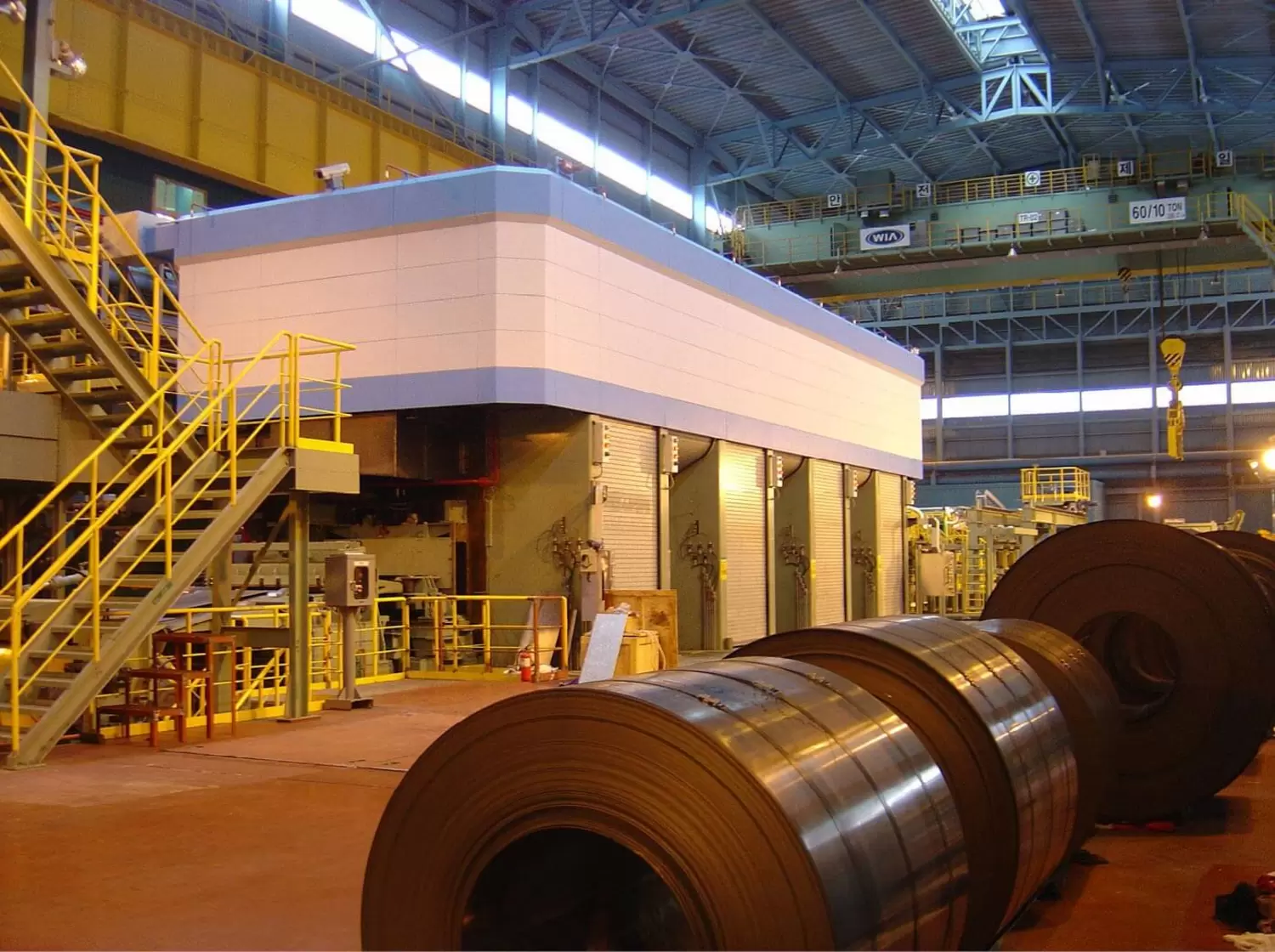

18-HS design: Continuous tandem cold mill (CTCM)

For production capacities of up to 1 million tons

Main dataA tailor-made plant concept that is second to none... economical production of high-quality cold-rolled strip on a continuous 18-HS tandem rolling mill. It is the most cost-effective option, if you aim for an annual capacity of more than 400,000 tons. Compared with using individual reversing mills for large production volumes, a tandem mill means lower investment and operating costs.

First in line here is the continuous entry section. It includes these machines: double pay-off reel, crop shear for the strip head end, welder, strip accumulator, and strip cleaning section. Downstream of that, the tandem mill consists of up to five stands in 18-HS design plus a powerful pinch roll unit on the exit side. Also designed for continuous operation, the runout section features a double tension reel.

All 18-HS mills can come with our CVC® plus technology. Using the special CVC® plus roll contour means you can correct more severe flatness defects over a wider range than with other approaches. You also benefit from easy, fast work-roll and intermediate-roll changing.