Understanding operational requirements and challenges

The distribution of electricity and resources for production processes in a steelmaking plant relies on several complex networks or grids for different resources, each consisting of several sources, loads, pipes, metering instruments, and other devices and equipment. In some cases, the piping or cabling for each grid can be as long as 50 kilometers, which, naturally, can create real challenges in detecting leaks, malfunctions, and misuses across each of the resources.

Managing a large number of distribution networks, which often exceed 100, can be complex due to contracts that steel mills have with electric, gas, and utility companies. These typically include clauses requiring short-term consumption forecasts with tight tolerances, which, given the ever-changing production conditions and demands, are a real challenge to predict.

Other management factors that operators face include the rapid detection and location of gas or liquid leaks, detecting and correcting instrument malfunctions, and forecasting load and consumption to avoid contractual or technical bottlenecks. Not to mention being properly prepared in the case of production interruptions due to resource shortage.

Real-time monitoring for anomalies and leaks

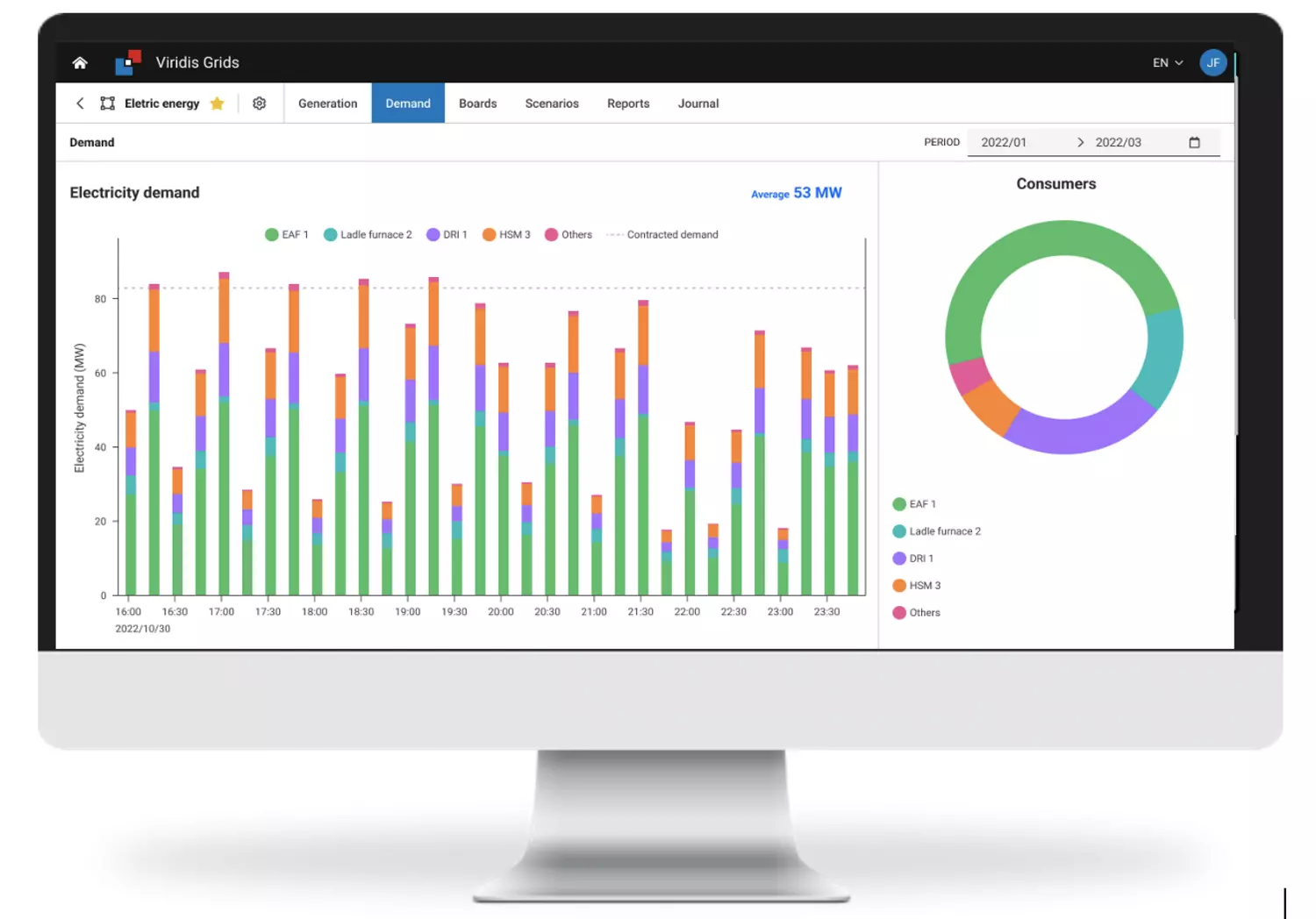

Viridis Grids provides assessments of energy resource generators and consumers and the predictability of availability and energy flows, the evaluation of the possible energy decisions and of the energy dispatch infrastructure to confirm room for maneuver, as well as the optimization and assessment of the frequency and impact of leakage events in specific energy resource grids. The results provide reports detailing the current situation, process performance, and a list of possible decisions in the energy grids together with an estimation of the benefits and savings from reduced leakage, reduced instrument malfunctions, predictability of energy resource availability, and reduced waste.

The lack of predictability in terms of resource demand, leakages, and instrument malfunctions presents a series of challenges. Consequently, network operations need to be improved. Viridis Grids provides a solution that offers improved demand predictability. The software allows you to predict the generation levels of each steelmaking gas, taking different operating conditions into account. In addition, the consumption and energy demand of each consumer can be modeled and predicted under varying operating conditions. It automatically matches measurements in hierarchies, buses, rings, and other configurations to identify faulty situations and alert operators immediately. It simulates demand for each network based on AI models, production schedules, and the order sequence of individual assets. Loads and consumption levels are forecast to avoid contractual or technical overruns. In addition, Viridis Grids delivers forecasts to avoid production interruptions due to resource shortages. Meter malfunctions are detected, and the occurrence and location of power, gas, and liquid leaks are determined. The requirement for Viridis Grids is that the primary instrumentation is already in place.

Efficient meter grid balancing

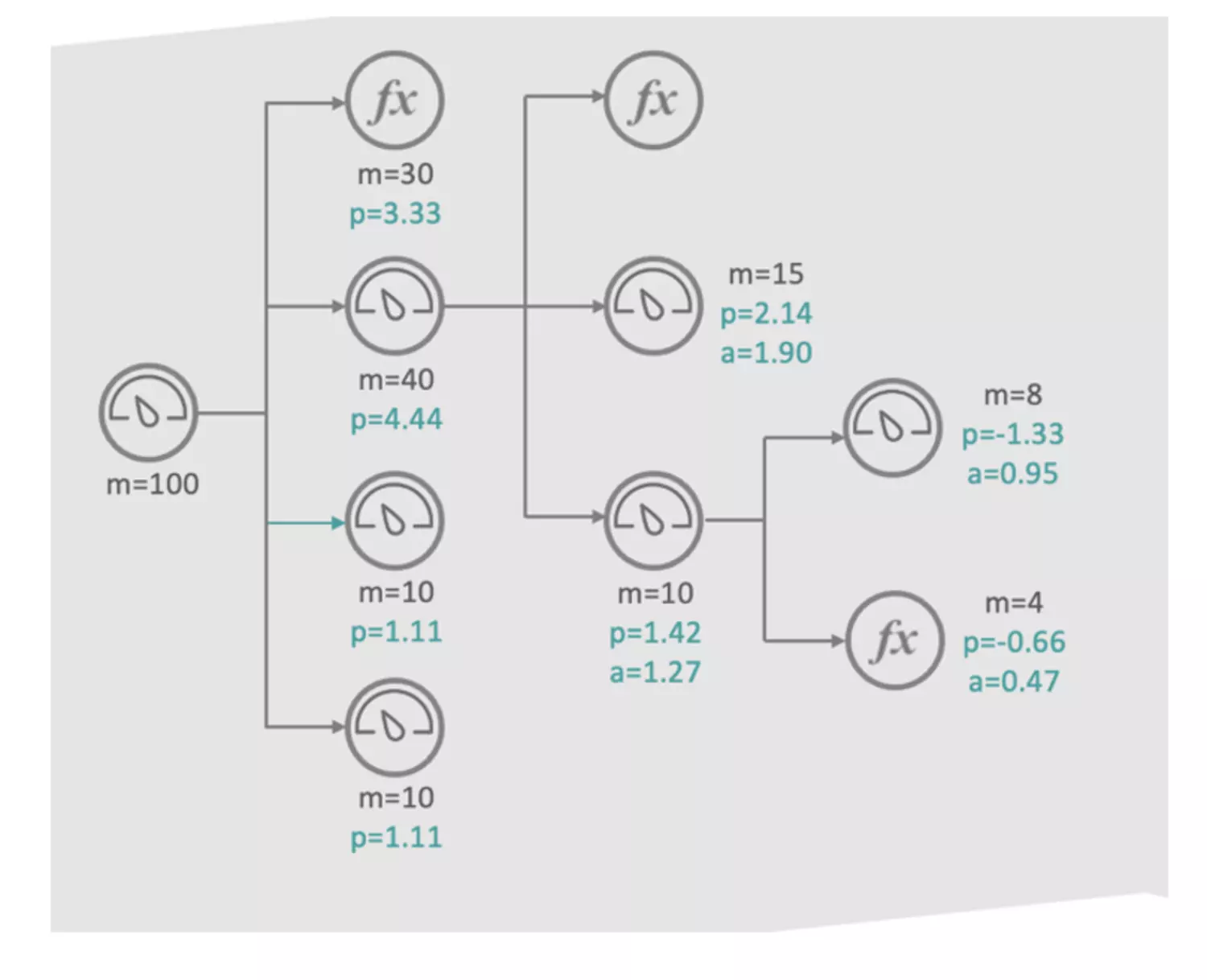

Within the software, meters can be organized hierarchically, providing for explicit balancing relations between a parent meter and its children. Unbalanced relations between a parent meter and its children can prompt alarms that point to leaks or measurement errors. In modeling meter grids, any differences between a parent meter and its children may be balanced by proportionally allocating those differences to the actual measurements. Usually, a boundary meter or a higher accuracy parent meter within the hierarchy is considered the “source of truth” for balancing. Balancing meter grids is a necessary step for closing energy and resource costs.

Energy forecasting - Viridis Grids use case

Predictability of consumption is key to the proper distribution of energy and utilities and is often tied to production and sequence plans, which determine operations in the short- and long-term. Opportunities to optimize energy contracts frequently depend on proper consumption forecasting. In Viridis, models can be configured to predict energy and utility consumption in different time horizons.

Predictions include demand, often a key driver for contracts relating to electricity, natural gas, and gases of the air. The predictions are based on simulations of production plans and sequenced orders.

Let us now consider a use case with the following setup:

- Production line: Coke ovens, sinter plant, blast furnace, BOFs, EAF, continuous casting, hot and cold rolling.

- Capacity: 5.8 million t per year.

One of the difficulties we face is dealing with the problem of uncertain and vague demand and resource availability. In order to overcome this challenge, real-time predictions for consumption and generation have been put in place for all distribution grids. Moreover, the system has been enhanced with the ability to detect abnormal behavior in real-time, which includes possible leaks. By implementing these solutions, multiple benefits were achieved, such as saving electricity and fluids, detecting leaks, and enhancing grid and instrumentation management.

Taking resource consumption to the next level

Viridis Grids offers several benefits at the product level. Users benefit from reduced financial losses due to resource wastage, as leaks are detected at the earliest possible stage. There are also fewer distribution problems due to overloads or lack of resources. Faster detection of instrument failures is provided, as well as fewer overload-related contractual penalties. The implementation time is 4 to 6 months with an expected return of the virtual elimination of energy waste due to leaks. Payback is expected within 6 to 12 months.