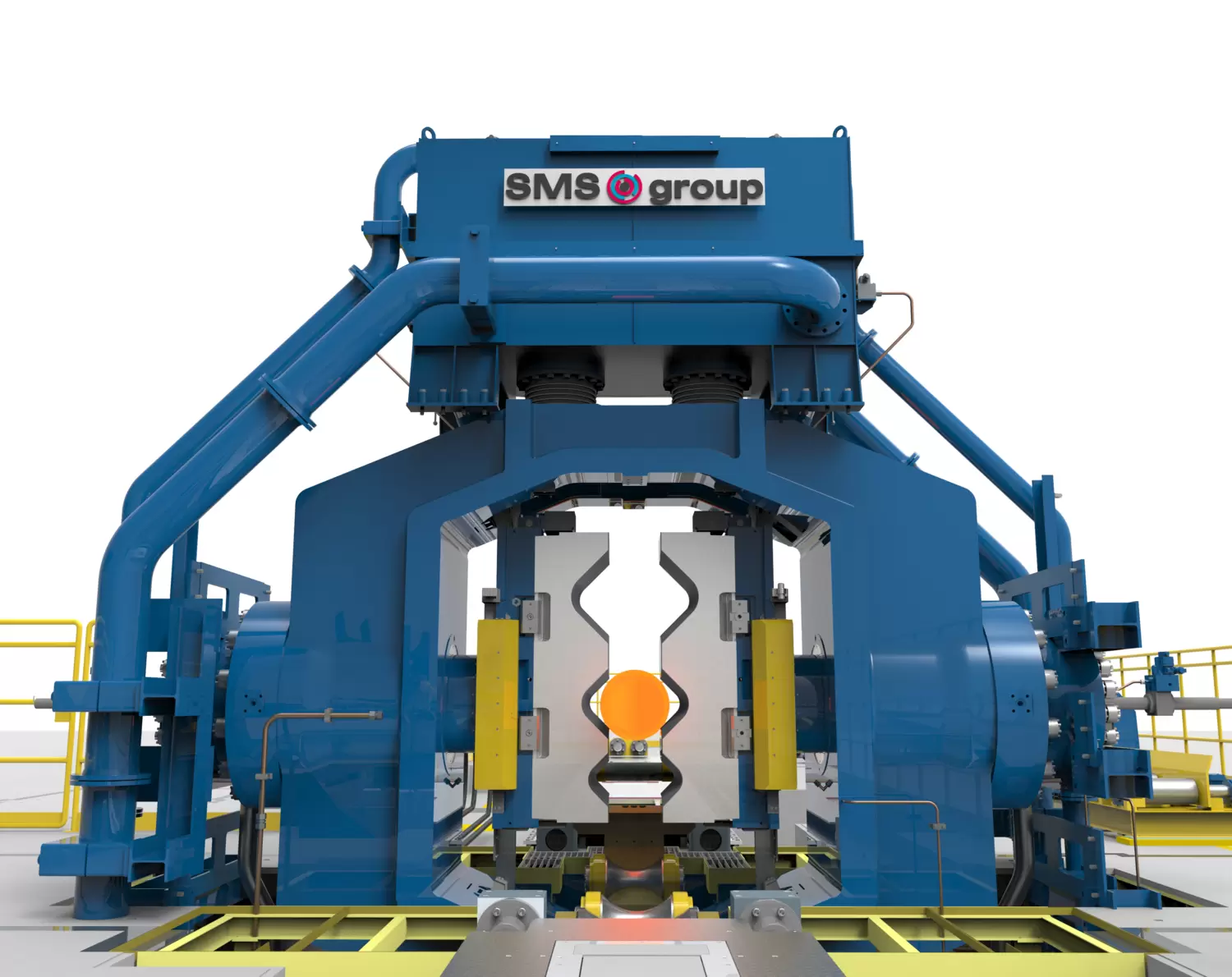

High precision and productivity, perfect microstructure, plus flexible application, batch size, and unit production are the main the demands of the forging industry. This is where our radial forging machines not only meet today’s requirements, but also ensure your competitive edge in the future. What puts our hydraulic radial forging machines at the top of the global tree is this: their innovative design, high performance, and intelligent technology.

-

SMX hydraulic radial forging machines

Integrated plant concept

Main dataSMX hydraulic radial forging machines deliver precision and productivity, perfect microstructure properties, plus flexibility of application, batch size, and single-item production. Central to the radial forging plant is the SMX forging machine. Compared to mechanical machines with eccentric drives, our construction stands out for its clear, simple, and accessible design. The hydraulic drive ensures you can freely and flexibly select all important forging parameters and apply the maximum forging force throughout the entire forging stroke.

-

Horizontal forging machine type SMI

Mass distribution of hot closed-die forgings

Main dataThe horizontal forging machine SMI is an automatically controlled and hydraulically driven 2-ram forging machine with integrated manipulators and centering devices for automatic operation. It is ideal for the mass distribution of hot forgings used for the closed-die forging. It is capable of forging all materials that are normally forged using open-die forging equipment.

![]()

Horizontal forging machine type SMI -

Rail-bound forging manipulator

Main dataOur manipulators for forging machines are particularly robust. They offer you not only high load-bearing capacity, but also precise interaction between the manipulators and the forging machine. That’s crucial for perfect forging results.

The manipulators move in sync with the machine – for a fast and smooth forging process. They come with hydraulically driven tongs. We specially designed the tong peel as a hollow shaft so you can also use a mandrel forging device, e.g. for tubes.

![]()

Rail-bound forging manipulator

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

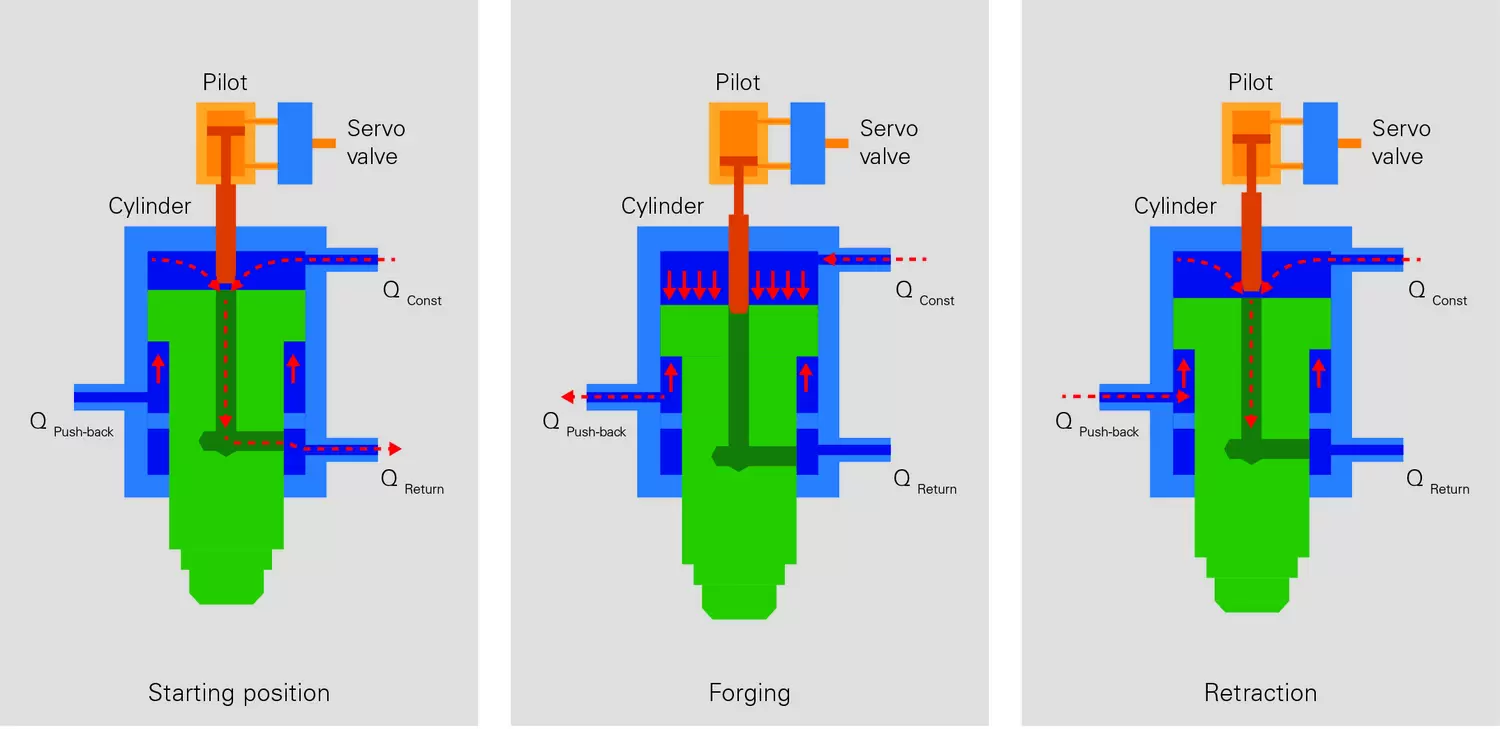

Innovative hydraulic cylinders

Maximum performance with stroke sequences

These virtually maintenance-free press cylinders incorporate our patented technology. Here is the basic principle: a servo-controlled pilot cylinder is followed by the working piston. This pilot cylinder controls the forming rate and return stroke. That means you achieve pinpoint accuracy – every time.

![]()

Hydraulic cylinder Benefits

- Vibration-free operation, low noise

- Up to 300 strokes/min (depending on machine size)

- Extremely long maintenance intervals