Enhancing efficiency and reliability through advanced leak and anomaly detection

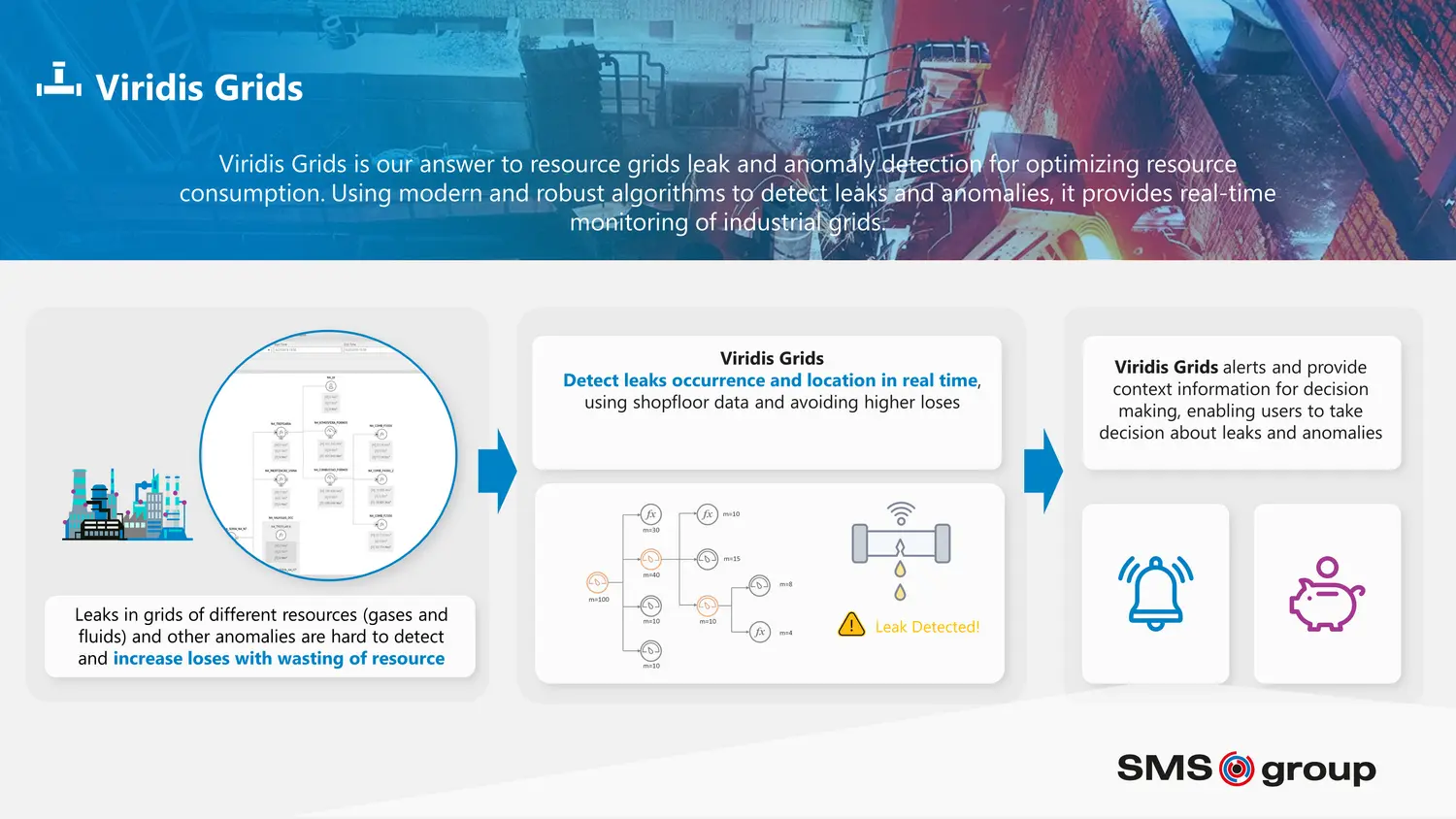

In the complex and demanding environment of manufacturing, efficient management of resource grids is paramount. Factories often face significant challenges such as undetected leaks, blocked points in the grid, and other anomalies that can lead to inefficiencies, increased operational costs, and unplanned downtime. These issues disrupt production and have a detrimental impact on sustainability efforts. Addressing these challenges requires a robust and intelligent solution capable of providing real-time monitoring and precise anomaly detection like Viridis Grids.

Our sophisticated software solution is designed to monitor resource grids in industry, covering different resources such as electricity, gases and fluids. Viridis Grids leverages advanced data collection and analytics technologies to provide real-time insights into the status of resource grids. Viridis Grids collects data from various points within the factory, which is then processed and analyzed using machine learning algorithms and leaks detection algorithms. This allows Viridis Grids to detect the occurrence and location of leaks and other anomalies and malfunctions, enabling maintenance teams to address problems before they escalate into major disruptions. The system's ability to provide early warnings and detailed diagnostic information is crucial for maintaining continuous production flow and avoiding costly downtime.

Moreover, Viridis Grids integrates seamlessly with other applications on the Viridis platform, offering a unified approach to energy and resource management. By harmonizing data from multiple sources, it creates a holistic view of the factory's resource usage, allowing for more informed decision-making. This integration also facilitates the implementation of coordinated strategies to enhance energy efficiency and sustainability across the entire production process. Overall, Viridis Grids stands out as a critical tool for modern factories aiming to improve their resource management, reduce environmental impact, and achieve long-term operational excellence.

Customer challenges addressed

- Difficulty to early detect leaks in resource grids within the factory

- Resource wastage and increased costs due to leaks and other anomalies in the grids

- Obstructions disrupt the flow and distribution of essential utilities, affecting efficiency

- Inefficiencies in resource management lead to higher operational expenses

- Absence of real-time data makes timely issue identification and resolution challenging

- Difficulty in achieving sustainability targets without precise resource monitoring and management

Key features

- Continuously track your grids’ resource across the factory

- Detect leakages, blockages, and other irregularities in resource grids by using advanced algorithms

- Benefit from early warnings and detailed diagnostics to prevent major disruptions and unplanned downtime

- Detect instrumentation failures faster

- Discover leaks in their earliest stage to reduce financial losses with resource leakage

-

Viridis Grids addresses industry challenges in data collection

Viridis Grids maximizes efficiency by leveraging the Viridis Suite and industrial ready-to-use connectors, enabling seamless data collection from various sources within industrial complexes. It also offers an Software Development Kit for expanding connector options and includes built-in data cleansing functionality.

![]()

-

Integration with other Viridis products enhancing resource management

With seamless integration with other applications on the Viridis Energy & Sustainability Suite, Viridis Grids offers a unified approach to resource management, harmonizing data from multiple sources for informed decision-making.

-

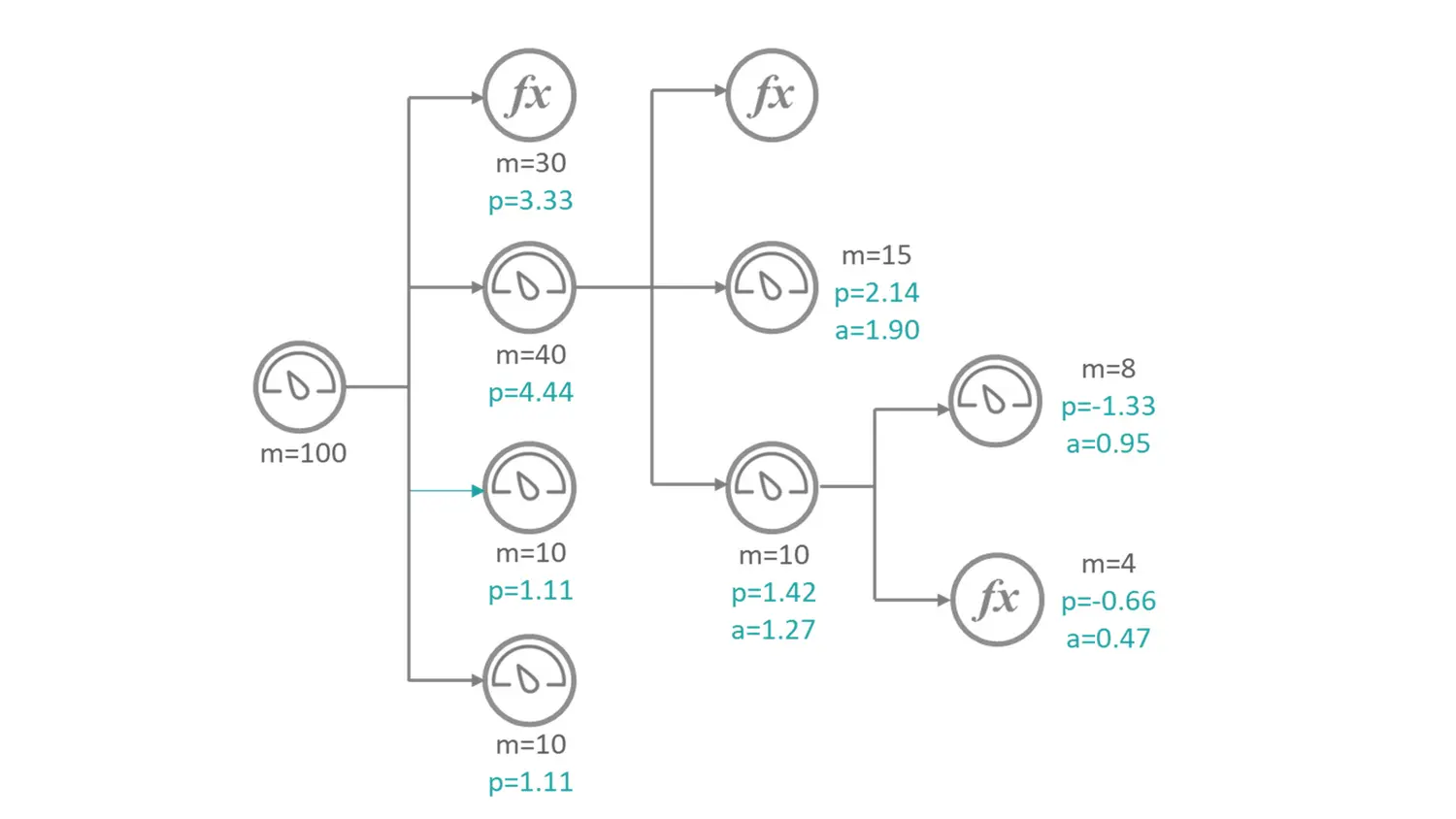

Improve resource accuracy and efficiency with hierarchical meter balancing in Viridis Grids

Viridis Grids allows meters to be organized hierarchically, enabling explicit balancing relations between parent meters and their children. This feature not only ensures accurate measurement but also facilitates the detection and correction of unbalanced relations, which can prompt alarms indicating leaks or measurement errors. The platform provides tools to re-balance meter grids by allocating differences between parent meters and their children, enhancing accuracy and optimizing resource management.

![]()

-

Empower operators with rule-based smart event detection for leaks and anomalies in Viridis Grids

Viridis takes proactive monitoring to the next level with rule-based smart event detection. Viridis Grids not only identifies leaks and anomalies in real time but also triggers targeted actions for operators. By leveraging intelligent algorithms, Viridis ensures swift response to critical events, enhancing operational efficiency and minimizing disruptions. With customizable rules and automated alerts, operators can stay informed and take proactive measures to maintain smooth operations.

![]()

Use our contact form for questions, inquiries or personal contact.