Expert chock maintenance and repair

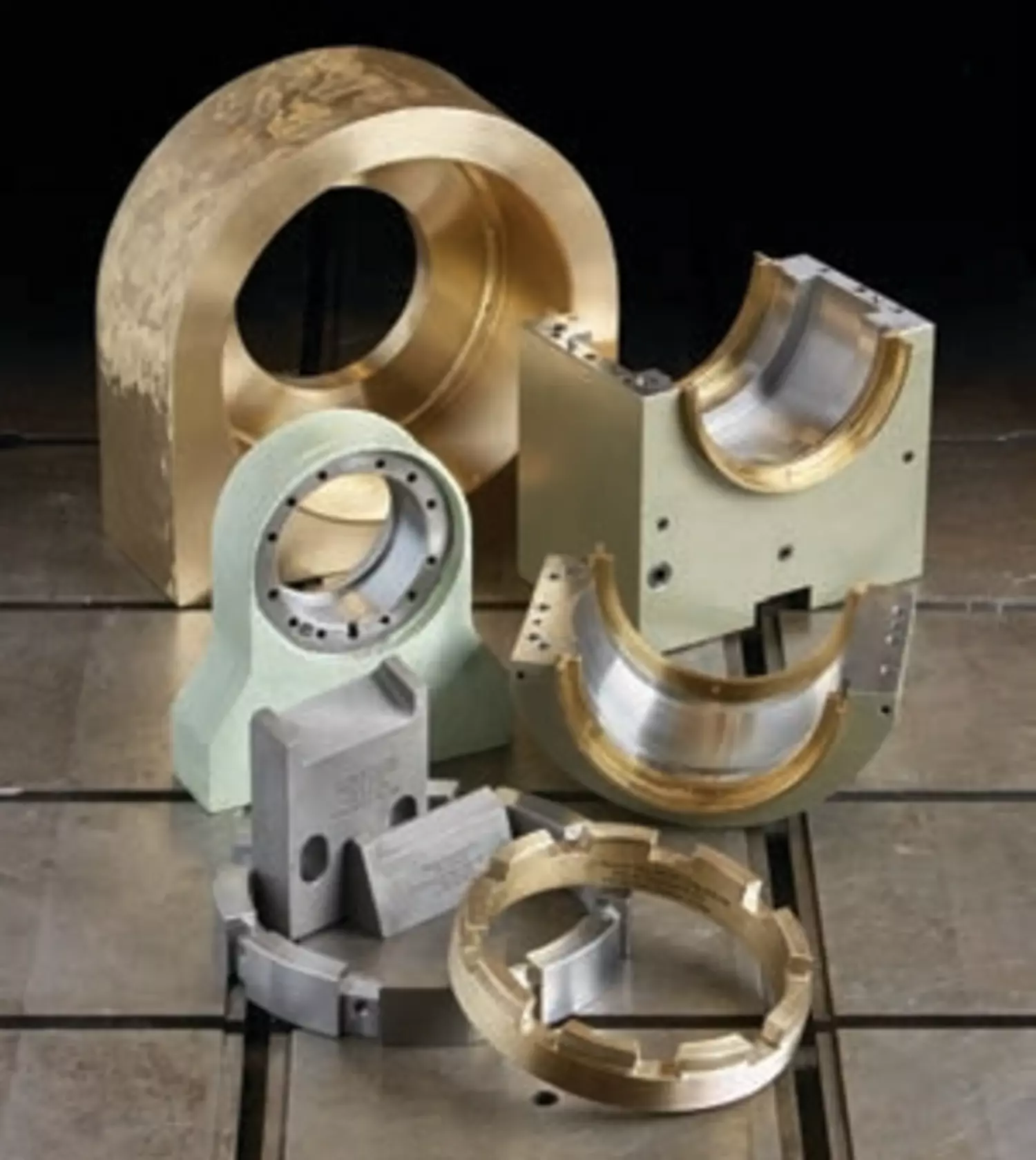

Using our skill, experience, technology and a disciplined process, SMS group expertly repairs chocks used in metals production. As part of our repair process, we thoroughly clean and inspect incoming chocks and document inspection findings. Chocks are then carefully disassembled to ensure components aren’t damaged and parts are thoroughly cleaned. Using precision instruments, our skilled machinists inspect critical dimensions, develop a plan to repair the chock in the best, most cost-effective way possible and prepare a detailed report of the damage and recommended repairs for customer review and approval.

Our thorough repair process includes: premachining surfaces to ensure quality welds; expert welding; thermal spray repair options; stress relieving; and precise finish machining to ensure proper contact surfaces. To ensure top performance, bore diameters are verified and the width of shim liners is set. Final steps in the refurbishment process are inspection; deburring and sanding; cleaning and painting; careful reassembly, including bearing load zone rotation, and packing for shipping to ensure chocks arrive in perfect condition.

Our rigorous repair process pays off. Chocks we have refurbished are returned in as-new or better-thannew condition, regularly providing longer service runs with less down-time. Our innovative processes and manufacturing techniques reduce long-term maintenance costs. Our technical modifications improve reliability and performance.

Precise machining ensures chock reliability in the field

New chocks have long service lives and reduced downtime

Durable new chocks

Using our extensive experience repairing and maintaining chocks and our precision machining equipment, we build new chocks and associated assembly parts from castings, forgings and plate. Experienced craftsmen, know-how and rigorous procedures insure that chocks we build meet or exceed OEM requirements and have long service lives.

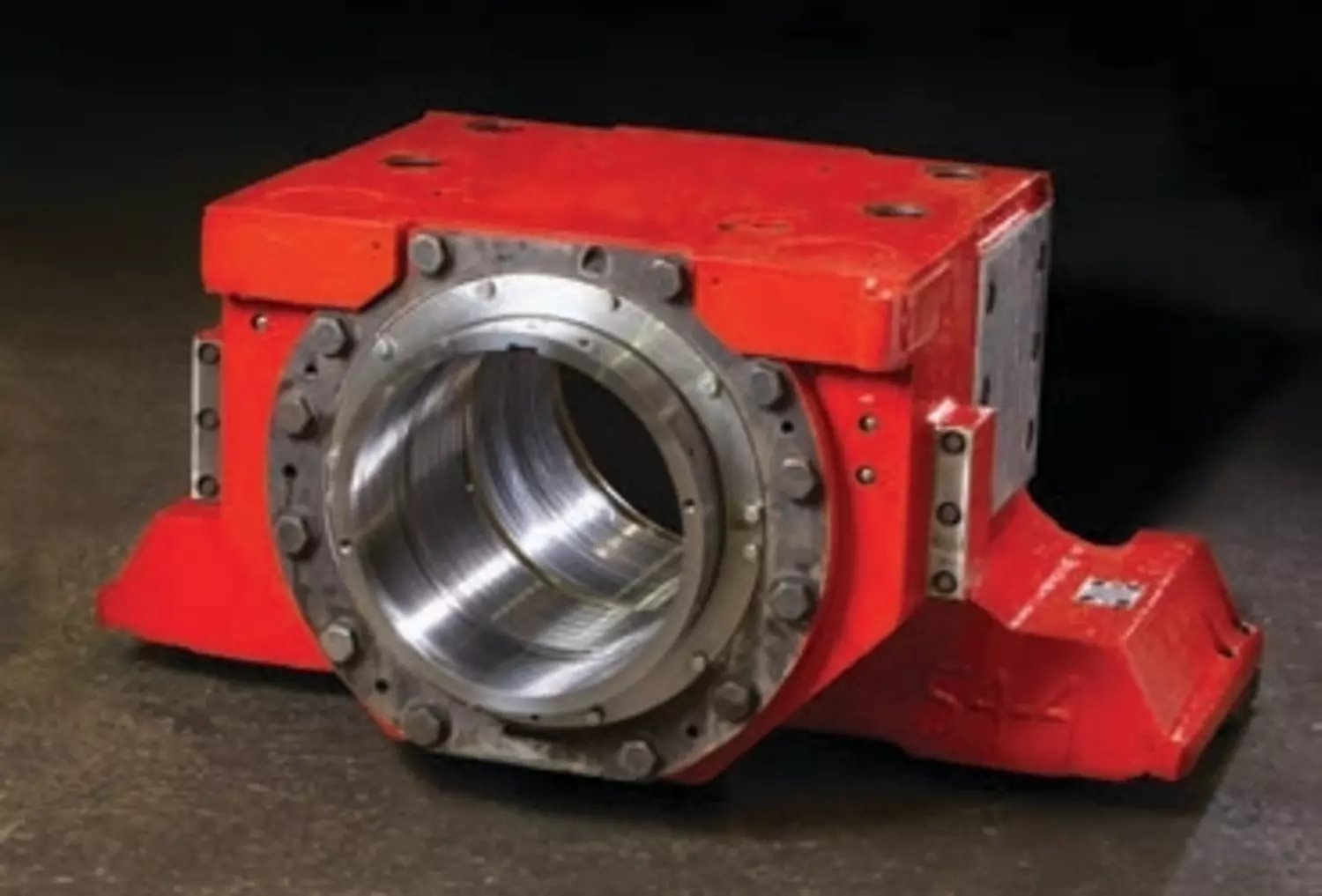

Quality bearing housings and expert repair

In addition to chocks, we also repair, refurbish and build new single-piece, water-cooled and splitbearing housings for rolling mills and continuous casters. To insure top quality, all new and refurbished water cooled housings are pressure and flow tested to ensure they are leak-free and meet their designed cooling capability. Water capacity is also measured and all critical testing statistics are recorded. To improve housing performance, we also offer a chroming program that has been proven to extend housing bore life by as much as 400%.

Repair-build services, textured tread-plate rolls

We also provide a wide range of repair services and build parts, from short product runs to large quantity orders, for ferrous and non-ferrous metals producers. For example, we produce jackshafts and nuts, produce and repair rolls and refurbish side trimmers. We are one of a few producers of specialized textured tread-plate rolls, and our proprietary method allows us to produce them faster and at a lower cost than other producers. With our method, we can also increase roll life up to five times normal because there are fewer grinds between re-texturing. To learn more about how SMS group can keep your chocks and bearing housings performing reliably at peak efficiency, call us at +1-412-231-1200.

Tread-plate rolls made with our proprietary method last longer

New single-piece, water-cooled and split bearing housings