Based on positive experiences acquired in the introduction of the IMMS® (Integrated Maintenance Management System) data package into the existing SAP-PM module for the main facility in 2017, NLMK DanSteel A/S (Denmark) has placed an order with SMS group to implement another IMMS® data package. This provides NLMK DanSteel with an efficient tool that enables plant servicing and maintenance to be completely planned and organized.

Through this data package, the planning department is able to generate maintenance schedules automatically including the required documentation, and receives information on the duration of individual measures and necessary resources such as manpower and spare parts. The local maintenance crews execute these plans giving feedback to the system. This ensures a comprehensive history of the entire servicing process including historical outages and relevant costs.

Effective KPI controlling system

Based on these data, an effective KPI controlling system can be established with the IMMS® data package. There is the possibility that purely technical KPIs such as Overall Equipment Effectiveness (OEE), MTTR (Mean time to repair), MTTF (mean time to failure) etc., as well as cost-related evaluations are implemented. This makes sure that the plant management from DanSteel A/S is in the position to start a CIP (Continuous Improvement Process) and to improve the efficiency from a technical and commercial point of view from one planning period to another.

Preventive maintenance

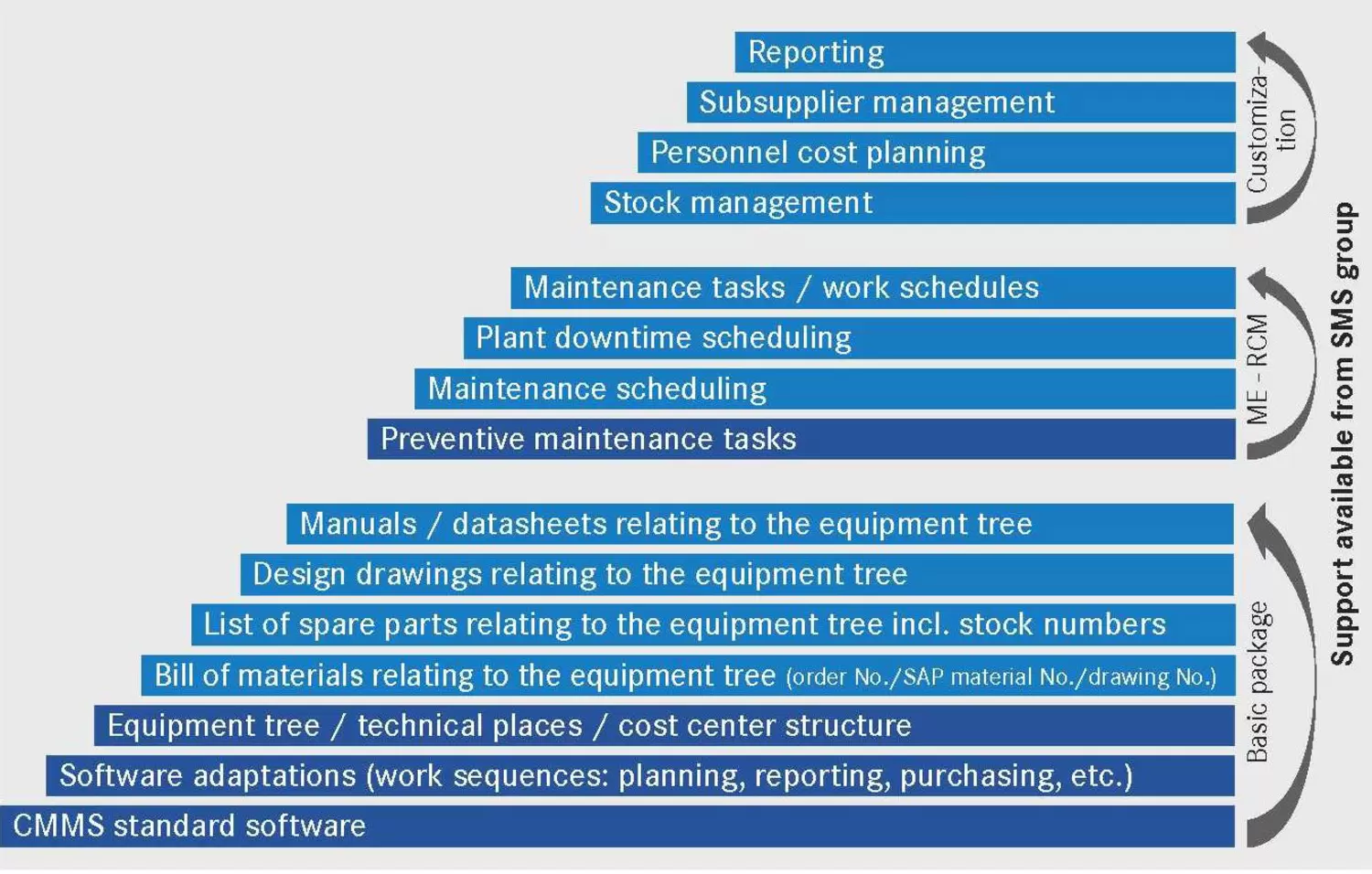

IMMS® supports the expansion of an effective servicing planning with the aim to optimize preventive maintenance ensuring plant availability and the quality of the end product in the long term. For that reason, a maintenance data package is supplied by SMS group. IMMS® is a combination of maintenance software (Computerized Maintenance Management System, CMMS) und valuable information based on experience in servicing for many decades. Here, the material flow of the complete plant is displayed except the functional locations and all technical parameters are incorporated to establish a reliable basis for effective servicing planning and organization. Each component to be maintained is clearly identified and coded in the plant tree and thus assures target- and purpose-oriented servicing ensuring an economical management of the complete plant.

Modernization of heavy-plate mill

The installation of the new IMMS® package comes along with the comprehensive extension and modernization of the heavy plate mill of NLMK DanSteel in Frederiksvaerk. It includes the integration of a laminar cooling system with water management, the assembly of a new heavy plate cooling bed and the modernization of the cold-plate straightener. With these measures, NLMK DanSteel A/S intends to further extend its product range regarding grades and dimensions.