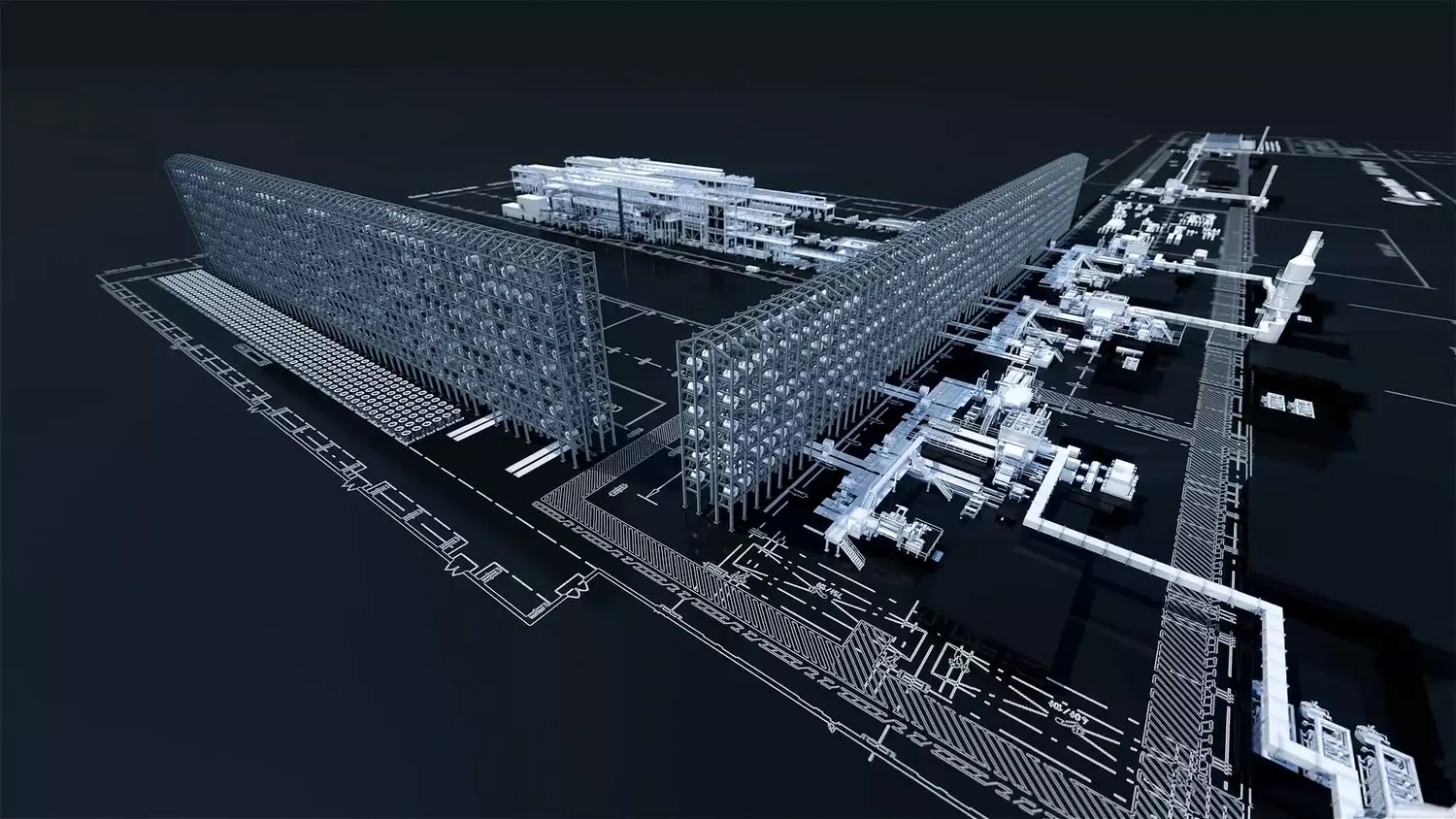

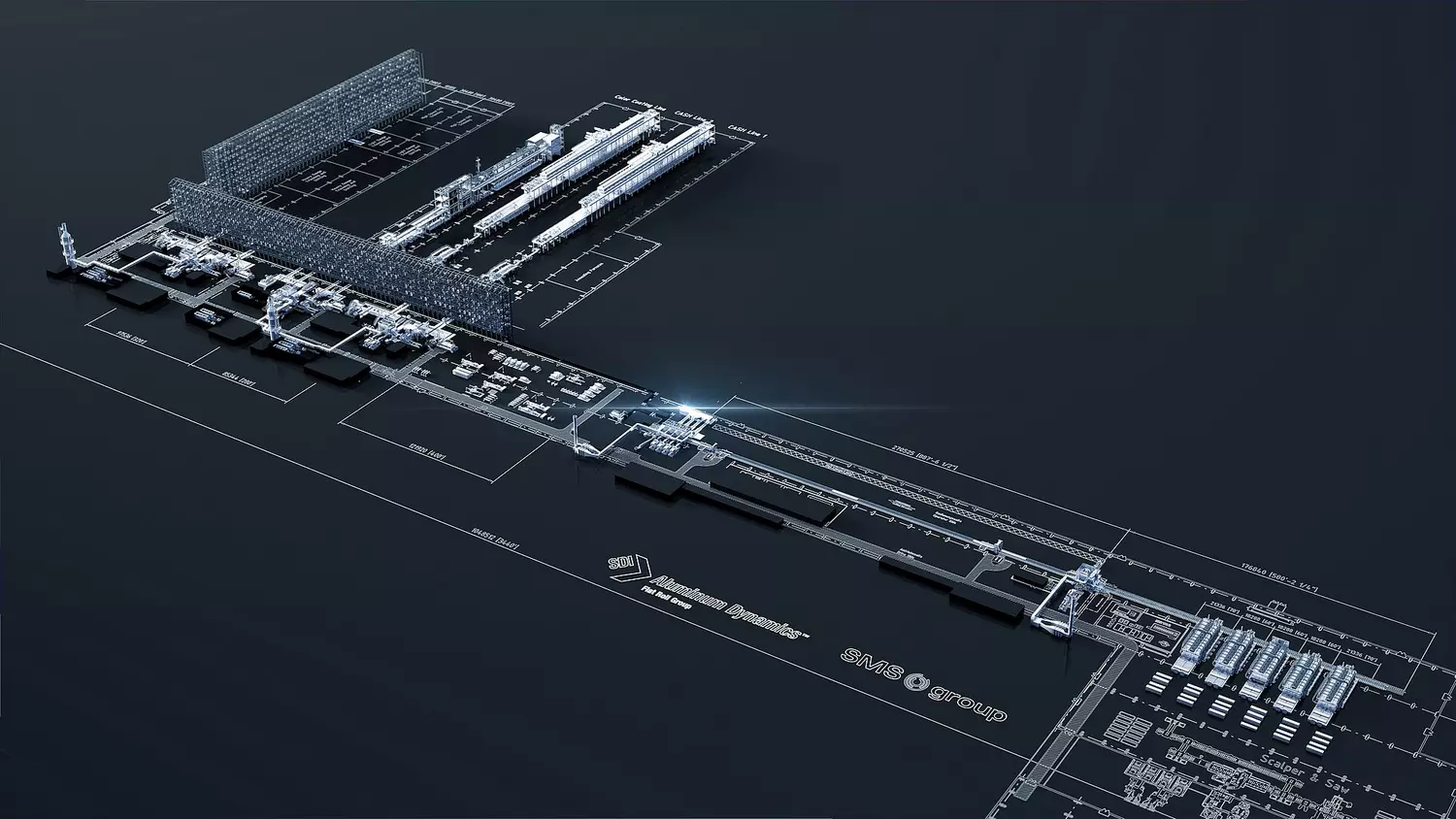

A groundbreaking project is taking shape: Steel Dynamics Inc. is investing in a pioneering aluminum flat rolling facility for Aluminum Dynamics, LLC., a joint venture of Steel Dynamics. Located in Columbus, Mississippi, USA the aluminum flat rolling complex has a planned annual production capacity of 650,000 tons of aluminum sheet for cans, vehicles, and industrial applications. This facility will not only drive technological innovations but also pave the way for sustainable aluminum production.

The project

The Aluminum Dynamics flat rolling mill project marks a significant advancement in the aluminum industry. Led by Steel Dynamics Inc., the state-of-the-art mill in Columbus, Mississippi, USA, will have an annual production capacity of 650,000 tons.

Steel Dynamics Inc. has partnered with SMS Group...

The collaboration with Aluminum Dynamics is more than just another order - it's an exciting journey into the future of the aluminum industry. Together, we are setting standards for the aluminum production for the automotive and beverage can industries through innovative solutions.

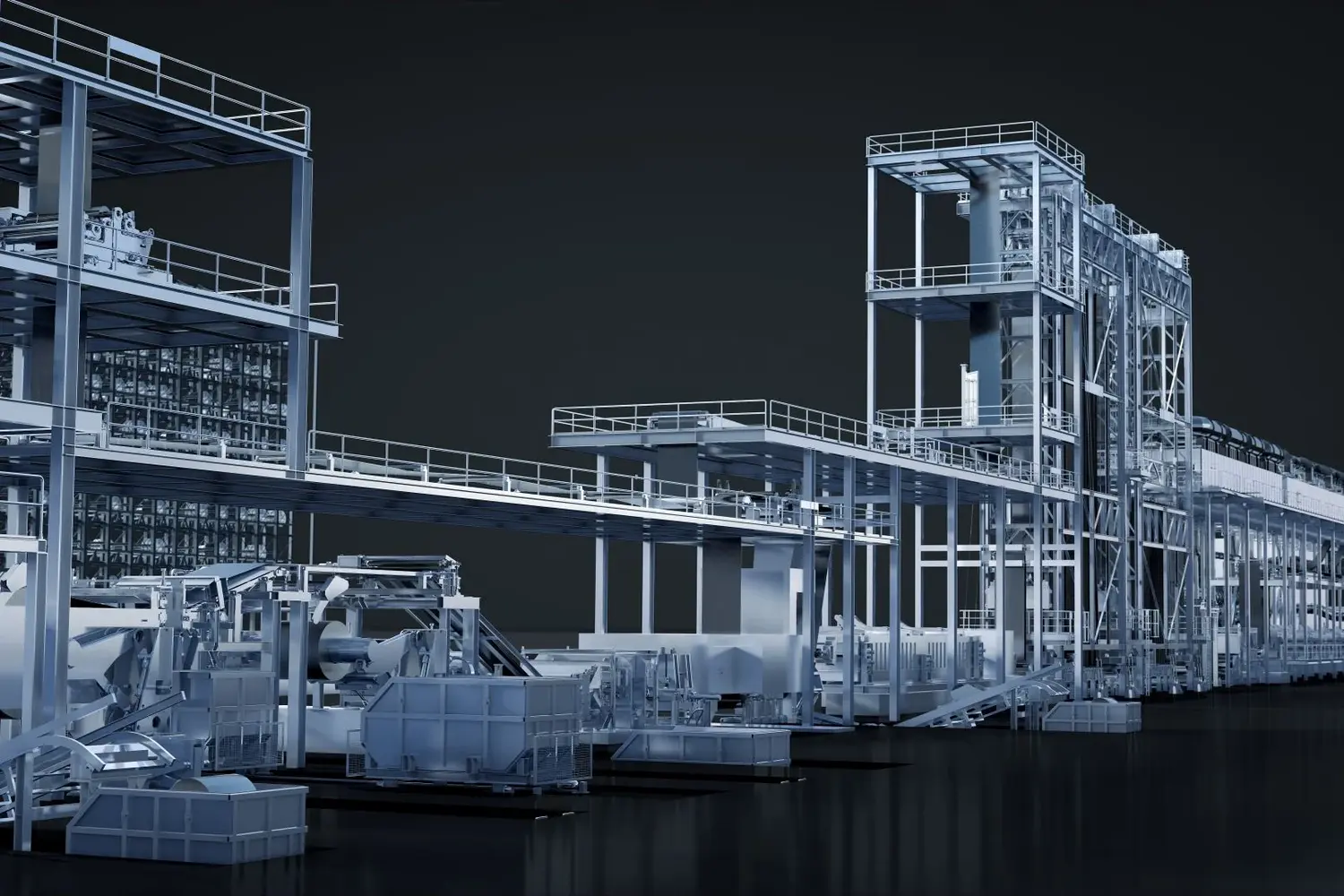

Plant technology

Integrated solutions included in this project

Proven modules of the X-Pact® electrics and automation are one of the cornerstones in the SMS group’s scope of supply for the new flat rolling complex of Aluminum Dynamics LLC in Columbus, Mississippi, USA. They cover the full process chain from power distribution and drive equipment, measuring systems, sensors, and finally all the basic and process automation, including HMI and level 2 setup systems. The state-of-the-art control system with its newly developed software architecture is largely based on modern PLC system hardware and software, e.g. Siemens TIA. The intelligent linking of X-Pact® basic and process automation technologies with integrated technological solutions, such as X-Pact® Hot Start Assistant and X-Pact® Superior Control, opens up a wide range of possibilities for operating entire aluminum flat rolling complex in a highly dynamic and resource-efficient manner with less human intervention.

Like with every SMS project, the new automation system for Aluminum Dynamics, LLC will be fully installed, tested, and optimized during the X-Pact® Plug & Work integration test. Operating personnel from Aluminum Dynamics, LLC will be trained under realistic conditions with real-time process simulations that fully depict the interaction of the plant components and significantly shorten the time required for commissioning and optimization.