Available to you from SMS group are all plants and know-how you need for the industrial production of high-quality copper semi-finished goods. Our portfolio covers almost the entire production chain of metallurgical plants. Stretching right up to transfer to the cold mill, our supply range covers smelting furnaces, strip casters and hot mills.

-

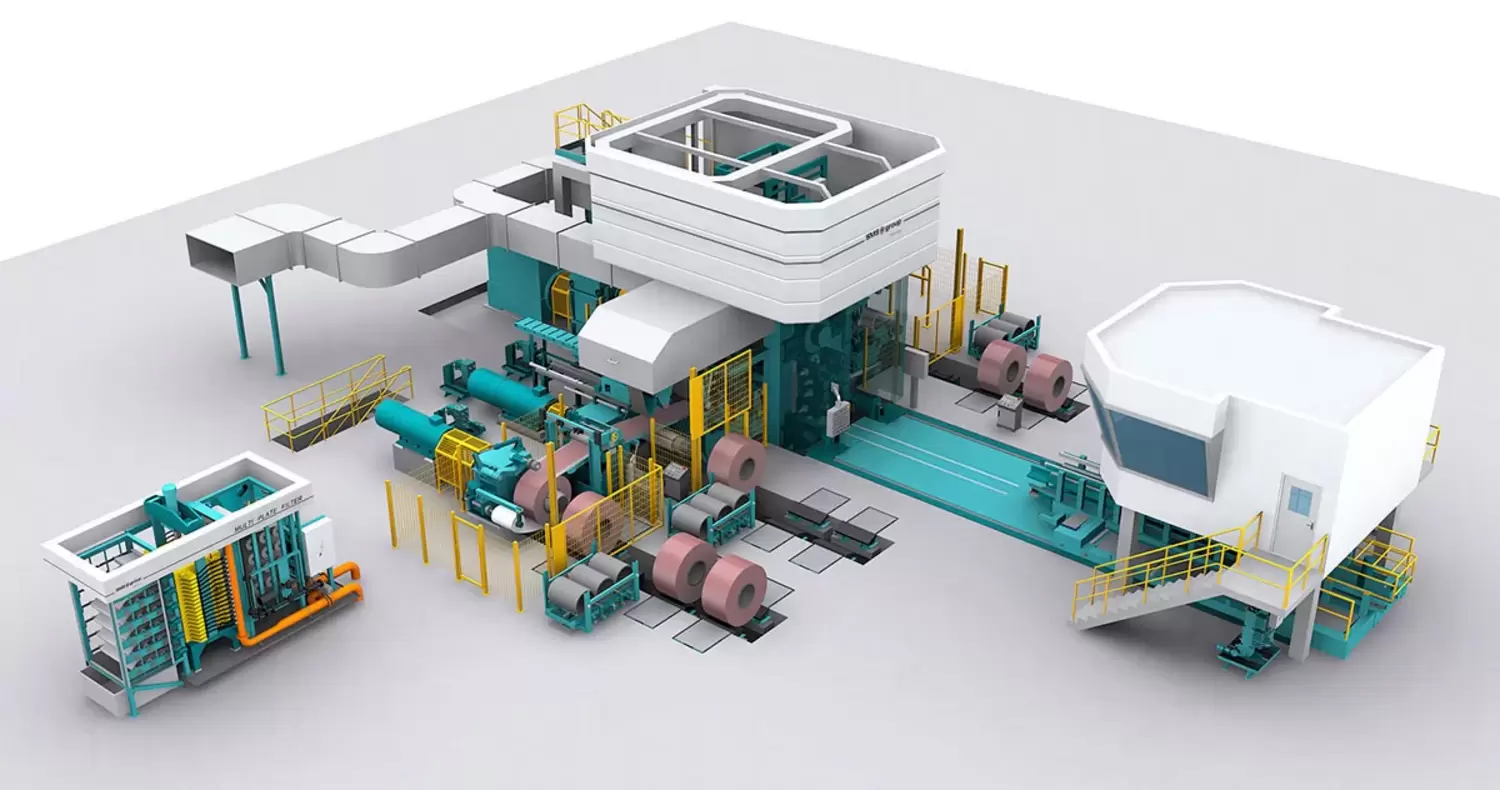

Hot rolling mills for copper and copper alloys

Variety and performance

SMS group supplied a two-high hot rolling stand with a fully hydraulic edging stand at the entry side to Wieland-Werke, Germany, a leading producer of copper and copper alloy semi-finished products. The mill is capable of reverse-rolling blooms weighing up to 16 t to widths of between 580 and 840 mm and thicknesses of 8.5 to 25 mm. Also included in our supply package were a coilbox with additional heat hood for temperature balancing before the final pass, strip cooling equipment, and a cooling bed just 700 mm high.

Our portfolio of the specific hot rolling equipment comprises:

- Reversing mills

- Tandem mills

- Coil boxes with heat insulation hoods

- Edging stands

- Cooling beds

![]()

Hot rolling mill for copper -

Copper cold rolling mills

Maximum utilization of valuable material in every process step

The material requirements of copper and copper alloys, including brass, bronze, and ever more new materials, are what determines the design of a cold rolling mill. It depends on your product mix and its required capacity whether the best solution is a tandem non-reversing or a reversing cold mill. SMS group offers you CVC ®plus 4-high, CVC ®plus 6-high, and 20-high stand designs. Furthermore, we provide optimal mill solutions for all your rolling tasks. Typical processes are roughing, roughing and intermediate rolling in one mill, intermediate and finish rolling in one mill, and finish rolling.

![]()

-

Roughing cold mill

Target gauge across the entire strip length

Main dataThe input stock from the casting plant or hot rolling mill is up to 16.0 mm thick and wound into loose coils with variable inner diameters. To handle the large strip gauge variations, the entry and exit stations consist of a combined payoff gear and payoff drum with various reel diameters. The reversing cold mill is a 4-high type. Crucial here is that the thick, relatively short strip goes into the closed roll gap so it is completely rolled from end to end before emerging. Then it is re-threaded for the reverse pass.

![]()

-

Roughing and intermediate cold rolling

One mill for two process steps

Main dataTandem cold mills for roughing and intermediate rolling are all-rounders. That’s because they roll a wide range of copper and copper alloys to many different dimensions and gauges. Among SMS group’s references is a powerful TCM able to process entry gauges of up to 20.0 millimeters. The minimum final gauge from this type of mill is 0.5 millimeters. You can choose between CVC® plus 4-high and CVC® plus 6-high design.

![]()

-

One mill for intermediate and finish cold rolling

RCM qualified for final gauge

Main dataSingle-stand reversing cold mills in CVC® plus 6-high design featuring small work rolls effectively roll the ingoing material to your required final thickness and surface quality. Impressive are the available capacities from 100,000 to 150,000 tons per year.

![]()

-

Finish rolling of copper strips

20-high mill for ultra-thin strips

Main dataIdeal for ultra-thin rolling of copper strips, 20-high mills from SMS group come in either Monoblock or Splitblock design. They process a wide range of materials and guarantee flawless surfaces of even thin strip – with a minimum final gauge of 0.05 millimeters. Typically, these top-quality strips are used in the electronics industry. Important applications are lead frames and semi-finished products for further processing in LED technology. The material is also essential in semiconductor technology.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Superior design and actuators for roll gap setting

Better yield and quality

Outstanding CVC® plus 4-high and CVC® plus 6-high designs for better yield and quality, proven by more than 800 installed systems.

![]()

Benefits

- Shifting under all load conditions

- A very large roll gap adjusting range for flexible handling of a wide variety of incoming hot strip profiles

- Top flatness results

- Excellent strip quality due to uniform load and roughness transfer

- Low operational costs with less roll wear and less maintenance