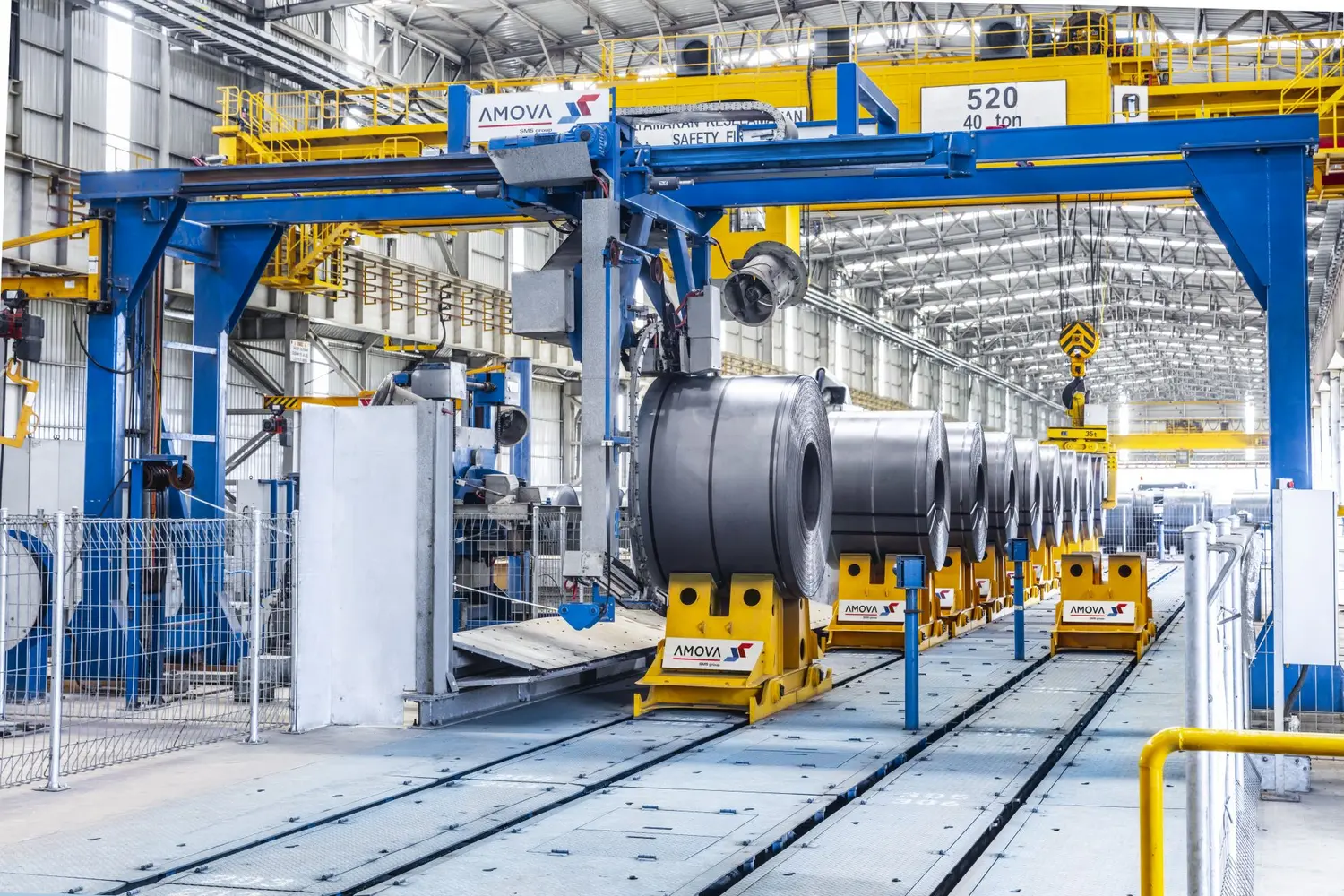

Pallet conveying systems

Perfect transport solution for hot-strip coils

AMOVA pallet conveying systems can be used to transport hot-strip coils reaching temperatures of up to 850 °C at a travel speed of 0.5 m/s.

AMOVA further-developed the usual method of pallet transport for cold-strip lines some years back and adapted it for operation in hot-strip rolling mills. All components were tested and technically optimized. Specially designed roller table segments in modular design are now supplemented by a pallet concept that excludes thermal deformation of the runners.

The system guarantees extremely careful material transport, since after being placed on the pallet the coils are not moved again. It offers great flexibility in routing combined with minimum spare parts stockage; empty pallets are optionally transported away under or parallel to the load conveyor. The pallet transport system is not bound to a fixed cycle. Which means it can also be decoupled from other systems or processes and used as a material buffer. All transport movements are powered by electric motors, so reducing the scope of hydraulic equipment to a minimum. Likewise the outlay for foundation work.

Thanks to standardized component parts and small, lightweight assembly units the systems are easy to assemble, install and maintain. By comparison with other systems an extremely cost-effective solution providing maximum throughput.