SMS group offers you complete tailor-made bar and wire rod mill solutions, including the latest and best technological solutions, comprehensive support, integration into existing mills, logistics, electrical, digital, and auxiliaries – and all with cutting-edge technology.

Single source, multiple solutions!

What is your product? Deformed TMbaR®?

Rebar mills are designed to produce ‘martensite-free’ products by drastically reducing microalloyed elements and transformation costs, thus improving weldability, ductility, and material homogeneity.

Wire rod? Which grade?

High-speed rolling mills are designed to obtain superb-quality wire rod – more precise than ever. They process any kind of steel grade at a low rolling temperature (750 °C) and product tolerances from ±0.05–±0.09 mm into wire rod 4.5–27 mm in diameter up to 50 % ovality (1/8 DIN 59110) at 130 m/s with MEERdrive®PLUS sizing technology.

-

High-speed delivery mill

Where limited investment meets higher productivity

High-Speed Delivery (HSD®) mills ideally combine limited investment with high productivity. A solution that guarantees a fast return on investment (ROI). Generally, these mills are sized for medium range production of up to 500,000 t/y. However, we can also reach big capacities of 1.6 million t/y (245 t/h endless with EBROS® welding technology) and 2.0 million t/y (330 t/h). HSD® mills are ready for the next challenge: to reach the speeds of 60 m/s and more on small products thanks to the next generation VHSD® (Very High-Speed Delivery System).

-

Multi-flexible rolling mill

The quick answer to economical solutions for high rolling production capabilities

Main dataMulti-flexible mills production can include flats, squares, hexagons, and light sections to complete the rounds and rebar production, produced at rates of over 200 t/h with over 250 products rolled into a single rolling mill. The rolling mills are characterized by lower overall investment costs compared to a solution with one (or two) high-speed finishing blocks and the associated additional electrics, piping, and civil works. This investment is partially offset by the need for two additional convertible stands without housings for multi-strand operations.

-

Light section mill

Great flexibility with a wide range of products

Main dataA modern merchant bar mill has the capacity to produce a variety of products, such as angles, squares, flats, and small channels. Round bars can naturally be produced, too. Such a mill is characterized by great flexibility and has an annual capacity of 500,000 to 600,000 t/y producing a broad product mix including plain rounds and rebars, flats, tees, angles and channels, and I-beams.

-

Special Bar Quality mill

Meeting market requirements with flexibility and precision

Main dataIn our Special Bar Quality (SBQ) mills we make use of the 3-roll PSM® (Precision Sizing Mill) technology – a high-precision and flexible solution for the finish-rolling of bars. With the PSM® one family, rolling in the roughing and intermediate mill as well as the infinitely variable production of all finishing sizes by using the free size range is possible.

The high roll force capacity allows thermomechanical rolling. The subsequent pieces of equipment, such as a cooling bed as well as a pouring reel line, are consequently designed for scratch prevention. The metallurgical aspects, like fast or retarded cooling, are considered in the equipment.

The right product at the right time: SBQ stands for stricter tolerances, repetitiveness, and defect-free products with fast deliveries.

-

Wire rod mill

Merging top quality, high productivity and low costs

Main dataThe wire rod mill is an all-rounder: creating high-quality components for the automotive and chemical industries through to the mechanical engineering and many other sectors. The solutions offered by SMS group for wire rod mills are correspondingly versatile. Dimensions from 4.5 to 27 mm diameter in all steel grades can be efficiently produced on such lines. Single- or double-strand high-speed wire rod mills from SMS group roll small dimensions with high production capacities of up to more than 1,000,000 t/y. Stable and constant speeds up to 120 m/s (130 m/s and more are the next challenge) are possible. Even at full speed, the rolling mills achieve a perfect laying pattern.

-

Combined rolling mill

Flexibility combined with higher productivity

Main dataA highly flexible and productive solution is the bar mill, which combines single-stand or two-stand rolling via high-speed finishing blocks and a two-strand HSD® High-Speed Delivery system. The presence of the finishing blocks easily facilitates a further extension for the production of wire rod or for the production of torsion-free coils with the VCC® Vertical Compact Coiler system. In combination with the EBROS® Endless Rod Rolling System, customized coils weighing up to 8 tons can be produced.

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

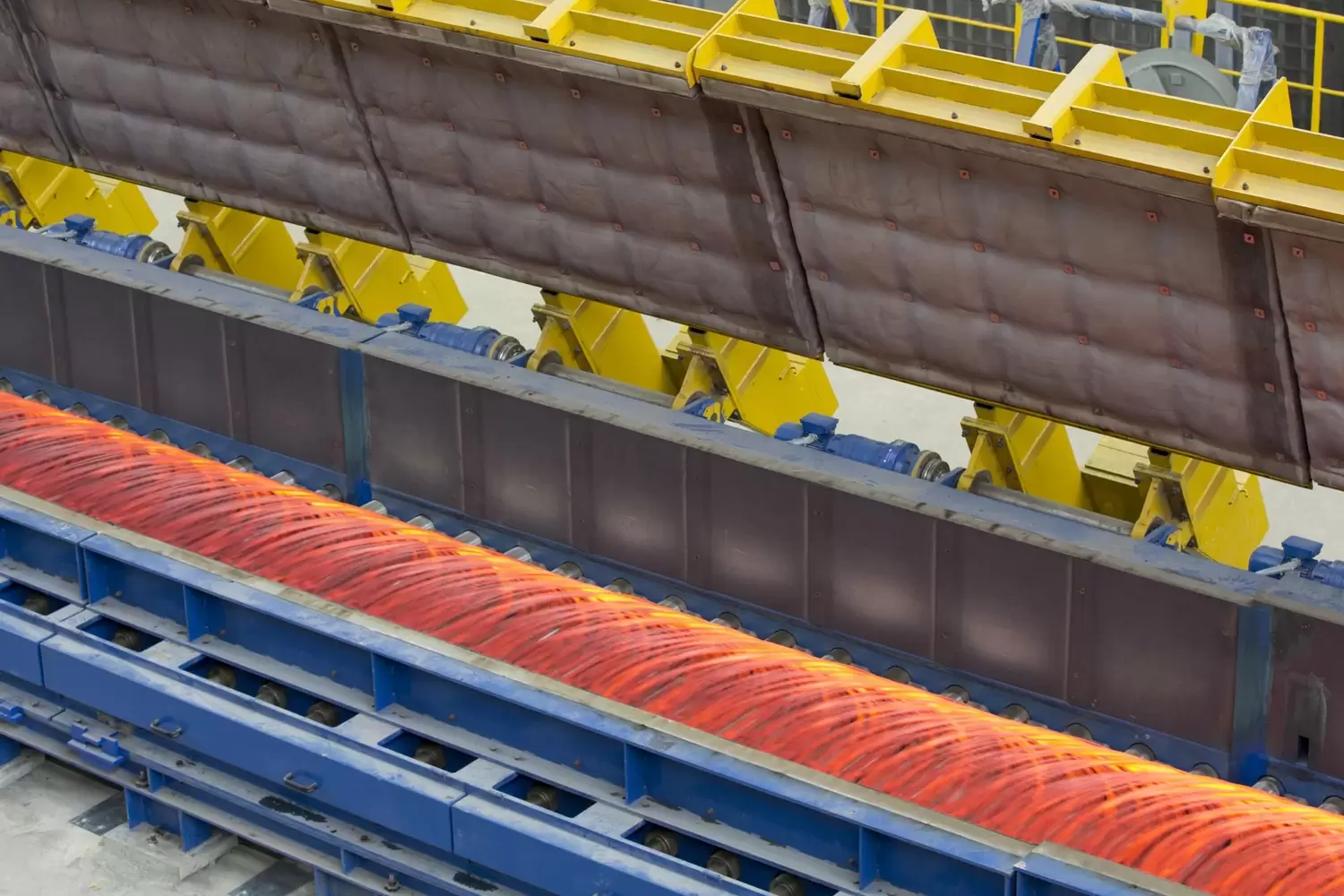

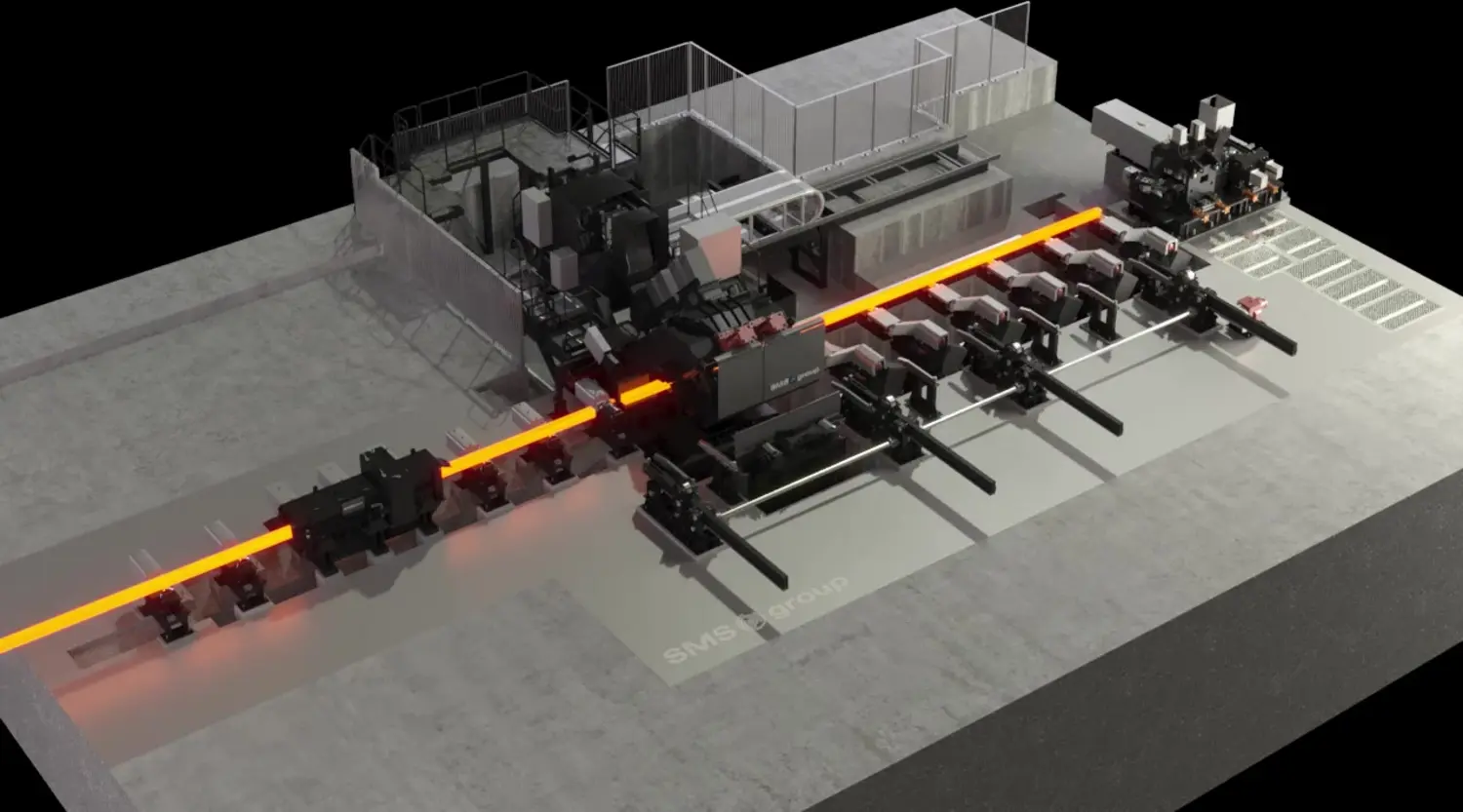

EBROS®

Endless Bar Rolling System

The Endless Bar Rolling System (EBROS®) is used to weld together successive billets while hot in a bar or wire rod mill line, to produce an endless rolling process. Welding is performed by the flash welding method, the properties of the welded joint after rolling are the same as those of the base material, and the joint is a saleable product. The endless rolled product is cut to the coil weights required by the customer after the cooling conveyor in the case of wire rod mills, and with the flying shear before the cooling bed in the case of bar mills. More than 10,000,000 billets have been welded together using this system.

Benefits

- Hourly production capacity increase up to 8 %

- Metallic yield improved up to 2 %

- No trimming operation required when producing wire rod (uncooled front-end and out-of-tolerances)

- Elimination of cobbles, head and tails cropping on the rolled stock

- Suitable for any layout application in case of new or existing plants