High performance cold rolling of advanced steel grades

The production of high quality cold strip in volumes of up to 2.3 million tons per year is a challenge. Perfect for such a production are SMS group tandem cold mills (TCM) - our powerful and at the same time economically efficient flagships in the cold rolling sector. You can operate them in either batch or continuous mode. The arrangement as coupled pickling line tandem cold mill (PL/TCM) in order to establish the production of pickled and colled rolled material in a fully continuous operation in one step is also possible.

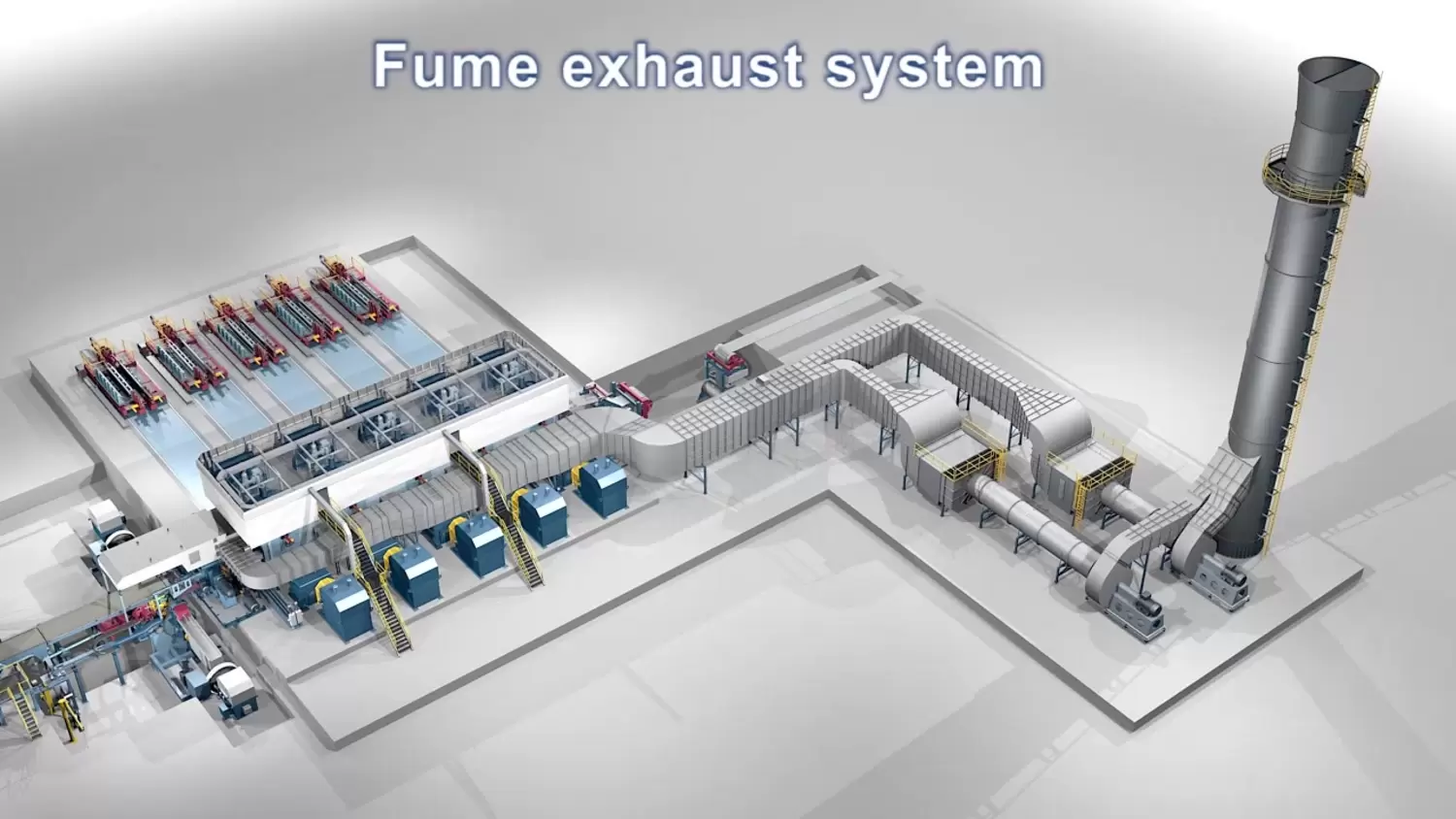

New generation fume exhaust system – World-record in exhaust air purity

Looking at the cold rolling process, we offer various solutions for keeping the process clean and efficient by reducing operating media consumption and emissions and increasing the amount of recycling material. Our latest generation emission control system responds at an early stage and reduces emissions through optimized air flow conditions.

-

Pickling Line Tandem Cold Mill (PL/TCM)

Integrated pickling and rolling process for high capacity

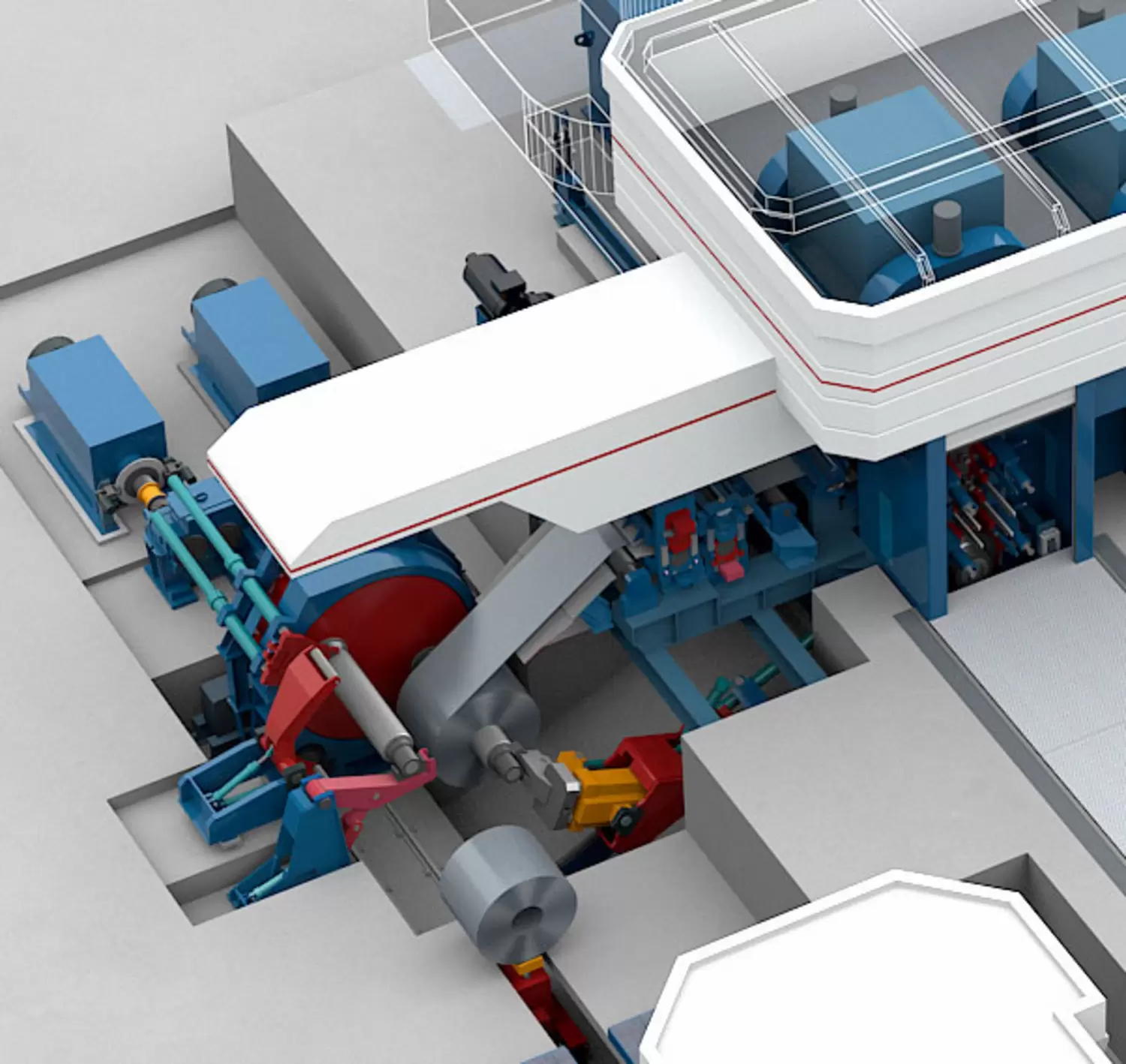

Main dataCentral to the PL/TCM is the direct coupling of pickling and rolling. This ensures a continuous production flow. The main units on the entry side are: a pay-off reel, laser welding machine, tension leveler, turbulence pickling line, and several horizontal strip accumulators. Next in line is the mill section consisting of several mill stands in CVC® plus design and a continuous exit section with drum shear, double or carousel reel, and, for the most applications, the inspection unit "Rotary Inspect" in either inline or offline arrangement.

![]()

Layout of PL/TCM -

Continuous tandem cold mill (CTCM)

Continuous rolling process

Main dataCrucial for large production volumes is a continuous production flow. Further benefits are smooth production flow, reduced roll wear, high yield, and consistent, reproducible product quality. What defines the continuous tandem mill (CTCM) is a continuous entry section featuring a pay-off unit, welding machine, and strip accumulator. All this is necessary to ensure an uninterrupted production flow. Typical exit-side installations are also here the drum shear, as well as a double or carousel reel and the inspection unit "Rotary Inspect".

![]()

-

Batch tandem cold mill (BTCM)

Designed for high flexibility

Main dataEspecially in Europe, America, and Russia, there are many batch TCM in operation. That's no surprise, because this mill type offers considerable advantages and makes production planning flexible. One limitation is the coil changing and strip feeding time. To increase the yield of such lines, we have developed a number of trend-setting technical features in recent years. Needless to say, we can easily retrofit all our newly developed features.

![]()

-

Multipurpose mill CVC® plus M 18/4

Flexible production of soft and high-strength materials on one mill

It's a huge challenge to produce smaller batches profitably, especially when not running the mill at full capacity. Our new CVC® plus M 18/4 stand for reversing and tandem mills is a multipurpose mill that covers a very wide product range from soft IF-grades (Interstitial Free) right through to HSS (High Strength Steel) and stainless steels.

We install the CVC® plus M 18/4 multi-function stand type in both new and existing mills. Central to this equipment is a rapid and easy-change roll set in CVC plus 4-high and 18-HS design. That ensures you can expand your product range at low cost.

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Superior mill stand design and advanced actuators

Efficient rolling process - top product quality

FeaturesOutstanding CVC® plus 4-high and CVC® plus 6-high designs for better yield and quality, proven by more than 800 installed systems.

![]()

Mill stand actuators Benefits

- Shifting under all load conditions

- The largest roll gap adjusting area for flexible handling of a wide variety of incoming hot strip profiles

- Top flatness results

- Excellent strip quality due to uniform load and roughness transfer

- Lower operational costs with less roll wear and less maintenance

-

Revolving mandrel support bearing

Improved carousel reel design

The demand for cold strip in high and highest strength grades will continue to increase. Part of the plant, which is subject to a special load, is the tension reel in the exit section of a cold rolling mill, which is in a continuously operating tandem cold mill often designed as a carousel reel. Until today, when winding high-strength strips under high tension, there were certain limitations due to the unsupported mandrel during turning from starting into the final winding position. We developed a revolving mandrel support bearing, which is supporting the mandrel at all times during coiling. Thus, any restrictions are eliminated.

![]()

Design concept of carousel reel mandrel support bearing Benefits

- Reel mandrel supported in any position

- High tensions even at initial windings

- Higher reductions and improved flatness even at the strip head end

- Ideal solution for coiling of relatively thinner material, due to easier strip guiding

- Clear, simple and rigid mechanical design

- Fewer mandrel spare parts required

- Lower operating and maintenance costs

-

New roll changing concept

Fast and safe roll change

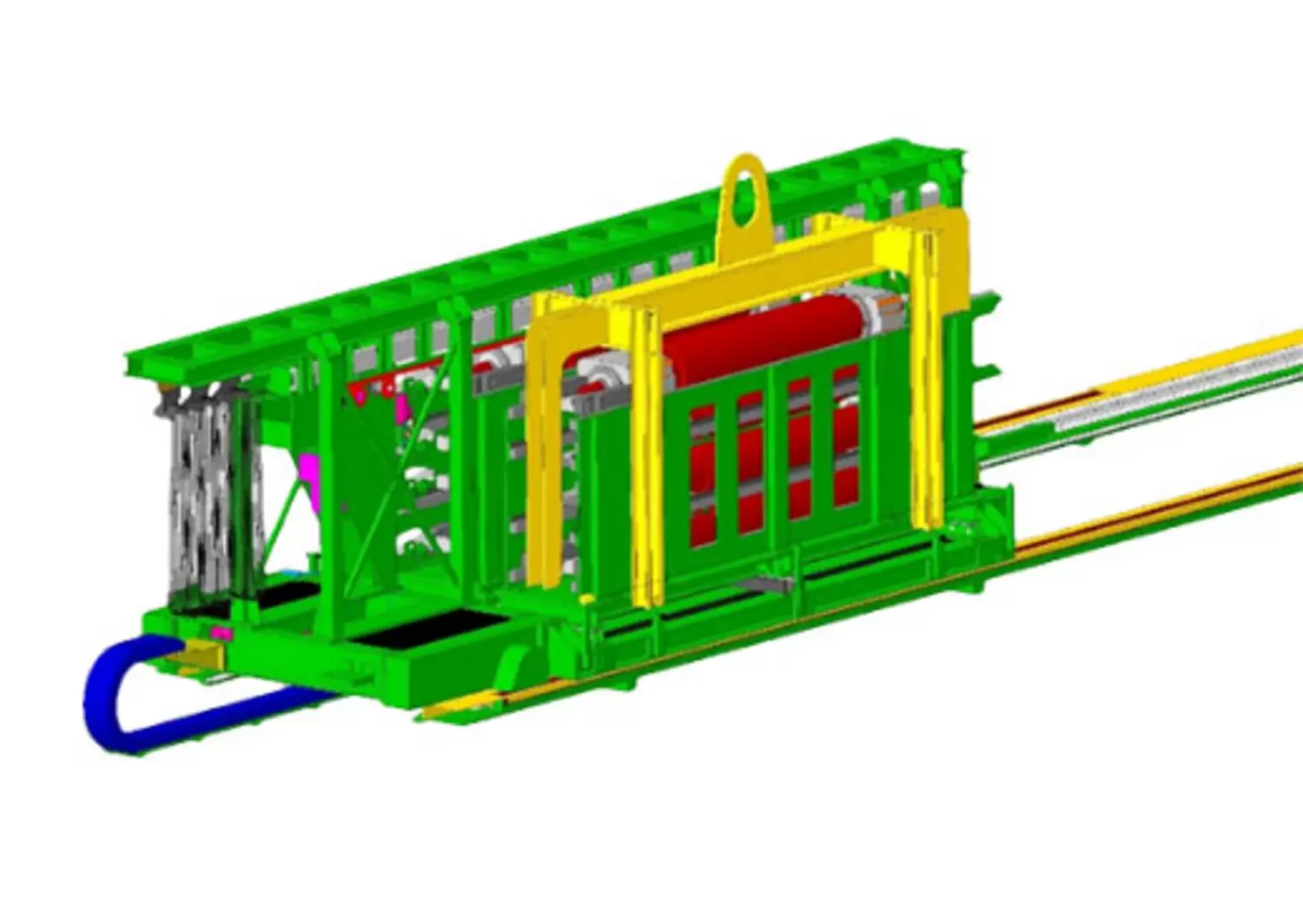

In rolling operation, it is important to keep non-productive and set-up down times as short as possible. An important topic in this context is the fully automatic roll change. SMS group has modified the procedure in a way that the roll changing car can be loaded fully automatically. A complete set of work rolls for the 4-high mill stand and/or a set of work rolls and intermediate rolls for a 6-high stand are placed in a transport cartridge, which can be deposit on the roll change car.

![]()

Concept image of the new roll change car Benefits

- Fully-automatic operation possible

- Less crane activities needed

- Less manual actions necessary leading to higher safety

- Fewer operators required

- Fast roll change results in short stand-by times

-

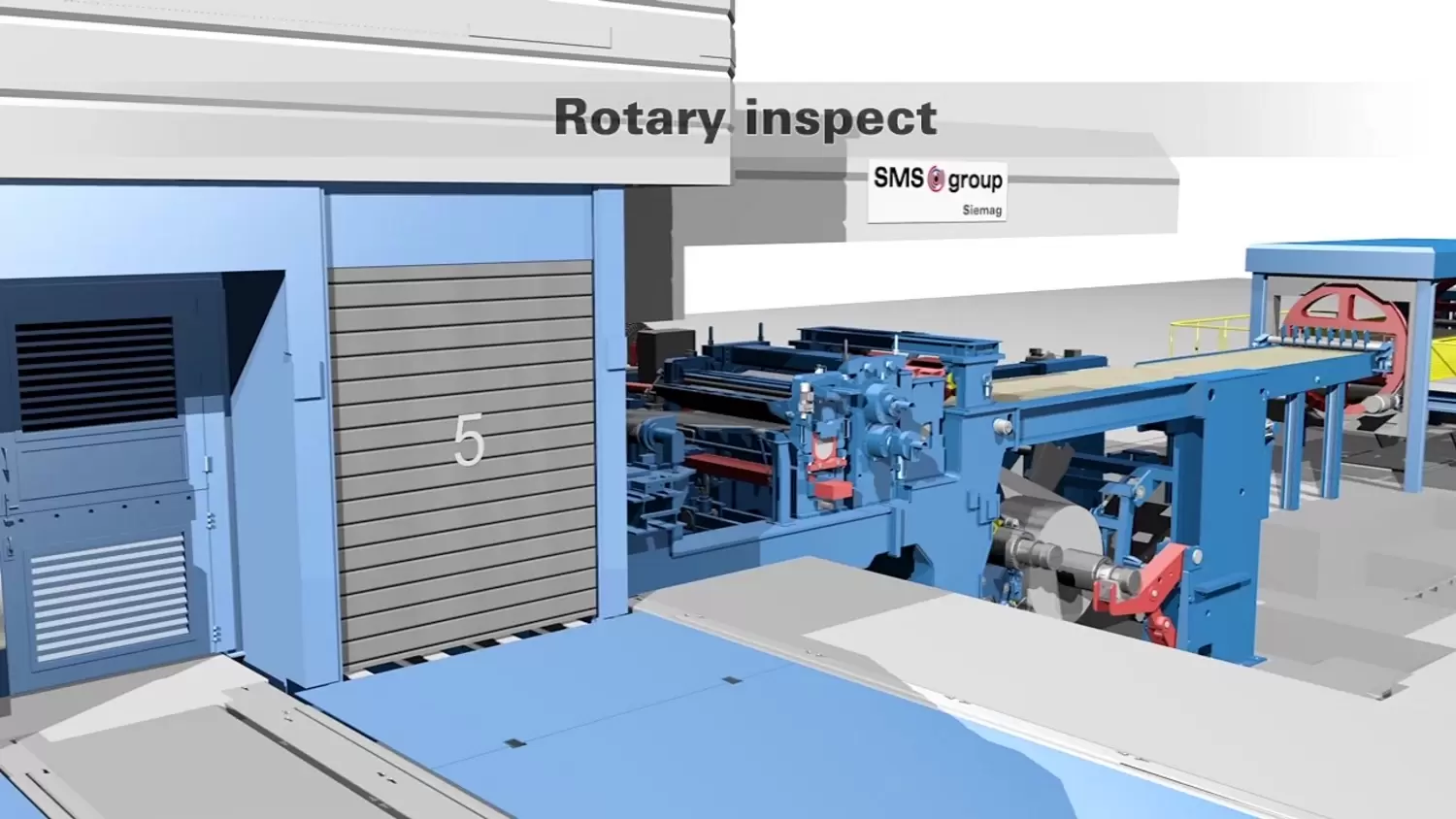

Rotary Inspect

Fast and reliable strip inspection

FeaturesEfficient production on a high quality level today requires also efficient methods in quality control. Our patented inspection Rotary Inspect for inline and offline application sets a record for safety and ergonomic design as well as efficiency in manual assessment of strip top and bottom side. As inline inspection station, Rotary inspect is installed immediately behind the carousel reel or double tension reel.

Benefits

- Ergonomically, safe and reliable inspection

- Efficient manual assessment of both strip surfaces

- High inspection frequency

-

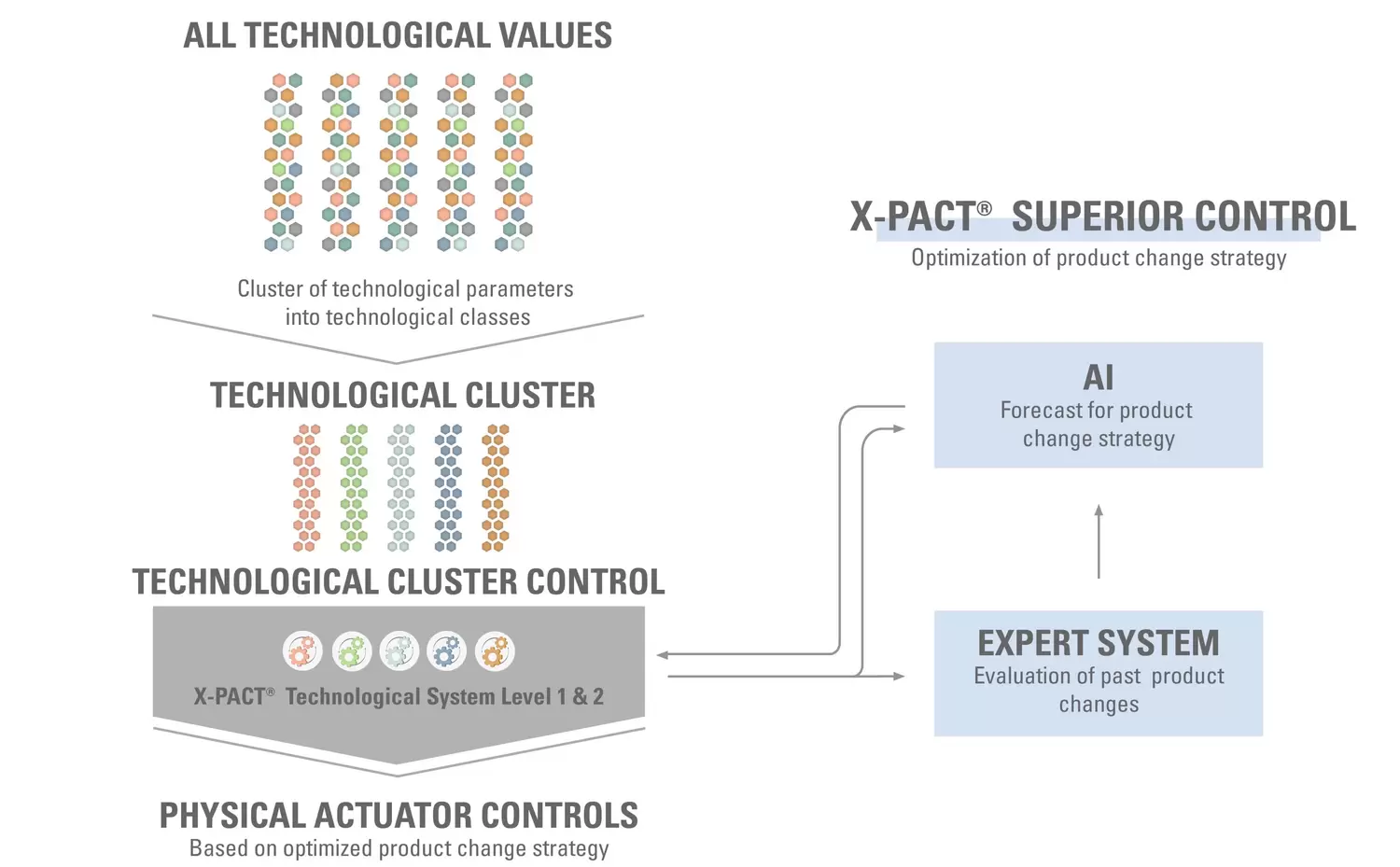

X-Pact® Superior Control

Expert system for selection of optimal product change strategies

As an integrated technological solution that comprises artificial intelligence and expert systems, X-Pact® Superior Control actively supplies superordinate product change strategy presets to the level 1 and level 2 automation systems. The learning algorithms ensure a continually self-improving of all strip quality parameters and operator independent control by automatic solving of critical process situations.

On the way to the Learning Rolling Mill, the following of our intelligent OT solutions still play a crucial role:

- X-Pact® Hot Start Assistant ensures a fully automatic rolling start under challenging condition

- X-Pact® Profile Distribution Optimizer allows an automatic, online flatness set point correction

![]()

-

Process control

X-Pact® automation solutions for tandem cold rolling mills

X-Pact® for cold rolling mills pools our special process know-how in a system oriented toward the distinct cold rolling process technology required here. Our leading automation expertise in combination with experience and expert knowledge form the perfect basis for the digital solutions.

![]()

-

New generation fume exhaust system

World-record in exhaust air purity

Looking at the cold rolling process, we offer various solutions for keeping the process clean and efficient by reducing operating media consumption and emissions and increasing the amount of recycling material. Our latest generation emission control system responds at an early stage and reduces emissions through optimized air flow conditions.

Benefits

- Optimized arrangement of equipment: Housing, suction hoods, ducts, fans and filter units

- Separation and conduction of the exhaust air by emission quantity / ratio

- Reduced exhaust flow in the interstand area

- Fulfilment of strictest environmental demands

- Saving of energy costs due to reduced exhaust air flow

-

X-Roll® laser welder

Fast, safe, and successful welding of challenging steel grades

The X-Roll® laser welder is designed to join hard-to-weld strip material. The laser welder comes with a patented, inductive heat treatment system including automatic welding parameter calculation system, a quality assurance system, and an exchangeable laser source. The laser welder has been installed in new plants as well as in modernization projects.

The X-Roll® laser welder will be controlled by X-Pact® automation. The control system is designed as a package unit with its own basic automation and X-Pact® Vision HMI system.

![]()

Laser welder