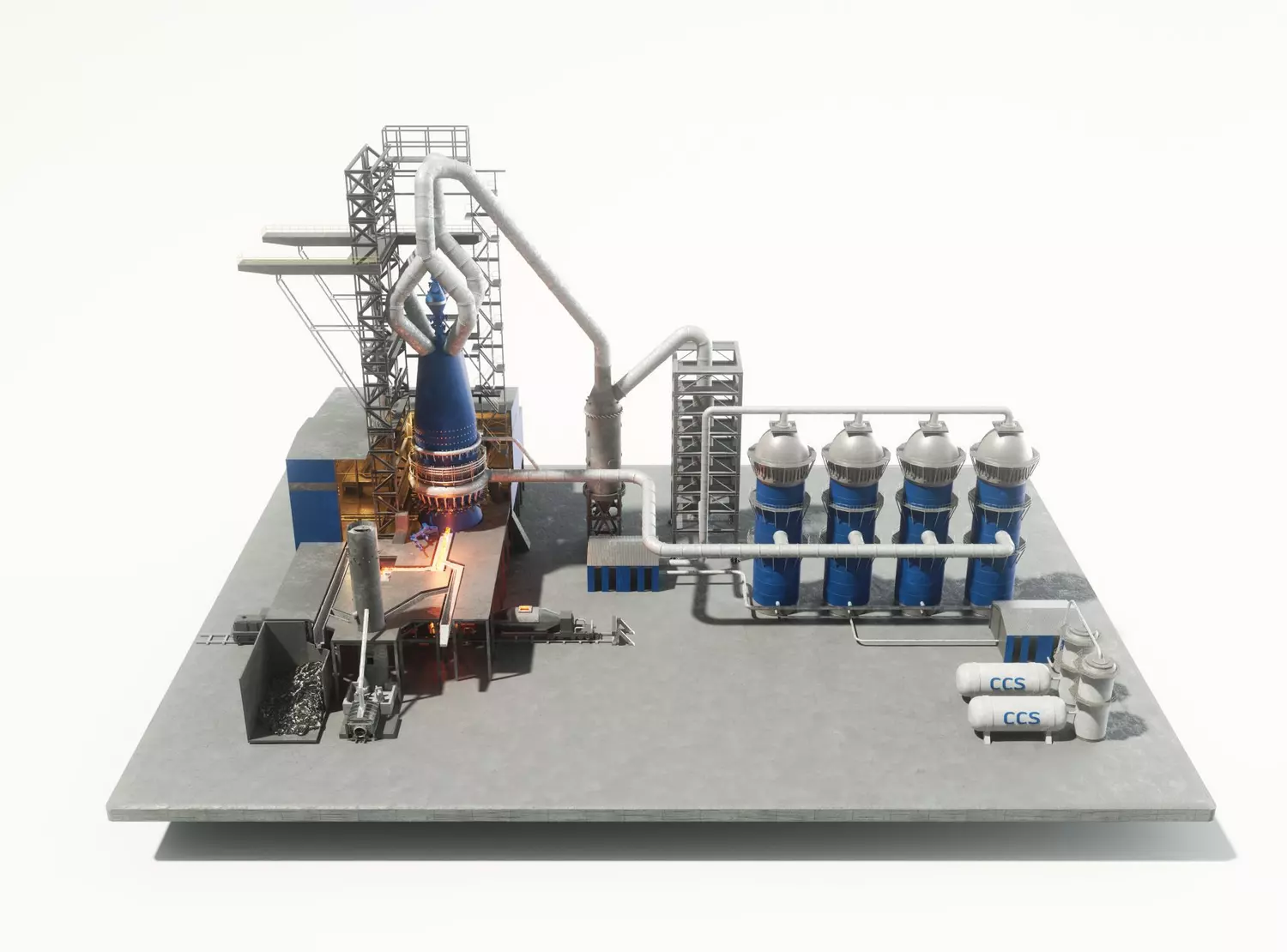

Decarbonizing primary steelmaking is a critical endeavor for the industry's sustainability, with the current focus primarily on H2 direct reduction plant (H2-DRP) technology. To address the limitations and challenges of the DR route, SMS group developed the Paul Wurth EASyMelt technology.

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Electrically assisted syngas smelter

The Paul Wurth EASyMelt is a resource-flexible, crisis-resiliant and cost-efficient alternative to direct reduction shaft furnaces. It offers much lower investment and operational costs compared to conventional direct reduction plants. Plus, it can be integrated into existing integrated steel plants, demonstrating a significant pathway for the decarbonization of existing blast furnaces worldwide.

![]()

-

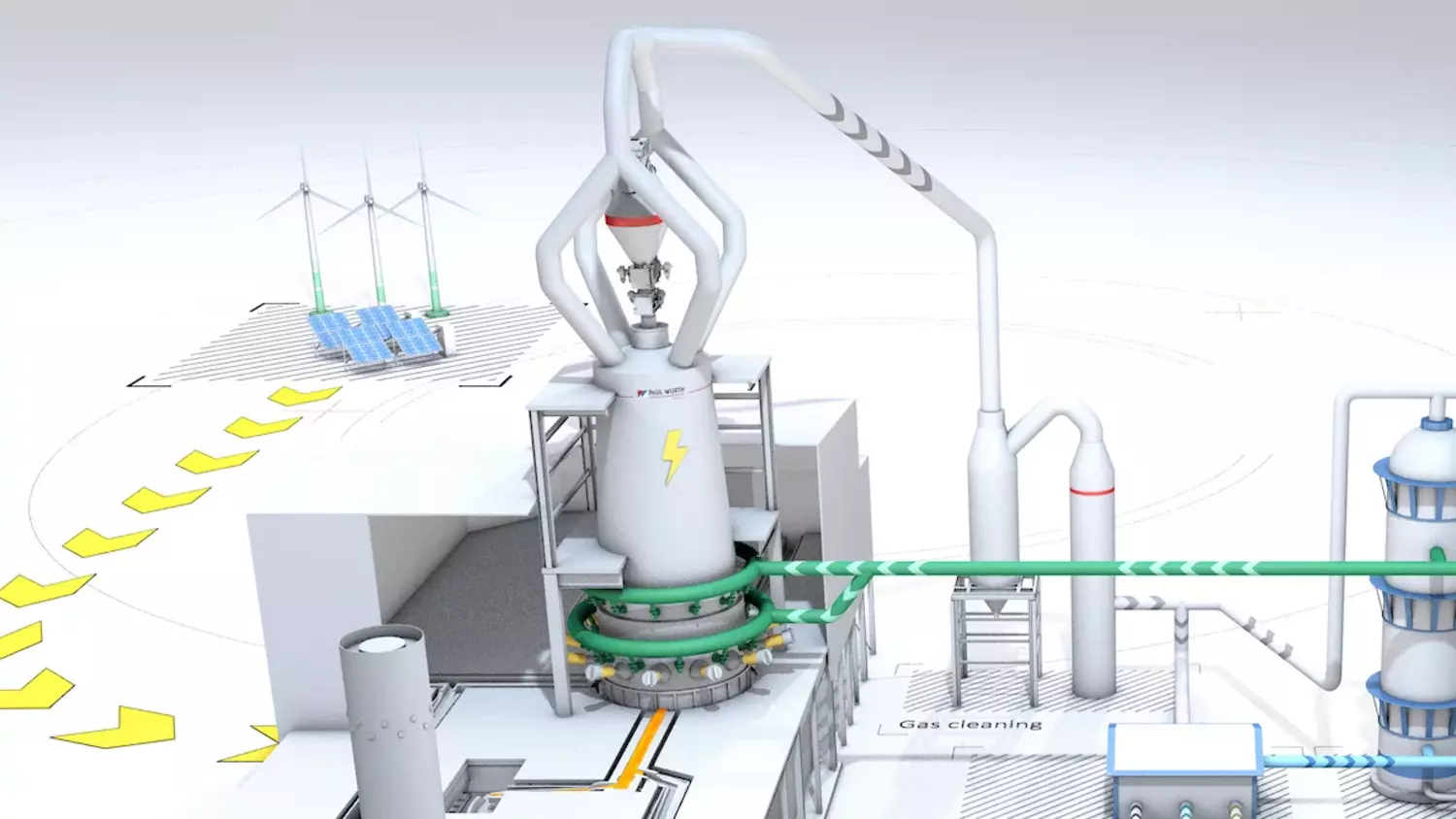

Injection of reducing gas via shaft

The initial phase involves the injection of syngas (reducing gas) at 950°C into the existing blast furnace at shaft level, creating the conditions for iron ore direct reduction. This syngas can be generated through optimized methods such as SMS group’s novel dry reforming syngas stoves.

![]()

-

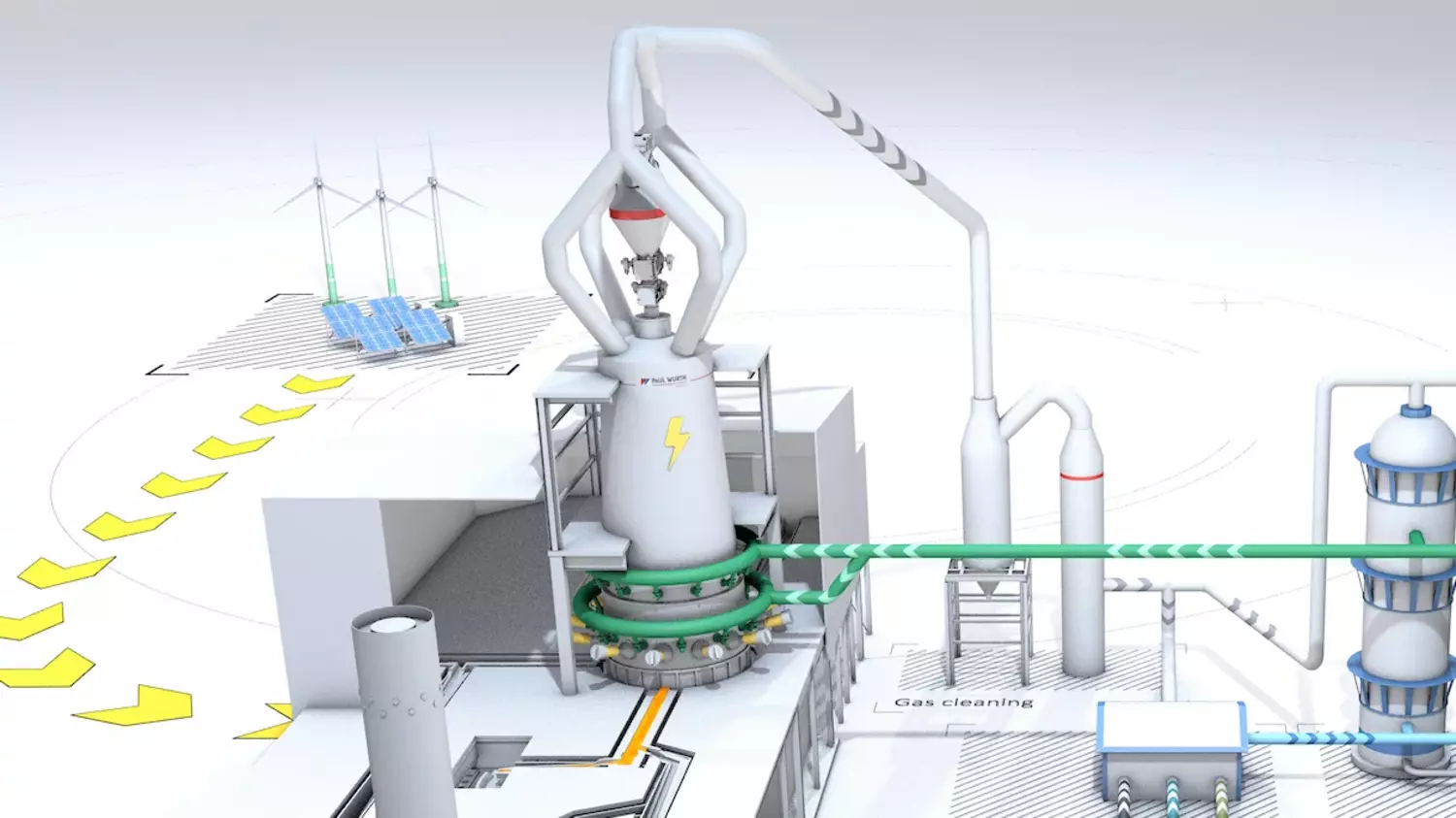

Production of reducing gas

The syngas stoves produce syngas (H2 + CO) from methane and CO2, using a non-catalytic dry reforming reaction in a cyclic operation. Dry reforming allows for internal CO2 recycling in the EASyMelt system, by chemically upgrading CO2 to CO with the help of methane from coke oven gas or natural gas.

![]()

-

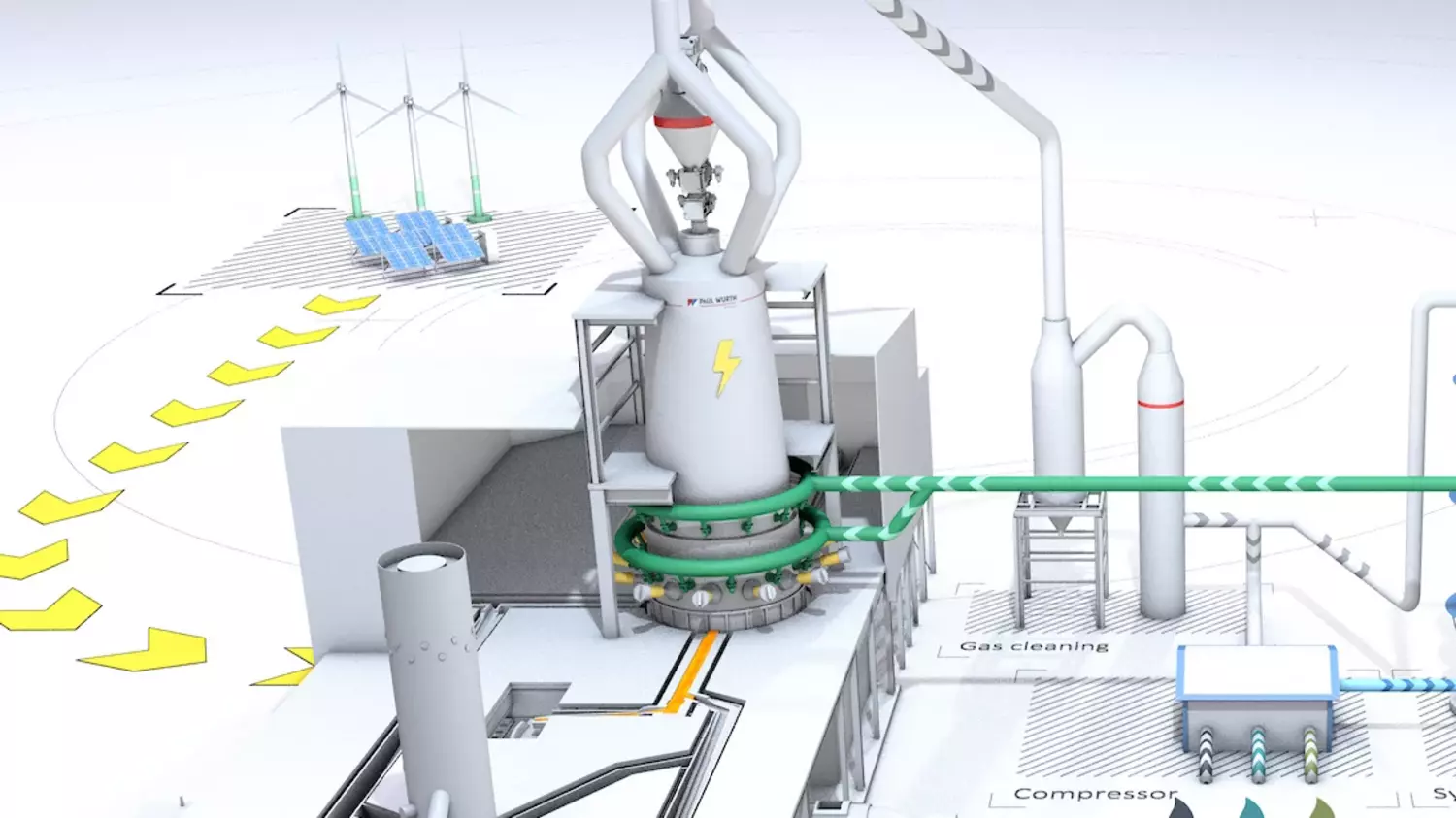

Injection of reducing gas via tuyeres

Syngas is introduced at the tuyere level. This innovative approach diverges from traditional methods, offering technical ingenuity and flexibility to incorporate hydrogen into the reducing gas composition. Hydrogen utilization is highly efficient in this context, as the very high temperatures obtained through high temperature syngas production technology allow for a large percentage of the hydrogen to reduce iron ore very quickly.

![]()

-

Plasma-based tuyere level superheating

A plasma-based superheating system is implemented at the tuyere level, effectively elevating the syngas to temperatures between 1,700°C to 2,200°C. This electrifies the ironmaking process and has undergone successful previous trials.

![]()

-

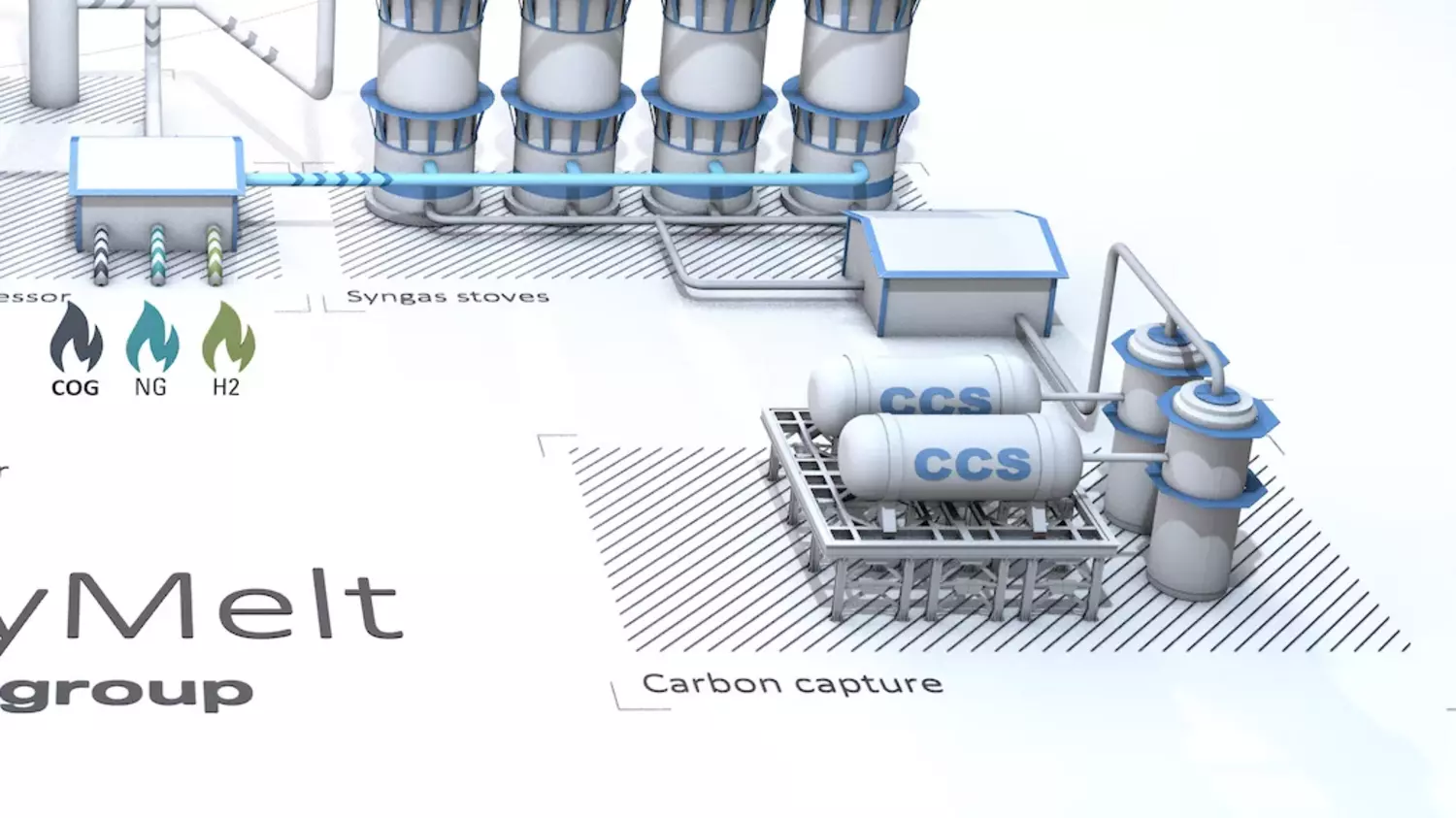

Carbon capture integration

The final phase revolves around carbon capture. Any remaining emissions are systematically captured for storage or utilization, ensuring complete climate neutrality. A notable synergy arises from the enriched CO2 stream produced by the syngas dry reformers, aligning seamlessly with carbon capture objectives. Additionally, processes like sorption-enhanced water gas shift (SEWGS) are viable options for decarbonizing the residual top gas.

![]()