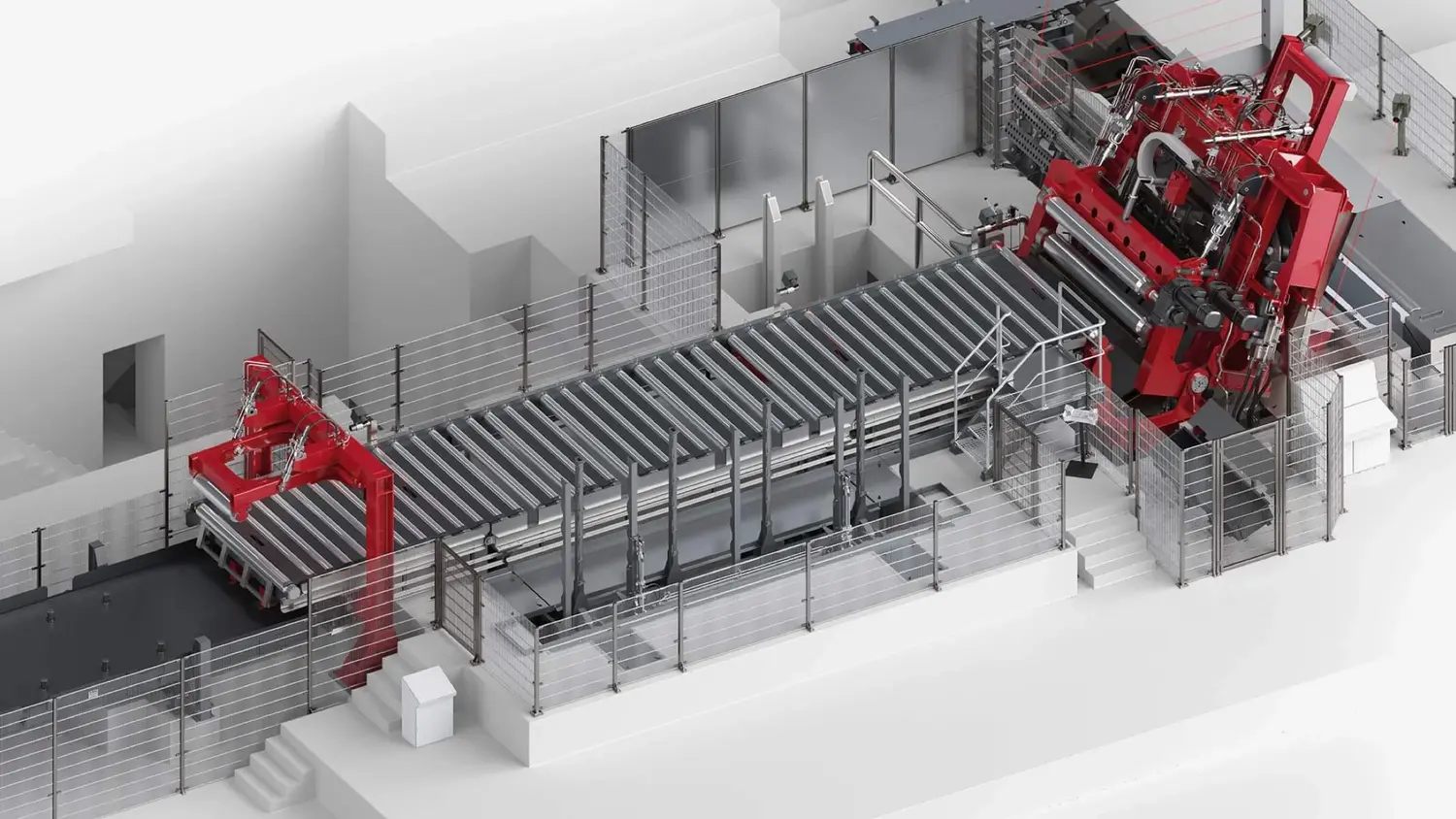

Inspection lines

Focus on material quality

The demands on material quality are constantly increasing, as are the sheet thicknesses and strength values to be treated. For this reason, inspection lines have been a central component of transport systems in hot strip mills for many years. AMOVA offers inline and offline inspection lines for the entire range of normal-strength to ultra-high-strength steel grades. An additional advantage for our customers: With the integrated sample handling equipment material samples can be taken and marked for subsequent laboratory testing to ensure the required quality standards. Whether it is inspection lines for new hot strip mills or modernization measures, AMOVA will always find the optimal solution for you.

![]()

-

Coil packaging lines

Your products are protected from damage and environmental influences

Whether it is hot- or cold-rolled strip, whether galvanised or painted, packaging methods differ according to material, shipment method and destination. What matters most is the careful transport of the coils to avoid damage and thus loss of value. We plan tailor-made systems for you. Depending on the desired level of automation, semi-automatic or fully automatic packaging modules are used and integrated into the transport systems.

The complete automation of the packaging lines including visualization is just as much a part of our service range as the connection of the line control to our customers’ manufacturing control systems and production processes. Of course, we also offer supporting service via remote maintenance.

![]()

-

Slit-coil packaging lines

Gentle and secure packaging of your slit coils

With AMOVA systems, slit coils of different dimensions are safely and efficiently separated, strapped, stacked and packed. Non-contact centering and transport media such as vacuum or magnetic carrier systems ensure gentle handling. Thanks to the modular design, our systems can be perfectly tailored to your special needs – we develop optimum solutions for the desired throughput and degree of automation. Later upgrades are of course possible – the systems can be retrofitted at any time and adapted to changing requirements.

![]()

-

Sheet metal packaging line

Tailored to your needs

AMOVA develops the optimum packaging solution for your requirements. Decades of experience in the packaging sector and a multitude of reliable and efficient systems at customers all over the world make us your competent partner. Whether it’s pure transport routes, systems with automatic and manual work areas or fully automatic complete solutions – our wide range of sheet metal packaging systems also offers the perfect solution for your needs.

We realize diverse packaging systems for a wide variety of product dimensions, which today are produced in modern steel service centers. There are virtually no limits to capacity: The flexibility and throughput rates of our systems easily meet the requirements of large production plants. Thanks to their modular design, the packaging lines can be quickly and easily adapted to spatial and technical conditions.

![]()

-

Strapping machines

Highest sealing strength

AMOVA ensures safety. Depending on requirements, large coils and slit coils are strapped once or several times through the eye and/or on the circumference. Longitudinal or transverse strapping machines are available for metal sheets and sheet packs, with or without feeding of wooden spacers. With a lot of knowledge and experience, we produce reliable and low-maintenance strapping heads with 2-, 4- or 6-point weld seals as well as the corresponding machines for strapping with steel, PP and PET strapping bands.

![]()

-

Marking and labelling systems

Versatile in application

Marking systems: Where geometries or dimensions deviate sharply or if a coil is to be marked at several positions, AMOVA’s 6-axis industrial robots with a large working radius are the ideal solution. For products where marks are applied by linear movement gantry or frame constructions with linear-driven travelling axes are used.

AMOVA supplies complete marking systems from a single source: Marking heads, automation, ink preparation systems, special inks and solvents. Also reading devices for 2D data matrix codes, barcodes and alphanumeric text.Labelling systems: AMOVA develops an individual labelling concept for your requirements. Stuck on or held on by the strap, the label is securely fastened to the product at the place specifed by you.

![]()