The history of oil film bearings

The development of oil film bearings started in the early 1930s. Industry customers were looking for solutions to improve the efficiency and reliability of their rolling mill equipment. The challenge was to develop bearings that can withstand the extreme conditions in rolling mills – high loads, low to high speeds, and extreme temperatures.

Morgan Construction Company in Massachusetts developed the first Morgoil® bearings. Even at that time, mill owners preferred maintenance-friendly components. The Morgoil® bearings guaranteed a longer service life compared to antifriction bearings. The ability to install, repair, and replace them easily increased the cost efficiency of the equipment they were used in.

The invention’s progress caught the eye of rolling mill manufacturer Bernhard Weiss, the CEO of SIEMAG. He soon signed a license agreement for the European market. From then on, rapid rolling speeds and high rolling pressure were no longer a problem.

The introduction of oil film bearings had far-reaching implications for the steel and rolling mill industry. Improvements in the service life and reliability of the bearing components led to a significant reduction in downtimes and maintenance costs. This has enhanced the efficiency of rolling mills worldwide and resulted in higher production capacities.

Technological evolution over 70 years

From 2001 onwards, SMS group has consistently equipped new rolling mills with customized sealing systems and symmetrical backup rolls. To achieve an operationally reliable roll neck design, the engineers built thicker and shorter roll neck ends. The spotlight here was on increasing operational stability and occupational safety, lowering operating costs, and conserving resources.

In 2010, SMS group developed a concept with which these advantages could also be exploited in existing facilities. Working in conjunction with our partners, comprising both customers and roll manufacturers, they were tested in an existing hot strip mill and in an existing tandem cold mill. After careful testing, the experts completely revolutionized the previous design. It promises longer service lives, extremely safe handling, less work in the bearing and roll shop, and a reliable seal. The short, thick contour of the neck absorbs higher axial forces and reduces the weight of the roll.

Around ten years ago, working in collaboration with a seal manufacturer, SMS group designed a high-performance neck seal (HN) as an ideal replacement for the seals that were available on the market up to that point. This HN seal is particularly well known for the high dimensional stability it retains throughout its lifetime. This makes it ideal for use in challenging environments. Another outstanding feature of HN seals is their ability to provide excellent sealing performance. They effectively prevent the ingress of coolant or oil, which helps to reduce maintenance costs and protect the environment.

SMS group subsequently developed a new fastening unit as an alternative to outdated and unsafe types of fastening elements with large ring nuts. The bolt mount (BM) fastening unit guarantees easier, controlled installation and removal of the bearings without having to use a crane or wire rope slings. This not only improves occupational safety with less time required, it is also a cost-effective alternative to hydraulic fasteners.

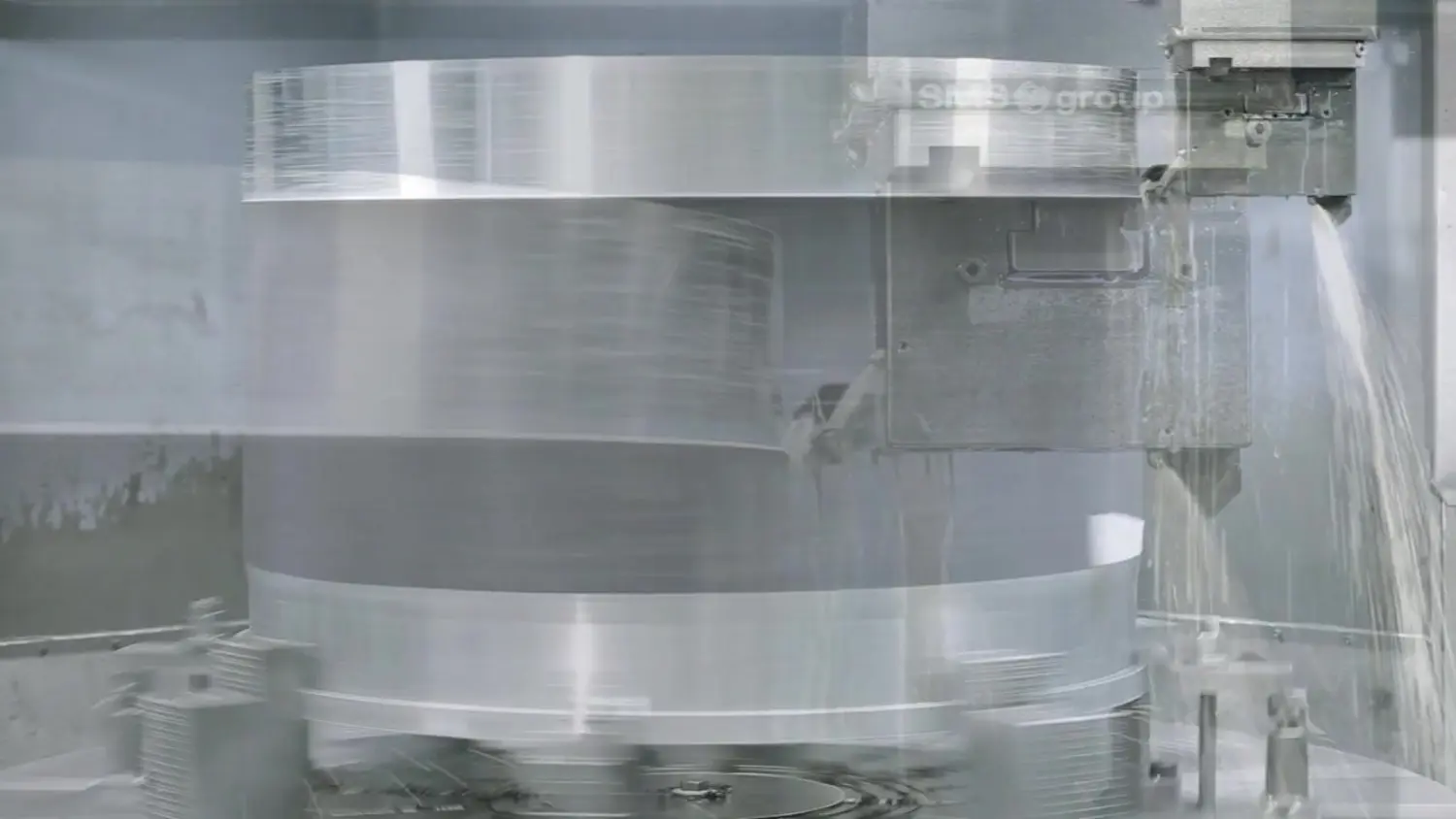

Perfection in precision

In 2016, SMS group designed and built its own test stand for oil film bearings. With this stand, the efficiency and reliability of oil film bearings can be examined under real-world operating conditions. The test stand is equipped with state-of-the-art measuring technology that collects precise data on how the bearings behave and perform. This includes the measurement of lubricant film thicknesses and pressures, temperatures, vibrations, and other relevant variables.

These comprehensive tests allow potential vulnerabilities to be identified and remedied early in the development process. When it comes to developing and optimizing oil film bearings, SMS group’s own test stand is an exceptionally valuable resource. It helps to increase the quality and performance of the products and so meet the needs of customers.

Hydrodynamic oil film bearings are elementary, highly developed components of state-of-the-art rolling mill technology. In a rolling mill, they hold the load-bearing backup rolls and provide a long service life and minimal maintenance under extremely difficult operating conditions. In this way, the oil film bearings play a major role in meeting the high demands for producing the optimal end strip geometry.

The Hilchenbach production site is one of the world’s most up to date. With the development, engineering/design and production teams working side by side, highly efficient processes and close technological exchanges are combined under one roof.

The introduction of the X-Roll® Oil Bearing brand by SMS group in 2016 constitutes a significant advancement in oil film bearing technology. With an array of benefits, these bearings help to improve the efficiency, reliability, and precision of rolling mills. They are an important component of modern rolling technology and assist mill owners in achieving their production targets while at the same time reducing operating costs.

The future of oil film bearings

SMS group continues to be at the forefront of innovation in bearing technology. The result is innovative concepts for advanced oil film bearings. As well as supplying oil film bearings for new plants, the portfolio also includes custom upgrades and an extensive range of X-Roll® Oil Bearing service offerings.

As it looks to the future, the company is focusing on the further development of smart solutions for the entire roll shop, which will enable even more efficient and reliable production processes.

The 70th anniversary of oil film bearing technology is not only a reason to celebrate, but also an incentive to continue to create innovative solutions that support our customers and redefine industry standards. We are proud of our history and look forward to the next 70 years of innovation and excellence at SMS group.