Whether it’s extrusion billets, slabs, strips, profiles or tubes: SMS group supplies cost-effective, flexible continuous casting plants for all types of copper and copper alloys. Over the past 60 years we have refined our expertise in plant engineering for all conventional casting processes. Today the traditional SMS group brand, with over 550 continuous casting plants built worldwide, still ranks as a market and technology leader.

-

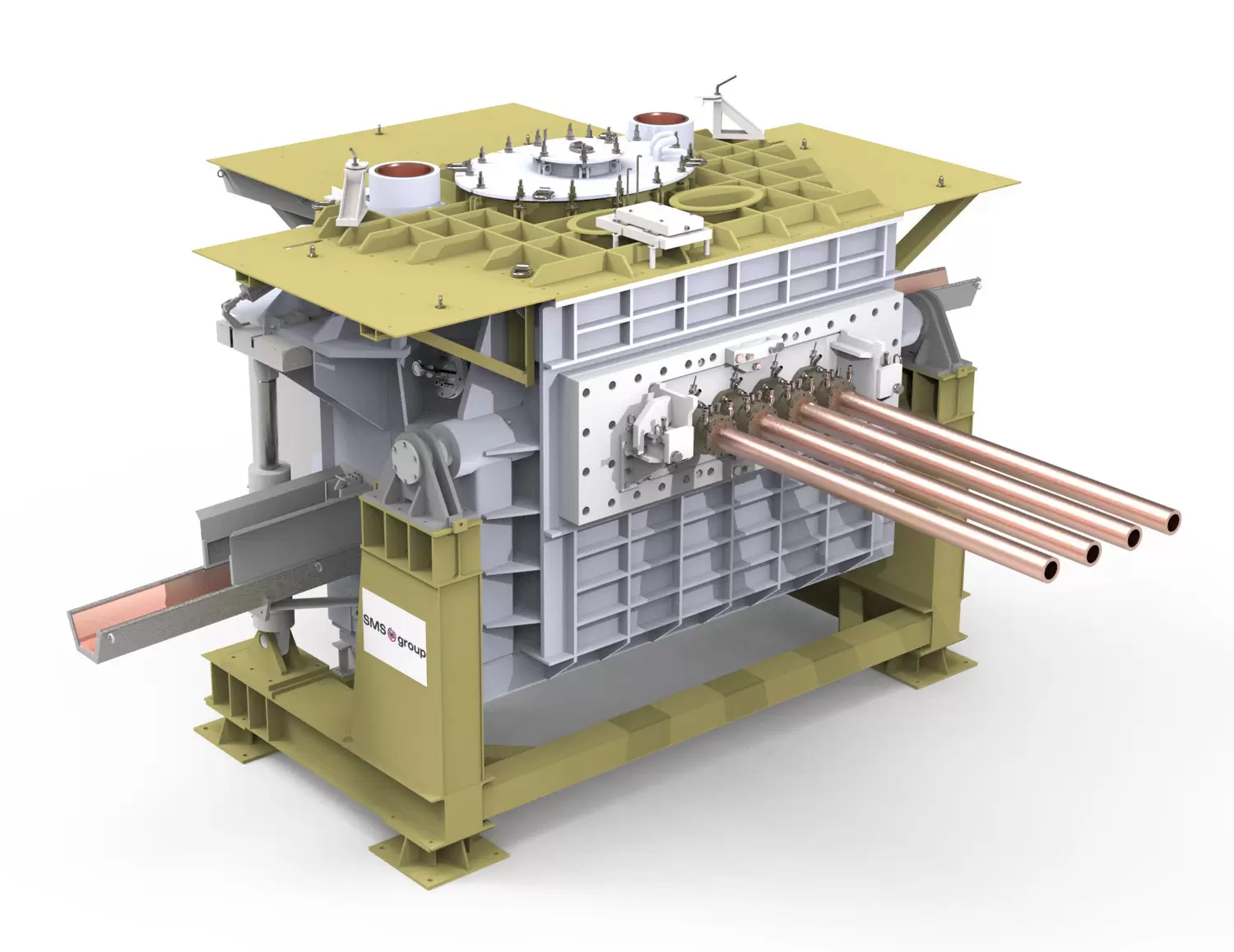

Vertical continuous casting plants for billets and slabs

Main dataWhen it comes to producing slabs and extrusion billets in large volumes, vertical continuous casting plants from SMS group are the ideal solution. These plants achieve an annual capacity of up to 150,000 t of copper or brass products. They are especially attractive to companies that require the highest product quality at the greatest possible capacity levels.

This guarantees customer high productivity levels with low production costs. Whether it's slabs or extrusion billets made from copper or brass – SMS group technology delivers maximum, consistent product quality. Continuous further development of this type of plant means minimal maintenance is required. What's more, SMS group has continuously refined the plant's user-friendliness.

![]()

-

Vertical semi-continuous casting plants for billets and slabs

Main dataFrequently changing casting schedules require top plant flexibility. That’s exactly what you get from these plants. They come with up to 6 strands and an annual output of as much as 120,000 t. You can cast lengths of between 3 and 12 meters – with slab widths reaching 1,300 mm and billet diameters of up to 450 mm. Our semi-continuous casting plants handle a wide range of copper alloys as well as all copper grades. Simply adjust the solidification conditions to the requirements of your copper alloy. This mainly concerns the cooling rate.

![]()

-

Vertical continuous casting plants for precision sections

Great synergy between horizontal and vertical casting

Main dataIt's the perfect combination to fit your wants and needs: the benefits of both horizontal and vertical casting in our precision casting plants. The synergy between these two systems means you can manufacture products with small and medium dimensions in uniform quality and excellent dimensional tolerances. This stock is particularly suitable for further processing on automatic lathes.

![]()

-

Horizontal continuous casting plants for extrusion billets

Flexible billet production from a variety of copper alloys

Main dataYou can rely on our horizontal continuous casters for extrusion billets to achieve top productivity and product quality. These machines cast a variety of copper alloys – such as brass with and without lead, specialty brasses, copper-nickel, and DHP copper. Due to extensive automation, they require little manpower. Furthermore, our casters are highly flexible in terms of production capacity. All this makes horizontal continuous casting plants from SMS an attractive option. Here you can choose between one and up to four strands. Out of these factors evolves an annual capacity of over 100,000 t per year.

![]()

-

Horizontal continuous casting plants for strips

Maximum reliability, productivity and precision

Main dataTogether with our Technica brand, SMS group is the pioneer in wide-strip continuous casting plants. We have banked a wealth of experience with over 100 reference projects. These horizontal continuous casters produce strips 10 to 20 mm thick and up to 1,050 mm wide. Included among the materials they can handle are bronze, brass, nickel-silver, copper-nickel, aluminum-tin and other alloys. We complete your casting plant with inline milling machines, shears, strip upcoilers, and strip bending machines.

![]()

-

Horizontal continuous casting plants for tubes and profiles

Flexible and cost-effective production

Main dataOur continuous casting plants are inherently flexible enough to cast various types of cross sections – for example tubes, profiles, and wire rod. That means you can process typical alloys such as brass, copper, bronze, copper-nickel, nickel-silver, and other precious metals.

![]()

SMS group email service

Our promise to you: this is not just another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

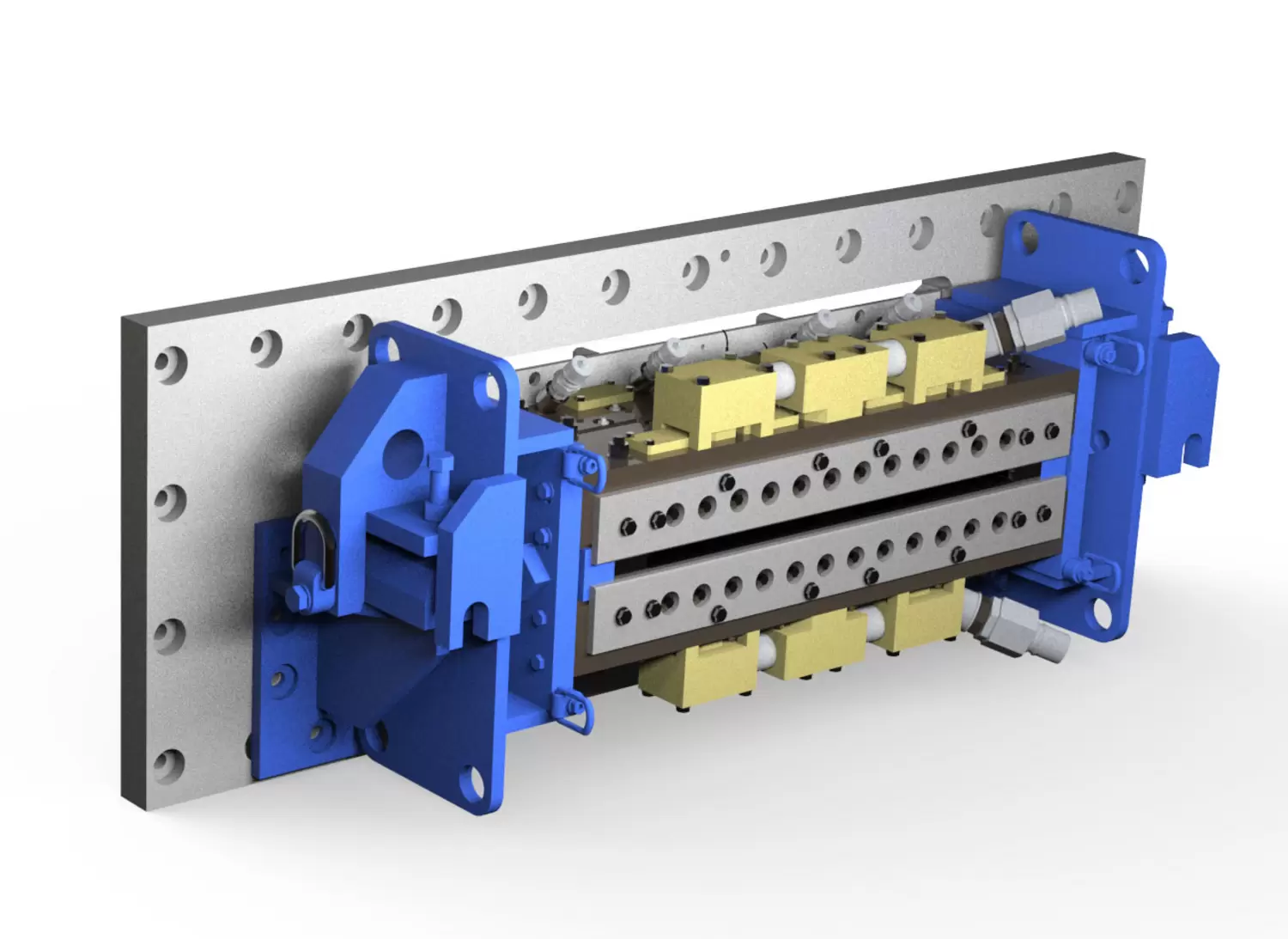

Resonance mold

Highest accuracy in vertical casting

The new developed oscillating table is guided with leaf spring packages. This ensures highest accuracy regarding the oscillation and irregular movements caused by torsions are completely eliminated. Furthermore these guides are maintenance-free.

![]()

-

Strip mold

Optimized solidification of cast strips

Due to an optimized cooler concept the contact area between the graphite die and solidification area could be increased. Furthermore the contact conditions are nearly independent of the temperature distribution because the new designed cooler plates allow a certain thermal expansion of the graphite die which minimizes the so-called “cooler-breathing-effect” significantly.

![]()

-

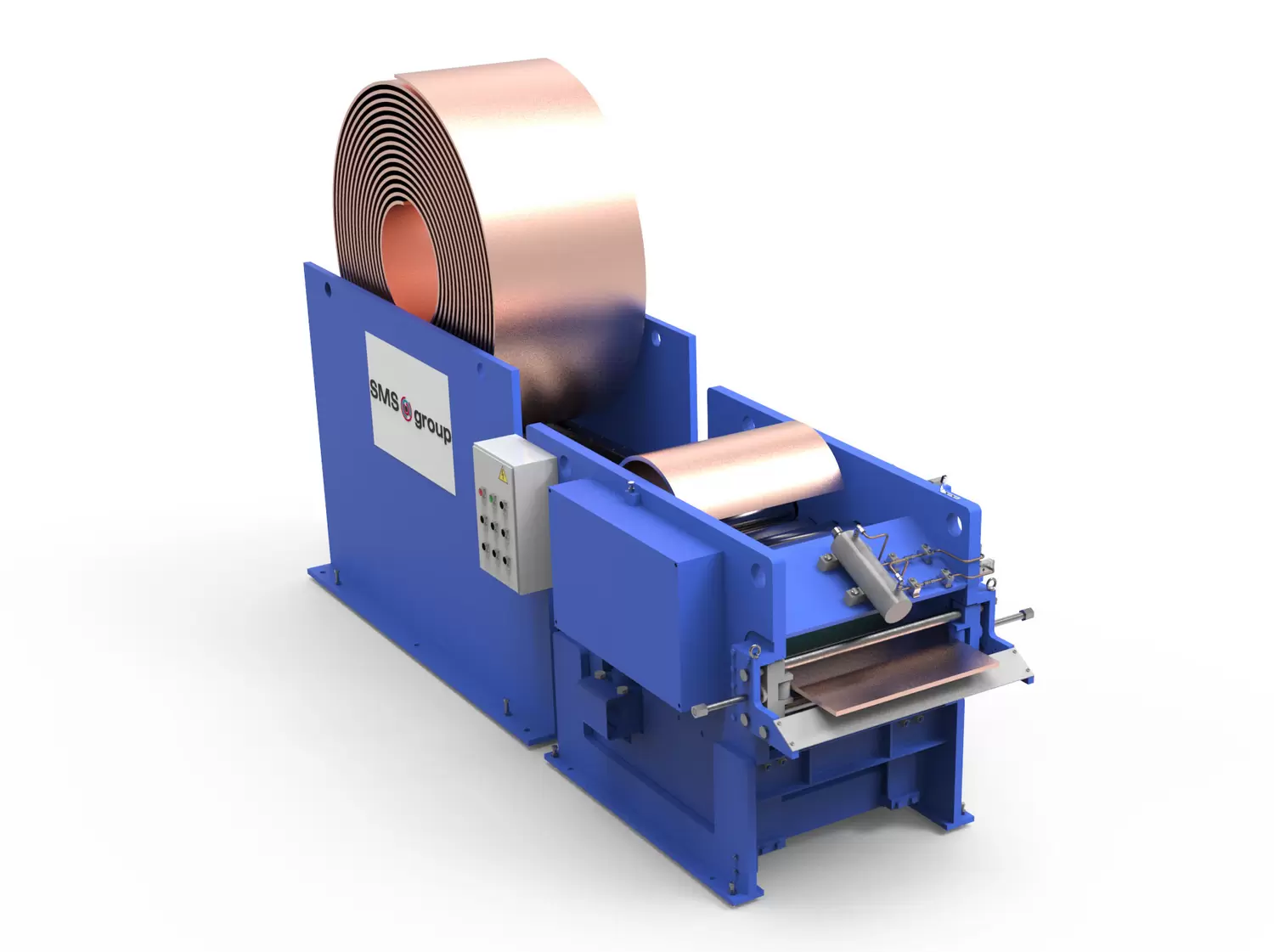

Stationary strip coiler

Higher coil weights

The coiler is permanently driven. The coiling speed is synchronized with the strip casting speed. Therefore the coiler can be directly installed to the foundation. The influence of the coil weight to the accuracy of the strip speed is completely eliminated allowing higher coil weights. Additionally the typical rail-wheel-tracks are also eliminated meaning less maintenance.

![]()

-

Automatic cooling water distribution

Constant cooling conditions

Multiple cooling zones within the cooler in connection with our high precision drive of the withdrawal unit ensure a very homogenous solidification over the entire cast cross section. Furthermore: The cooling water conditions are held constant due to automatic regulation of all cooling water flows.

-

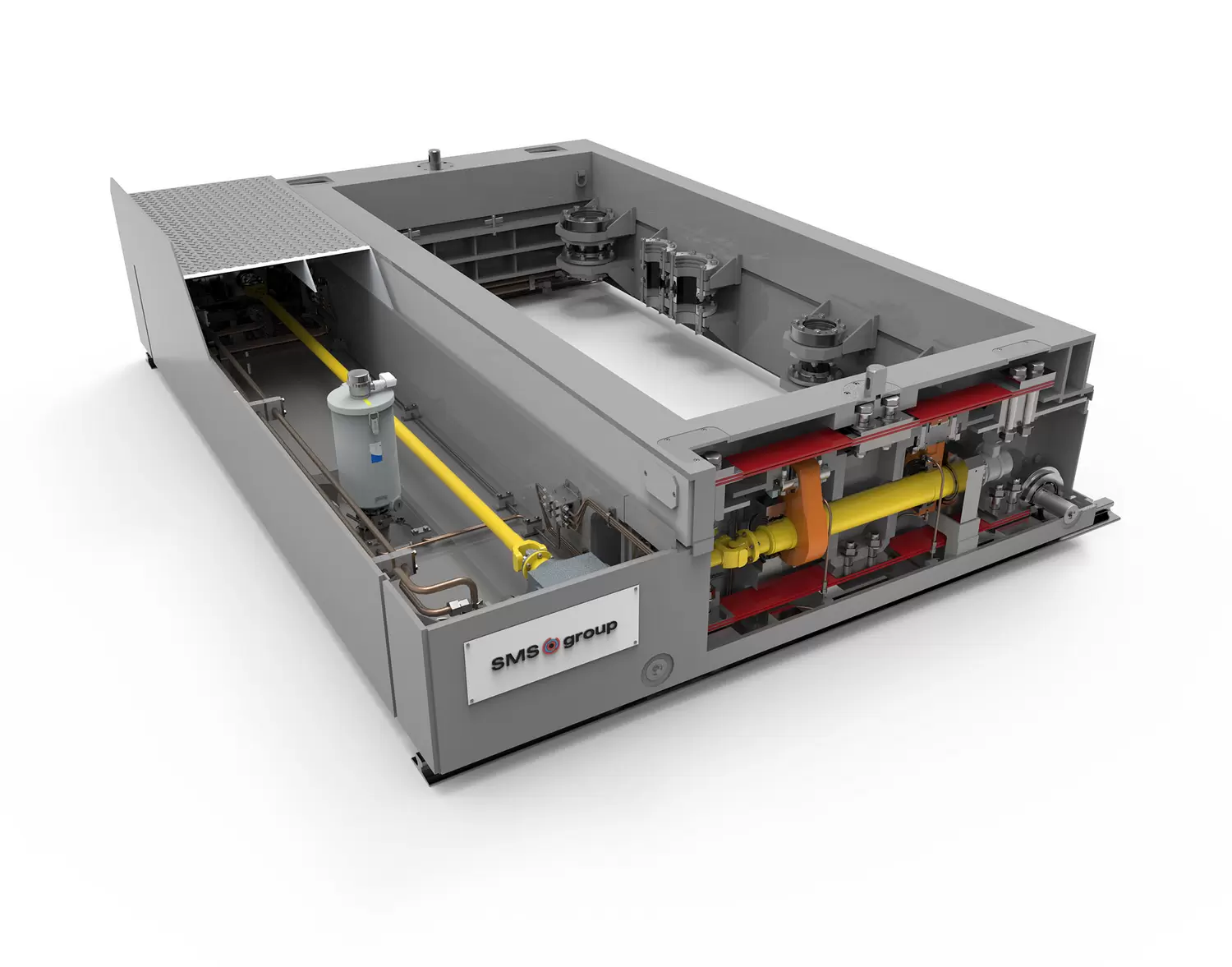

Pressure-controlled multi-chamber holding furnace

Improved efficiency in horizontal continuous casting

Exceptionally effective in our horizontal continuous casting plants is the SMS pressure controlled multi-chamber holding furnace. It comprises a casting, a pressure and a refilling chamber which are connected to each other. As a result, the metallostatic pressure above the mould remains constant and any bath turbulence during refilling is avoided. Since the melt is protected from atmospheric conditions, the amount of slag formation is low.

![]()

-

Control and drive technology

Control and drive technology for horizontal casters

COMPUTOCAST®

Based on most modern measuring methods in combination with our proven process control COMPUTOCAST® all-important casting parameters are permanently controlled and user-friendly monitored.

![]()