What problems do your customers come to you with?

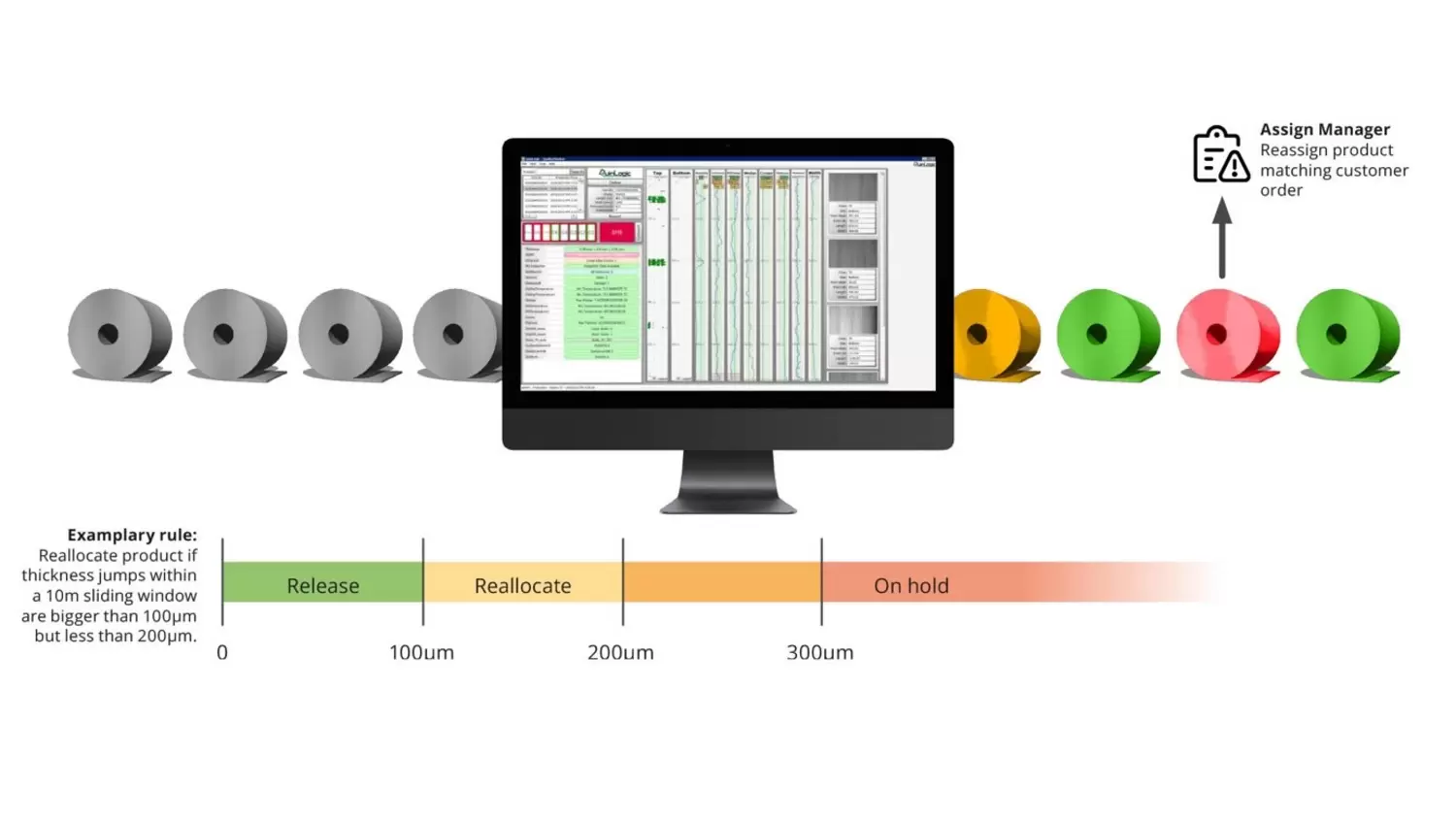

Evers: Even today, quality management is not an automated process in most rolling mills. The plant's personnel have to invest a great deal of time and effort in quality monitoring in order to find root causes for deviations. If there are quality deviations, monitoring personnel must take decisions and, if necessary, action, such as downgrading a coil or, in the worst-case scenario, scrapping it. Customers come to us with a specific problem: they need reliable software for automated coil release, ideally for all process steps. Our software has a market-leading position in the field of quality management. It supports quality managers & experts by automatically releasing coils that have no defects. Consequently, quality managers concentrate on products with deviations. Increased efficiency is obvious. This is exactly what our customers value and why they ask us to extend their existing QES® installations. Their satisfaction is verification of our success.

How does the QES® work exactly? What are its special features?

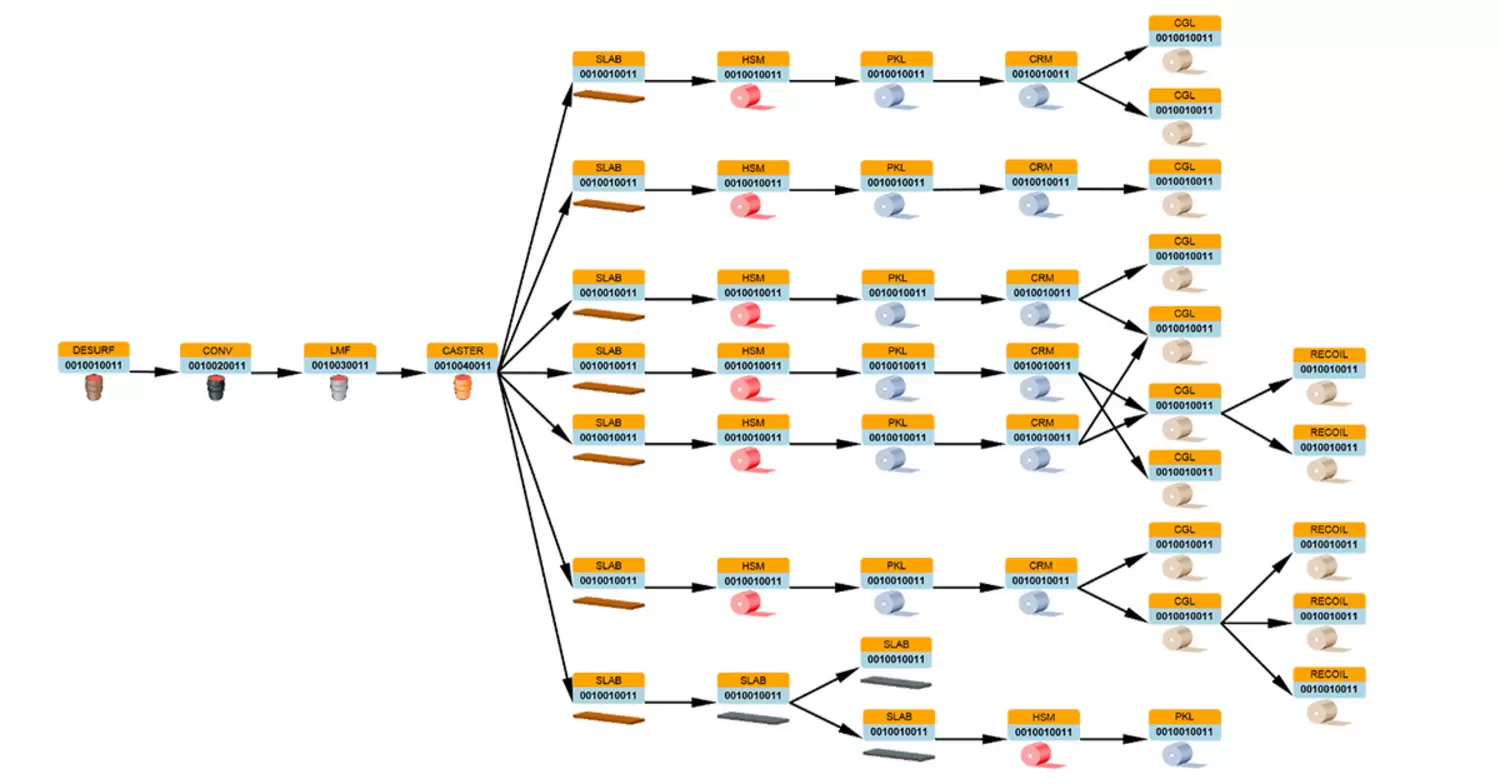

Sarova: It is important for a steel producer to supply coils that precisely meet the customer's quality requirements. To prevent deviations in quality, you have to be able to detect them during the production process already. To this end, the QES® uses comprehensive process, product and quality data from all production stages to grade the quality – from raw material to surface-finished end product. These data are collected and processed centrally in the SMS DataFactory. Available data which were previously hidden or unused are being extracted and analyzed, so that, in step one, the automatic grading of the product quality can be continuously improved and, in step two, a search for root causes can be performed by analyzing correlations.

Findings from these analyses can be translated into new rules, thus making the grading and automatic coil release more precise – 24 hours a day, 7 days a week. If the cause can be attributed to upstream process steps, these can be used to predict faults and defects, ideally at a very early stage of the processing line. The newly induced rules, therefore, help us to learn from mistakes, make the automatic coil grading and release processes more reliable, and produce coils of better quality.

Evers: Typically, release rates of 50% are achieved soon after the start of the project, and this rises steadily by evaluating quality deviations and subsequently specifying rules that are more precise. The LogicDesigner module assists quality experts with the formulation of new rules and optimization of existing rules.

Can customers also identify the specific causes of deviations in this way?

Evers: Yes, that is the goal! Rule-based grading is used to pinpoint quality deviations, and the DataCorrelator analyzes their causes. Every year, QuinLogic holds a user meeting to present new software releases to customers and to collect ideas for further QES® developments. This conference offers important insights: For example, the detailed findings on the correlation between strip tensions and surface defect clusters in a new production line were used to optimize it and ensure a faster run-in. In another example, the combination of several parameters, which were responsible for the formation of cracks, was identified.

In fact, another module plays a crucial role for all data-driven applications here: genealogy. It tracks data related to the coil as well as control results from the liquid phase up to the final product. In other words, data for every single coil can be traced back to its origin. According to customers who use the genealogy feature, the possibility of tracking the process parameters and quality data for a coil from upstream process stages is opening up new ways of optimizing both process and quality.

Sarova: We also know the examples where the "neutralized", fact-based analysis of the cause of the deviation has improved cooperation and exchanges between quality or process managers at the relevant stages of the process. Another effect that should not be underestimated! Proactive quality management is being raised to a completely new level.

How does the QES® communicate with other systems?

Sarova: The data integration, which is associated with every QES® implementation, supports digital connections between the various production stages, sectors, and supply chains, and enables users to improve collaboration, coordination and transparency. To put this in visual terms: The QES® is a kind of "data octopus" that links and evaluates all process and plant data and makes them available to other systems – for example, production planning systems. For instance, the sequence of production orders can be adjusted repeatedly based on the respective quality requirements.

Many plant owners have difficulties with the availability of their data. How does QES® solve this challenge?

Evers: Many rolling mills have very heterogeneous data landscapes and therefore QuinLogic decided beforehand to develop tools like the Data Integration Studio, which supports the connection and unified access to the data. In this case, data remain in the original data sources. Our experts connect the data sources to the QES® and prepare the data for the respective QES® applications. The preparation steps include for example the data aggregation (min, max, avg. mean value etc.) and the data transformation from timestamp into position-based data. This aggregated data is stored on the QES® server.

Some customers extend the QES® by the data management solution SMS DataFactory. The raw data is compressed & stored centrally in the SMS DataDactory. This solution enables not only the storage of raw data but also storage of prepared data ( calculated, time to position converted, aggregated etc.) , meta data and genealogy data for any data driven application in the long term. In addition to this, data cleaning and consistency checks are carried out with this solution.

The available data to be integrated in both cases may come through the ERP system, the process or manufacturing control system, such as MES, or other databases; moreover, data from systems for measuring the width, thickness, flatness, profile, temperature or strip edges, as well as from surface inspection systems, are also integrated.

Can data also be exchanged across plants?

Evers: Yes, it’s possible. Such a solution we implemented at some of our customers. In this way these customers can track and analyze data back to the sister plants.

To what extent do digital applications enable more sustainable production?

Sarova: Intelligent quality management is not only about preventing one or more defective products from being delivered to a customer. Above all, it is about ensuring that these defects do not happen in the first place by detecting and eliminating the conditions that lead to defective production. Predictive systems ensure control of a plant by means of intelligent strategies and use analyses based on machine learning to avoid production problems. This also means that the feedstock can be precisely estimated. As a result, downtimes are reduced significantly, which in turn, saves valuable resources and energy.

The reduction of CO2 emission is another aspect of sustainable production. According to experts , the share of global CO2 emissions attributed to the steel and aluminum industry stands at around 7%. Every year, 4.4 billion tons of CO2 are emitted by steel producing companies. With its intelligent software solutions, SMS is aiming to bring about the transformation to green steel production. The objective here is to make production lines more efficient, make optimal use of equipment, increase product quality, and reduce emissions – and ultimately save energy and valuable resources.

QuinLogic is an established software solutions developer on the market. Why did you decide to operate under the umbrella of SMS group?

Evers: SMS group has more than 150 years of experience in metallurgical plant engineering and extensive process expertise. Combined with digital know-how, we offer our customers plant and equipment, services, and digitalization from a single source. We offer solutions that are used for predicting the condition of plant and equipment and the product quality, as well as for optimal production planning and efficient energy management. With SMS, customers are choosing a full-service provider with which they can fully digitalize their production. Intelligent quality management is an addition to SMS group's digital portfolio and enables us to pool resources and make optimal use of them for our customers – right along the whole production chain.