Heating and cooling technologies are of course of prime importance for strip processing as the metallurgical properties are set with a combination of precise heating and cooling curves.

-

Heating technology

Heating technologies are of course of prime importance for a furnace manufacturer. Drever furnace technology is based on a wide experience in the heating technologies for more than 50 years.

![]()

-

Direct flame

In direct flame furnaces the flame created by the combustion of natural gas radiates freely in the furnace. The fumes travel in counter flow with the strip to allow a preheating of the strip before the heating section. At the entry of the preheating section, the fumes are collected and sent to a global recuperator to preheat the combustion air used by the burners.

This technology allows fast reaction of the furnace and high efficiency thanks to the combination of high combustion air temperature and a preheating section.

When it is necessary to avoid the oxidation of the strip in the furnace, the combustion is under-stoichiometric, so the furnace atmosphere is reducing. The residue of the combustion contains therefore unburnt radicals (mainly hydrogen and carbon monoxide) that are burnt in the post-combustion taking place in the preheating section.

For the heating of stainless steels, there is no risk of strip oxidation so the combustion can be achieved directly with an excess of oxygen (oxidizing atmosphere).

-

Radiant tube

In radiant tubes furnaces the combustion of the gas takes place within a tube, so there is no contact between the strip and the fumes. The fuel can be natural gas, but also coke oven gas, blast furnace gas or a mixture of different gas.

Radiant tubes must be used in a protective atmosphere furnace of HNx, a mixture of nitrogen and hydrogen. There are several shapes: I, P, double P and W. I, P and double P are used together with recuperative or regenerative burners while W shapes are only available with a high performance recuperator. These tubes can be made of cast steel, welded steel sheets or, for I tubes, ceramic material.

-

Combustion technology

The combustion of gas generates mainly 2 pollutants: CO2 and NOx.

- The energy consumption and thus the quantity of CO2 generated can be reduced by recovering the heat in the fumes and preheating the combustion air thanks to a central recuperator, individual regenerators or individual recuperators. The remaining heat in the fumes can be used to produce steam or hot water in waste heat boilers.

- NOx production can be reduced with specific combustion technologies aiming at reducing the maximum flame temperature and / or the level of oxygen within the flame. Fumes can be also treated by De-Nox system including some catalysts before release in the atmosphere.

-

Induction

For high heating rates, induction heating system is the right choice. A rapidly alternating magnetic field is generated by an induction coil. As a result of the variations of the magnetic field, electric currents called Eddy currents are generated inside the strip. The electrical resistance against these Eddy currents generates heat directly inside the strip (Joule heating). Thus the strip can be heated very rapidly.

Two kinds of systems are proposed:

- Longitudinal flux is very efficient for ferromagnetic strip, which is the case for carbon steel, silicon steel and ferritic stainless steel below the Curie temperature

- Transversal flux is used when the strip is not ferromagnetic, which is the case for carbon steel and silicon steel above the Curie temperature, and for austenitic stainless steel.

-

Electrical heating systems

Electrical heating elements can be installed in radiant tubes or directly in the furnace. They can be made of: FeCrAl, NiCr or Molybdenum. The selection of the material to be used depends on several criteria such as furnace temperature, atmosphere and dew point.

-

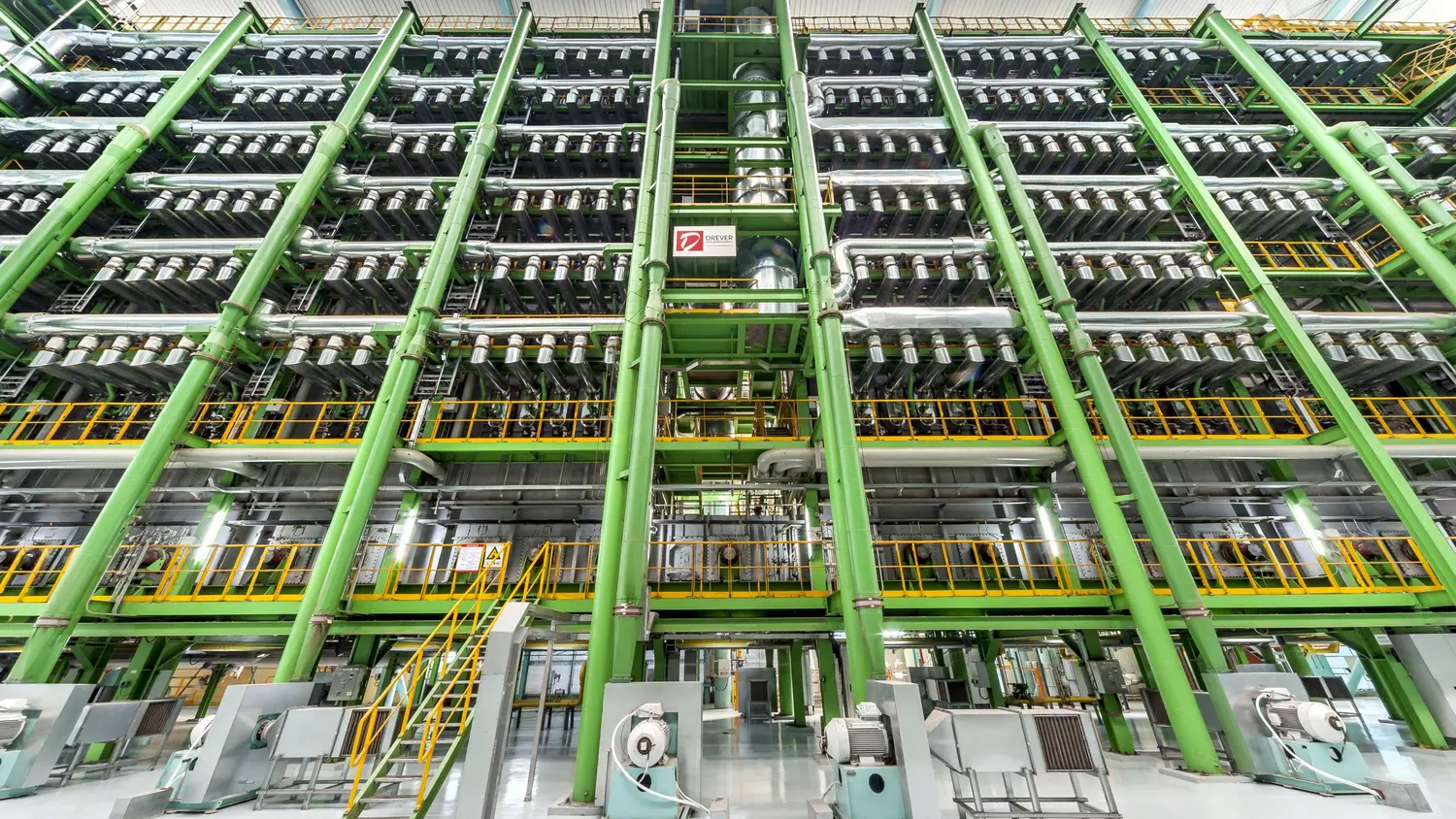

Heating technologies are of course of prime importance for a furnace manufacturer, but the metallurgists need very precise cooling rates to reach the desired microstructure, and thus the in-use properties of the steel. Moreover, a uniform cooling is necessary to obtain a good flatness of the product. Drever cooling technology is based on extensive research to improve the uniformity and adjust the cooling rate, therefore increasing the quality of the strip.

![]()

-

Cooling tubes

Tubes cooled by cold air are introduced into the furnace. These tubes can be straight, or have a « lyra » shape depending of the requested cooling rate.

They are used when the cooling rate must be very low, like for some heat treatment of thin strips for tin plate, or for the slow cooling requested by silicon steels. -

Cooling slots and jet cooling

A fan blows either atmosphere gas or air to the surface of the strip. This can be achieved through a plenum, or simply with slotted tubes when the distance between the slots is high.

The method is widely used:

- with HNx for the slow cooling / fast cooling inside the furnace

- with air to cool down the metallic coating in the after pot cooling, or for stainless steels.

-

Ultra-fast cooling

Drever International is specialized in the construction of ultra-fast cooling with HNx. Very efficient seals and a perfect control of the pressure inside the furnace allow the injection of up to 50% hydrogen in the HNx.

-

Water cooling

Water is sprayed onto the strip in order to cool it down for further process. It is important to achieve a minimum cooling rate in order to block carbide precipitation in the material. Especially for thick strip this is not possible by air cooling.

To achieve good flatness values a uniform cooling is necessary. Drever International has carried out extensive research to improve the uniformity of the cooling and therefore increase the quality of the strip.

-

Air cooling

Air cooling is used to reduce the temperature of the strip smoothly. The air is blown through the plenum and nozzles onto the strip with a high velocity to increase the convection.

The flatness value of the strip is better with air-cooling than with water-cooling. It is used where a good flatness of the strip is paramount.

-

Mist cooling

In this kind of mist cooling sections mist is blown on the strip. The mist consists of air and water. Cooling rates are between typical values of an air quench and a water quench. By intelligent control the mist cooling section can operate within a wide range of different cooling rates.

It is used where a flexible cooling strategy is required and to reduce the length of an air cooling system.