SMS group delivers pickling lines from a single source as a system supplier. The lines are outstanding for their high pickling performance as well as low maintenance and operating costs over a long service life. With the ECO production and pickling model and various other innovations, it has become possible to increase the performance still further.

-

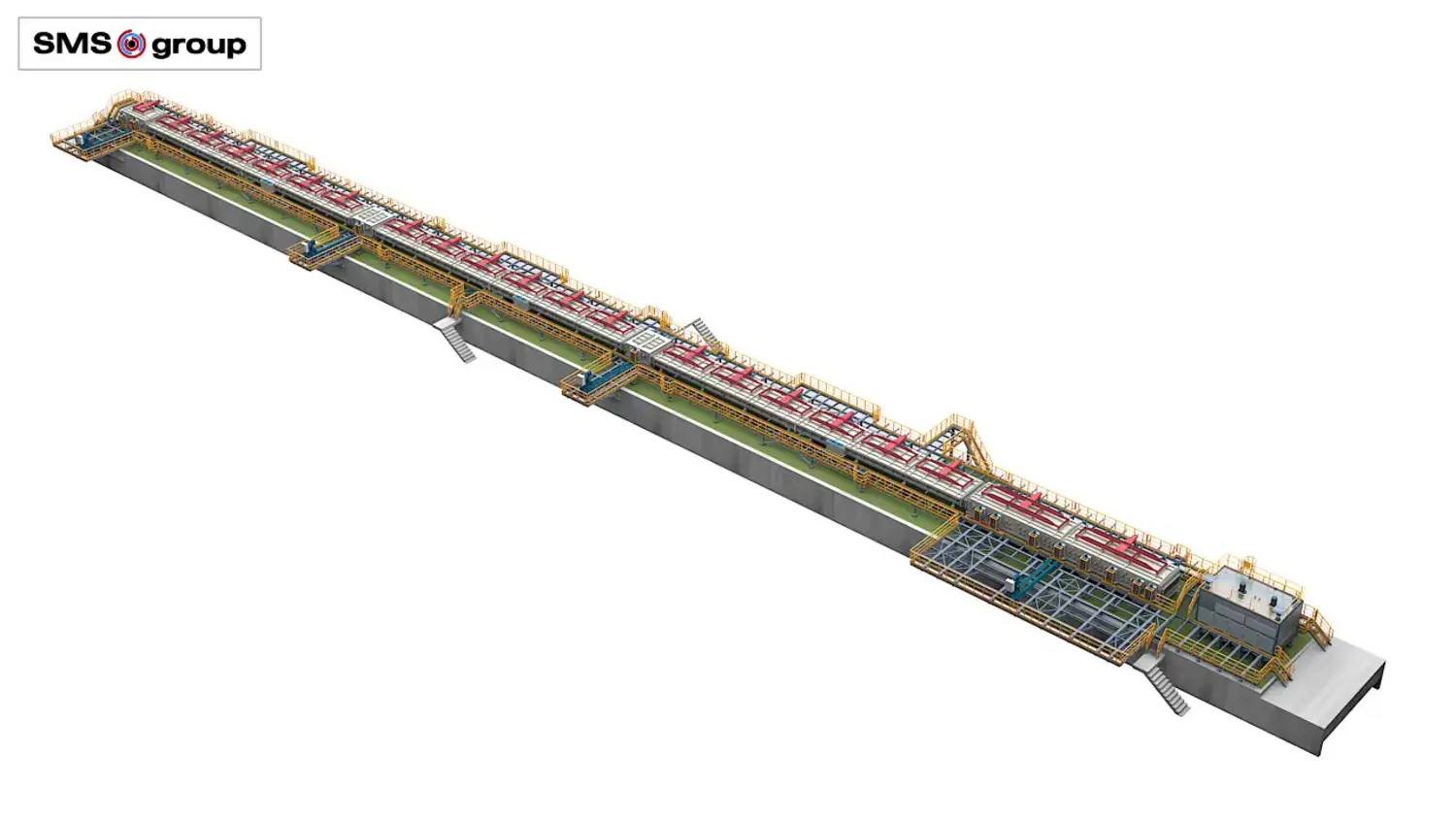

Continuous pickling line (CPL)

Stand-alone pickling line

Main dataA welding machine at the entry of the continuous pickling line joins individual strips into endless strip, then horizontal loopers ensure continuously high speed in the processing section. That means you achieve top quality standards at very high capacities. Continuous pickling lines can also be coupled to cold rolling mills.

![]()

Continuous pickling line Gazi metal -

Pickling line / Tandem cold mill (PLTCM)

Pickling and cold rolling in a single line

Main dataThese mills continuously pickle and cold-roll hot strip in one go. They come with three loopers to ensure a continuous process. Both the entry and exit areas are designed for continuous operation at high speed.

![]()

Pickling line / Tandem cold mill

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Turbulence pickling technology

Most efficient descaling without overpickling

Outstanding features of the turbulence pickling system are a high kinetic energy, the flat pickling channel, immersion cover and hydrodynamic seals to separate the cascades.

Racks of nozzles are constantly spraying heated hydrochloric acid into the shallow pickling channel and generate an extremely high turbulence. This ensures maximum contact between the acid and the strip surface by continually forcing fresh acid into the cracks in the scale layer. It only takes a short time to create the required electrochemical potential which results in fast and efficient pickling. The patented immersion cover above the pickling channel closes off the acid bath surface, minimizing evaporation losses by 30 % and the heat losses by 70 %. Furthermore, the exhaust system requires a smaller volume, which again reduces losses.

-

Sludge removal

Proven two-tank system

Our two tank system is most efficient when it comes to sludge removal in carbon steel pickling lines especially for AHSS-grades with high silicon contents.

SMS group has huge experience with electrical silicon steel grades with high silicon contents. The proven two tank system can be used for sludge removal in carbon steel pickling lines when it comes to AHSS-grades with high silicon contents. Here, two tanks are integrated and are used alternating as circulation and sedimentation tank.

Furthermore, a settling tank should be included before the waste acid flows into the regeneration system. This increases the efficiency of the acid regeneration and helps to remove the silica content out of the process.![]()

Tanks for sludge removal -

Acid regeneration plant

Compliance with all environmental standards

Acid regeneration plants for hydrochloric acid are an outstanding example of green and efficient technology. Depending on the individual customer requirements, spray roaster or fluidized bed technology is used. These systems put the regenerated acid back into the process and produce a valuable by-product.

All resources are circulating in a closed-cycle inside the plant. Even considering only the saved transportation costs for waste acid and rinse water, which do not have to be neutralized, savings of more than EUR 250,000 per year are possible for a conventional pickling line.

![]()

Acid regeneration plant -

X-Roll® laser welder

Fast, safe, and successful welding of challenging steel grades

The X-Roll® laser welder is designed to join hard-to-weld strip material. The laser welder comes with a patented, inductive heat treatment system including automatic welding parameter calculation system, a quality assurance system, and an exchangeable laser source. The laser welder has been installed in new plants as well as in modernization projects.

The X-Roll® laser welder is controlled by X-Pact® automation. The control system is designed as a package unit with its own basic automation and X-Pact® Vision HMI system.

![]()

Laser welder -

X-Pact® Strip Process Optimizer

A key to increasing the efficiency of modern processing lines

X-Pact® Strip Process Optimizer is a key to increase the efficiency of modern processing lines. It is integrated into all activities regarding engineering, commissioning or research and development of strip processing lines. In addition to its role as a data hub, improving product quality and increasing production volume and flexibility are the main tasks of our Level 2 solution, which is partly based on mathematical and physical process models. X-Pact® Strip Process Optimizer guarantees maximum reliability, increases process stability, reduces downtimes and enables a high degree of independence in production.

![]()

-

Scale breaker

For high-strength materials

Scale breakers minimize irregularities such as waviness, cambers or length- and crossbows by a combined tensioning and leveling action to create a flat final product. An additional task is to break the scale layers by alternate bending and stretching to ensure better pickling medium efficiency and hence a faster pickling process.

Bridles ahead and behind the bending roll stand build up the required strip tension and are mechanical with individual drive for each bridle roll. The scale breaker will be controlled to improves the flatness of the strip and additionally to break the scale layers by alternate bending and stretching.

The scale breaker automation control performs the following functions:

- Interlock logic and switching functions for the scale breaker main, compensation and/or superposed drives

- Load compensation control that ensures a defined torque distribution between the individual level rolls

- Speed control of entry and exit bridle roll set

- Automatic control functions for cartridge replacement

- Control of the magnet valves for movements

- Elongation measurement and control

![]()

Scale breaker -

Process control

X-Pact® Basic Automation

Stability, simple maintenance, uncomplicated adaptation to new conditions, and high-tech solutions – these are the demands modern automation systems must meet. Our X-Pact® systems are completely modular in structure. As a result, we can easily adapt them to the different requirements of individual strip processing lines.

![]()

Control station of a new line for pickling and galvanizing of strip at Nucor Steel Gallatin, USA -

X-Pact® Line Drive Control

Well coordinated, service-friendly, and proven

Essential for reliable, low-wear operation of processing lines is a well coordinated, service-friendly, and proven drive control system. Our innovative line drive control is an Integral part of X-Pact® electrical and automation systems and is combined with optimal drive hardware. Our low voltage frequency converter X-Pact® Drive is extremely energy efficient ans ensures a high line availability.

![]()

Low voltage frequency converter X-Pact® Drive

Services for this plant

Sorry, there are no results for the search term.