Precision-engineered bearings for backup rolls

Oil film bearings are essential for high-performance rolling mills, providing robust support for load-carrying backup rolls. Despite the harsh conditions in a rolling mill, our bearings deliver exceptional longevity with minimum maintenance, ensuring high dimensional accuracy and flatness of rolled products. Additionally, we offer extensive repair and modernization services, expert field support, and spare parts to keep your operations running smoothly.

SMS group has banked 70 years of experience supplying all generations of oil film bearings to rolling mills in the steel and non-ferrous industry worldwide. Today, you can identify our modern and cost-effective roll neck bearings by the SMS group trademark.

Customer challenges addressed

- Longevity of oil film bearings with minimal maintenance

- Minimization of downtime and avoidance of unplanned roll changes

- Reduction of lubrication system costs caused by increased oil consumption and leaks

- Safe handling of bearings, especially during roll grinding

- Older bearing designs often require special expertise

Key features

- Versatile compatibility with various rolling mills

- Reduced maintenance, minimized oil loss, higher plant availability

- Rapid delivery due to reserved manufacturing lots and warehousing of key components, minimizing downtime

- Comprehensive service: engineering, manufacturing, order handling, and after-sales support - all from a single source

- Optimized applications through know-how and experience over decades

- Efficient production in SMS workshops, benefiting from state-of-the-art facilities and expertise

-

Development and design

High precision and reliability

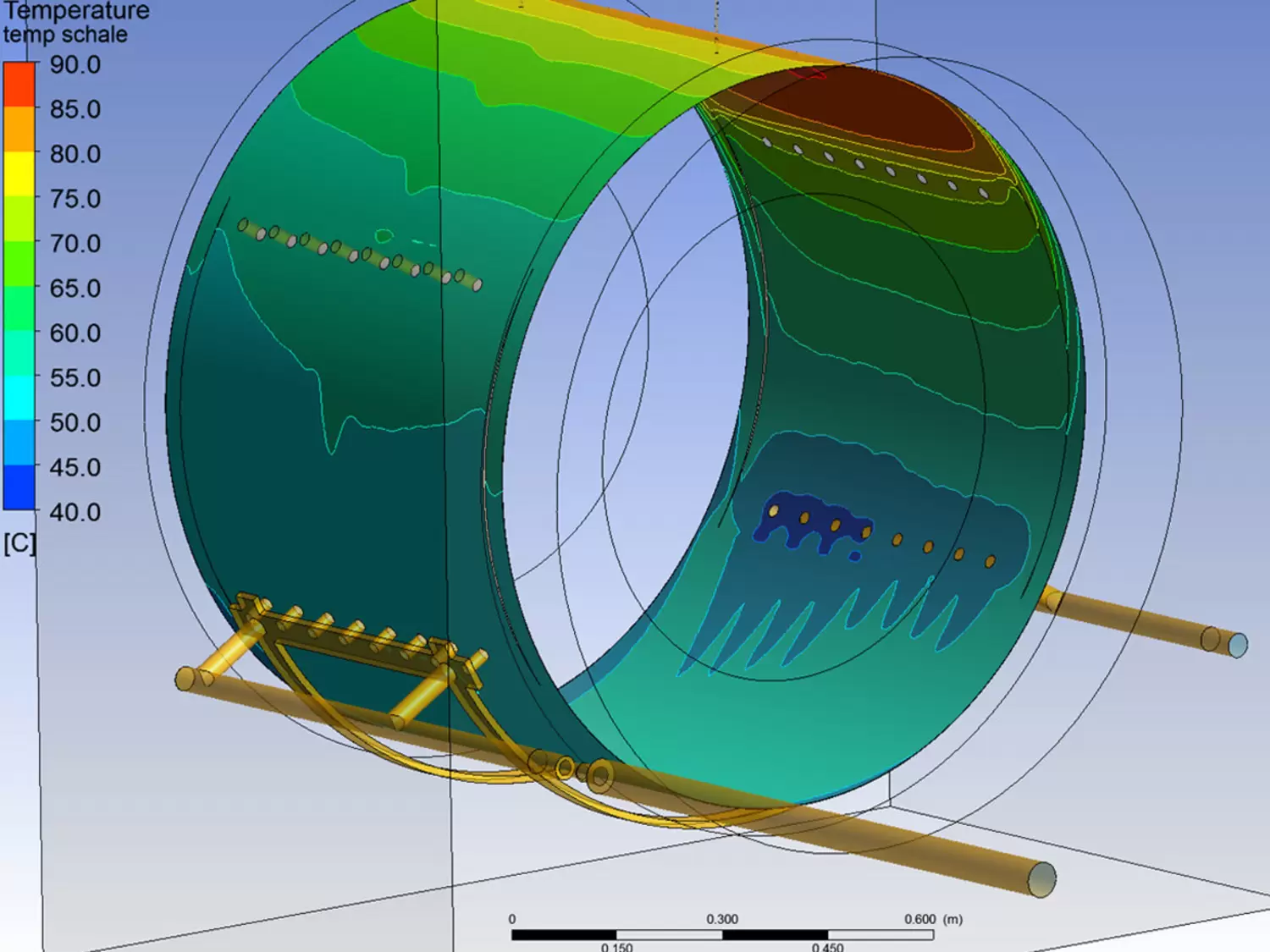

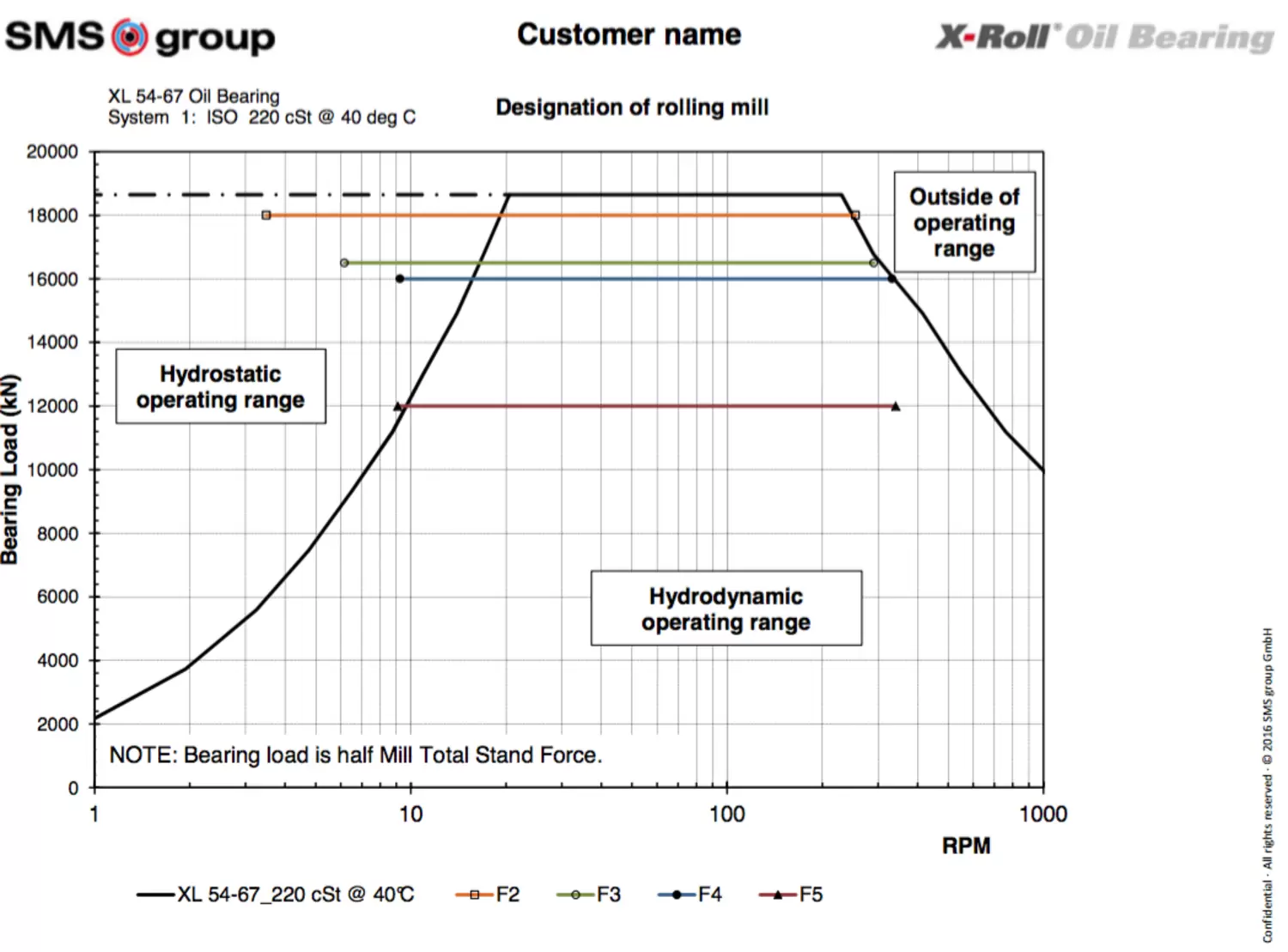

We continuously enhance our oil film bearing technology, offering expert advice on new solutions, upgrades, and repairs. Our design team uses CAD software for 3D modeling and FEM analysis to optimize components. To validate and update our bearing dimensioning software, we regularly record bearing data under true load conditions in mill stands. Using model techniques, we simulate the fluid flow and physical properties and analyse the elasto-hydrodynamic behavior of the bearing.

![]()

![]()

![]()

-

Manufacturing

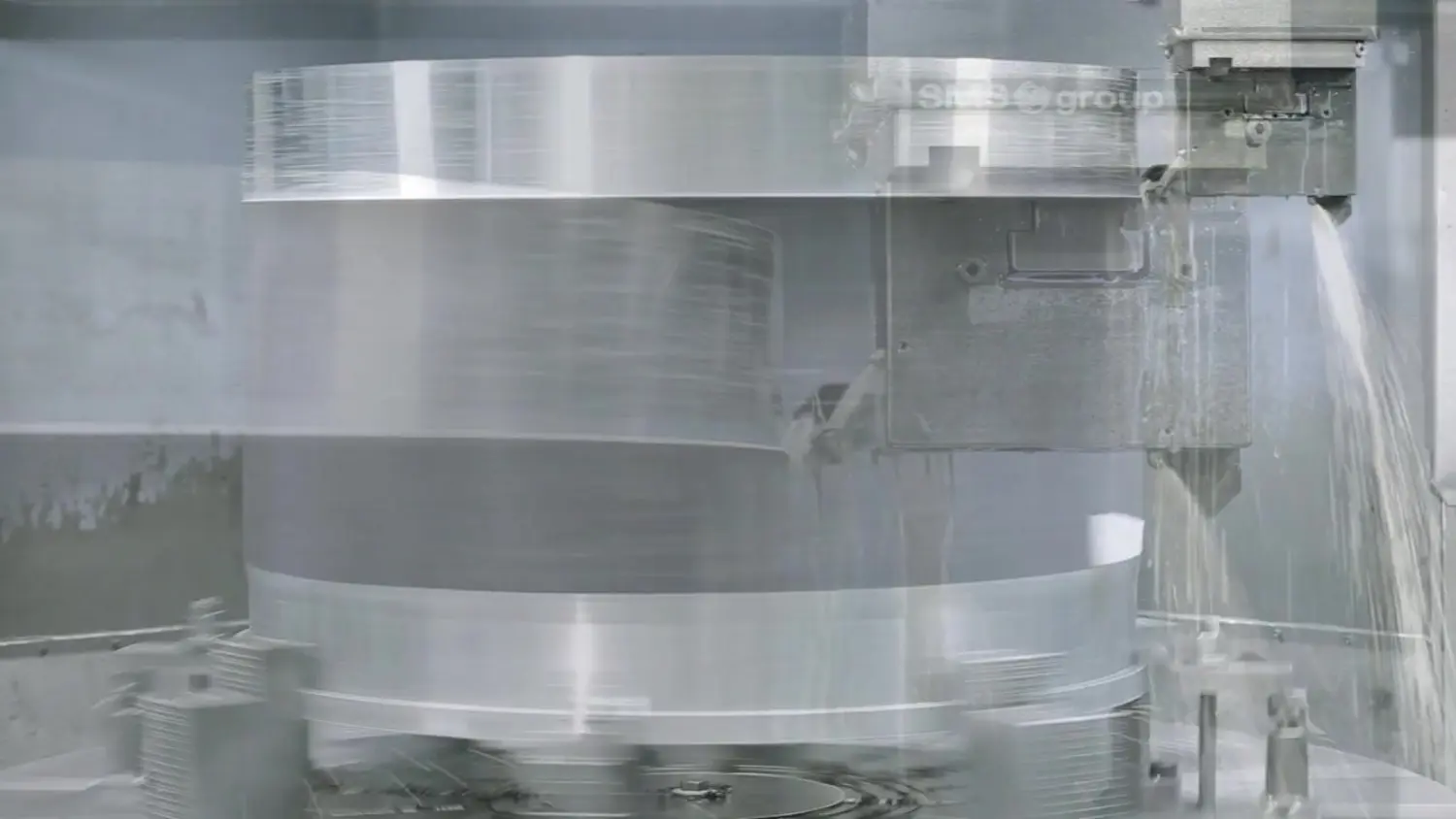

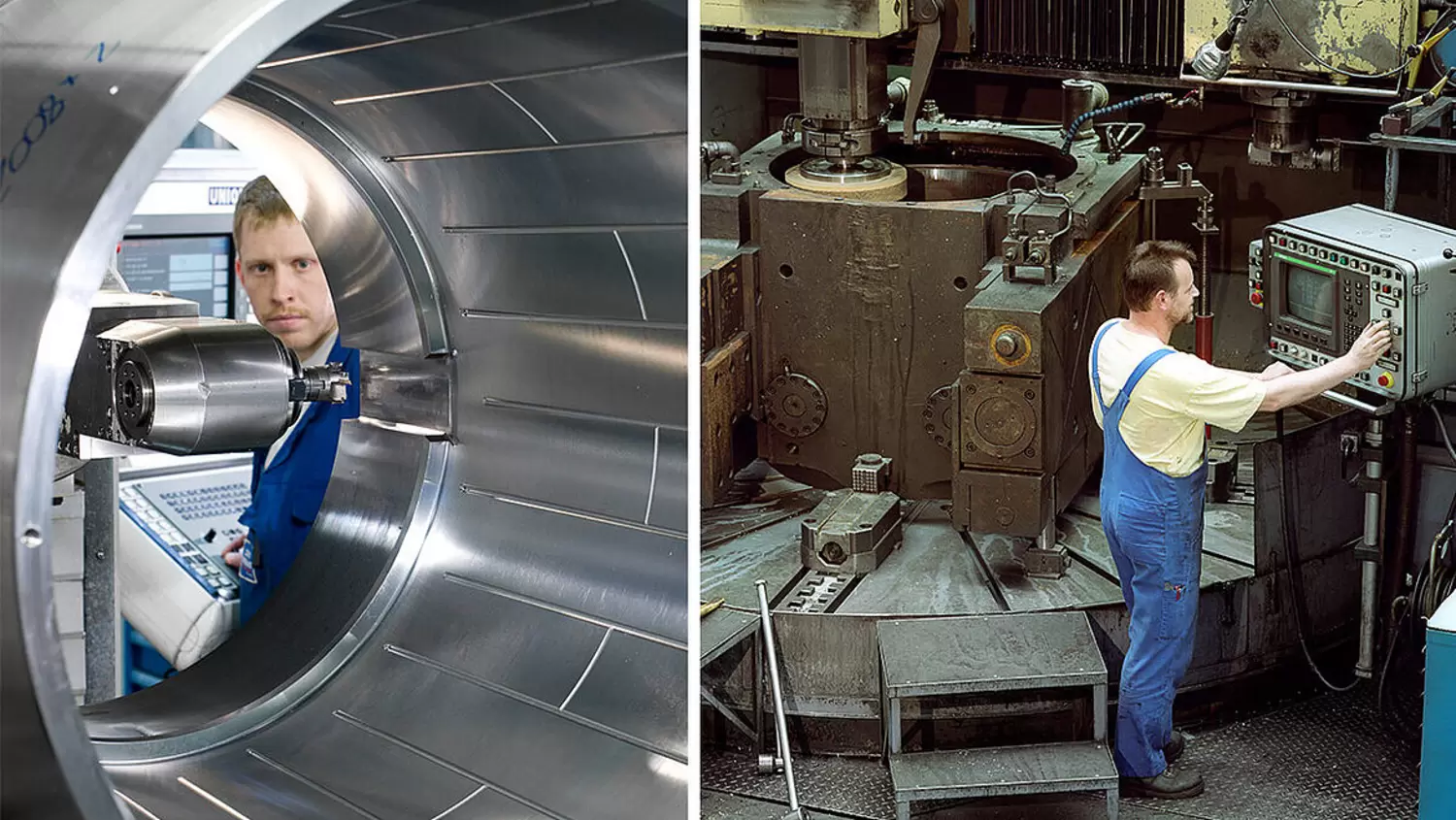

Competence in manufacturing for high precision and reliability

Included among the rolling mill components essential for strip quality are the bearing housing for work and backup rolls, and the bearings themselves. Our focus on the technical demands of these complex components forms the basis for regular investment in our workshop. This is where our special machines give each component the right finish.

Efficient processes and modern technologies in manufacturing, such as plasma soldering of bushings, ensure consistent high quality.

-

Spare parts and repairs

Original-equipment-manufacturer (OEM) quality

No matter the brand of oil film bearings you use, including X-Roll® Oil Bearings, SMS group provides top-quality spare parts to ensure efficient plant operation. Our expert repairs cover main bearing components such as regrinding sleeves, repairing bushings with babbitt replacement, and reconditioning and retrofitting roll chocks, all maintaining OEM quality and reliability.

![]()

-

Value-added customer training and service

Technical support in your roll and bearing shop

While rolling mill operation is going on, the operational change rolls and bearings are machined and prepared in the roll and bearing shop. That boosts your productivity because high-quality and high-performance mill components such as oil film bearings are crucial to meeting ever-higher quality requirements.

Wherever in the world you are, an SMS group service team is only a phone call or a click away. So you can count on rapid, uncomplicated, and flexible support every time.

Our X-Roll® Oil Bearing specialists work with your roll and bearing shop as well as maintenance teams to analyze weak points. Then they initiate the necessary steps so your system works perfectly.

![]()

Preventive maintenance support -

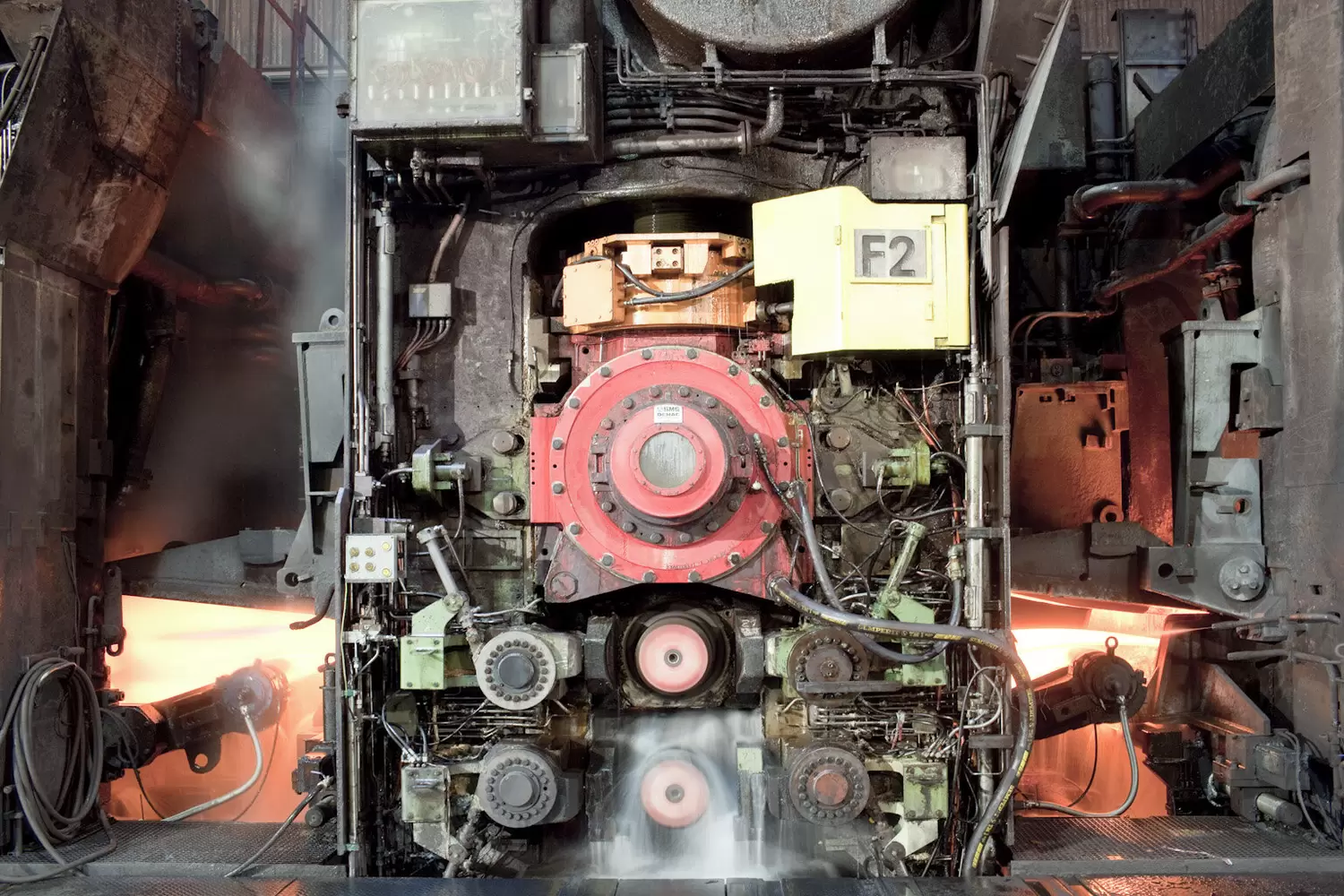

Modernizations

State of the art backup rolls and oil film bearings

It makes sense to revamp and extend older mills so they can handle today’s challenging products. That ensures your long-term competitiveness.

Included in the critical components are the backup roll and bearing unit. To start with, we team up with you to determine the current status of your bearing system. Then we perform a thorough analysis. This is how we identify what optimizations will get the best out of your system. There is plenty of scope for practical improvements in areas such as safe handling of the bearings or better sealing systems. These can make all the difference.

That’s where our design ideas and systematic improvements come in. They cover all components – from the bearings and their chocks to the roll necks and oil lubrication systems. Our modernizations ensure your bearings achieve the high standards of occupational safety, reliability, and cost-effectiveness to guarantee your success.

![]()

Use our contact form for questions, inquiries or personal contact.