X-Roll® MultiFlex treatment technology – Customized properties for high-grade plates

Our heat treatment lines (HTL) enable the economical and energy efficient production of a wide range of special steel grades with extremely demanding qualities. These plates are employed in growth sectors such as wind energy, power engineering, tubes and pipelines, mechanical engineering, heavy vehicle engineering and more.

Our flexible, future-oriented overall concept is based on proven and innovative system components. Especially our X-Roll® MultiFlex-Quench is setting standards for plate production. By predicting the mechanical properties with the material property model for the entire heat treatment process, operators can optimize the whole process and develop new products in a cost-effective way. We supply the entire process chain from a single source and thus the highest quality.

When investing in a heat treatment line, you will earn access to the new growth markets

- Because you will be able to offer even niche products profitably

- By efficiently developing new products, supported by our material property model

- By utilizing our broad portfolio of services, covering the entire life cycle of the equipment and digitally managed maintenance services

- By saving valuable resources through our digital plant solutions

-

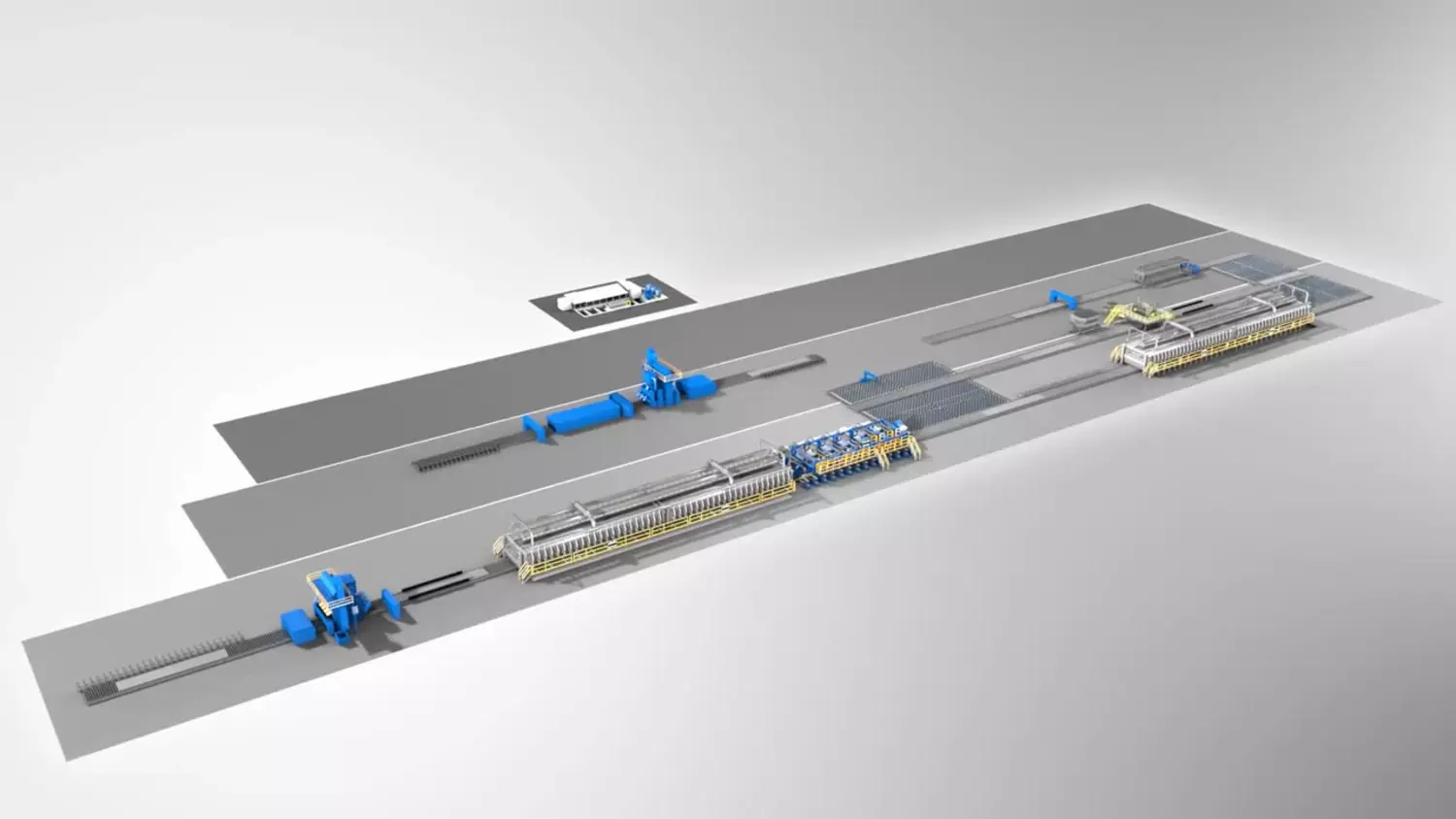

Complete heat treatment line

Top quality plates

The key process for setting the material properties comprises mainly water cooling. SMS group has accumulated extensive experience in the development of plate cooling and quenching systems.

SMS group has further developed the spray-cooling system concept and the conventional roller-type quench and adapted it to the heat treatment process. The progressive development of the mill’s proven, rigid design resulted in the X-Roll® MultiFlex-Quench. All the features of established plate cooling systems and quenching systems were combined and innovatively planned in advance.

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Roller-type shot blasting machine and primer line

Perfect surface cleaning

In the roller-type shot blasting machine the plate is prepared for further treatment in the downstream processes. It cleans the plate surface of scale and impurities, so that an even heat transfer is guaranteed, when the plate is heated in the furnace and cooled in the X-Roll® MultiFlex-Quench.

The shot blasting machine can also be part of a primer line. Complete primer lines consists of individually adaptable conveyor systems, a preheater, a shot blaster, the color coating system and a downstream dryer. The preheater unit also allows the processing of materials that is stored outdoors. The dryer dries the protective layer, which is applied by the automatic painting machine, so that the plates can be removed immediately from the exit area of the system for further processing or shipped to the end customer. The waste heat from the preheater can be used to save energy.

![]()

Arrangement of the shot blasting machine and the primer line -

High-temperature roller hearth furnace

Sustainable heating technology

The plates are austentitized in an indirect-fired roller hearth furnace with an inert gas atmosphere. This minimizes the formation of scale on the plate surface and prevents marks on the bottom side. For the heating process, modern low-NOx recuperative burners for minimal emissions and energy-efficient operation are used.

Dividing the furnace into two sections in combination with a special plate operating mode enables excellent temperature uniformity over the entire plate, regardless of its length. The functional package for the high-temperature roller hearth furnace provides the conditions for perfect quenching of the plates in the X-Roll® MultFlex-Quench.

For a “greener” future: SMS provides sustainable heating technology for a carbon neutral production. The high-temperature roller hearth furnace is also available with fully electrical heating system.

![]()

Two-section roller hearth furnace -

X-Roll® MultiFlex-Quench

New cooling standard for plate production

The high degree of flexibility, the broad product portfolio and the excellent flatness results offered by the X-Roll® MultiFlex-Quench are setting new standards for plate production in heat treatment lines. Flexible cooling strategies enable the production of standard and special materials as well as newly developed grades with the highest quality requirements.

![]()

The X-Roll® MultiFlex-Quench is the “heart” of the HTL -

Low-temperature furnace

Tempering of final material properties

The final material properties of the hardened plates are attained in the low-temperature furnace. Like the high-temperature furnace, it is also designed as a roller hearth furnace.

Open firing with in/off-control is used to ensure high convection and uniform temperature conditions in the furnace. Optionally, both can be further increased by adding an exhaust gas recirculation system. This enables extremely precise and uniform temperature setting in the plate, even at the lowest target temperatures. The low-temperature furnace is equipped with low NOx burners and energy-efficient recuperative heat recovery.

For a “greener” future: SMS provides sustainable heating technology for a carbon neutral production. The high-temperature roller hearth furnace is also available with fully electrical heating system.

![]()

Uniform temperature distribution at the furnace exit -

X-Roll® MultiFlex-Leveler

Solution for maximum flexibility

In addition to high-strength material properties, the market nowadays demands excellent flatness and low internal stresses in the plates. The new X-Roll® Multi-Flex-Leveler is setting new standards in terms of final flatness and residual stress distribution in the material.

![]()

Excellent levelling results are ensured by our new X-Roll® MultiFlex-Leveler for cold plate -

High-performance finishing system

Completion and interconnection of processes

The high-performance finishing line, also from SMS group, completes the heat treatment line by interconnecting the various facilities. The robust and low-maintenance roller tables, cooling roller tables, cooling and inspection beds with feed and discharge devices, transfer devices, transport cars, plate storage areas, lifting and centering device, and measuring table for flatness measurements are all designed for a wide range of applications.

The contribution these facilities make to the working process is often underestimated. Sophisticated temperature management of the plates on the different roller table areas and the cooling be is indispensable when producing special steel grades with extremely demanding qualities.

Surface-friendly, reliable, noise-reduced transport and the integration of the associated sensors in protected areas are ensured. The fluid power simulation therefore guarantees an intelligent, cost-effective foundation design. The optimal airflow in the cooling bed area ensures an evenly down cooling process of the plates.

![]()

Finishing line equipment, such as roller tables and cooling and cooling roller tables complete the heat treatment line -

X-Roll® MultiFlex-Turnover Device

Silent and surface friendly heavy plate handling

Plate turnover devices are part of the equipment in heavy plate finishing lines. Our innovative X-Roll® MultiFlex-Turnover device is characterized by low-noise operation, surface-friendly handling of plates and by the expansion of the operating area.

![]()

Turning arms flexibly adapted to the respective plate thickness -

Water treatment plant

Optimally adapted to the heat treatment process

Another factor in the successful production of tempered plate is the water treatment plant. In addition to the water quality, the control of the water pumps is an important part of the automation. The water quantities, calculated in the SMS group cooling model are transferred via an interface to the automation system of the water treatment plant.

The pressure pumps in the water treatment system are frequency-controlled. The pump curves and various operating values are saved in the SMS group cooling model, which not only calculates the required water throughput but also the speed and time required to operate the pumps with the required output. Control of the bypass values is perfectly aligned with the cooling process.

With this features, the water treatment plant is optimally adapted to the process of heat treatment and thus supports the achievement of the high final product quality.

![]()

Frequency controlled water pumps

Services for your plant

Sorry, there are no results for the search term.