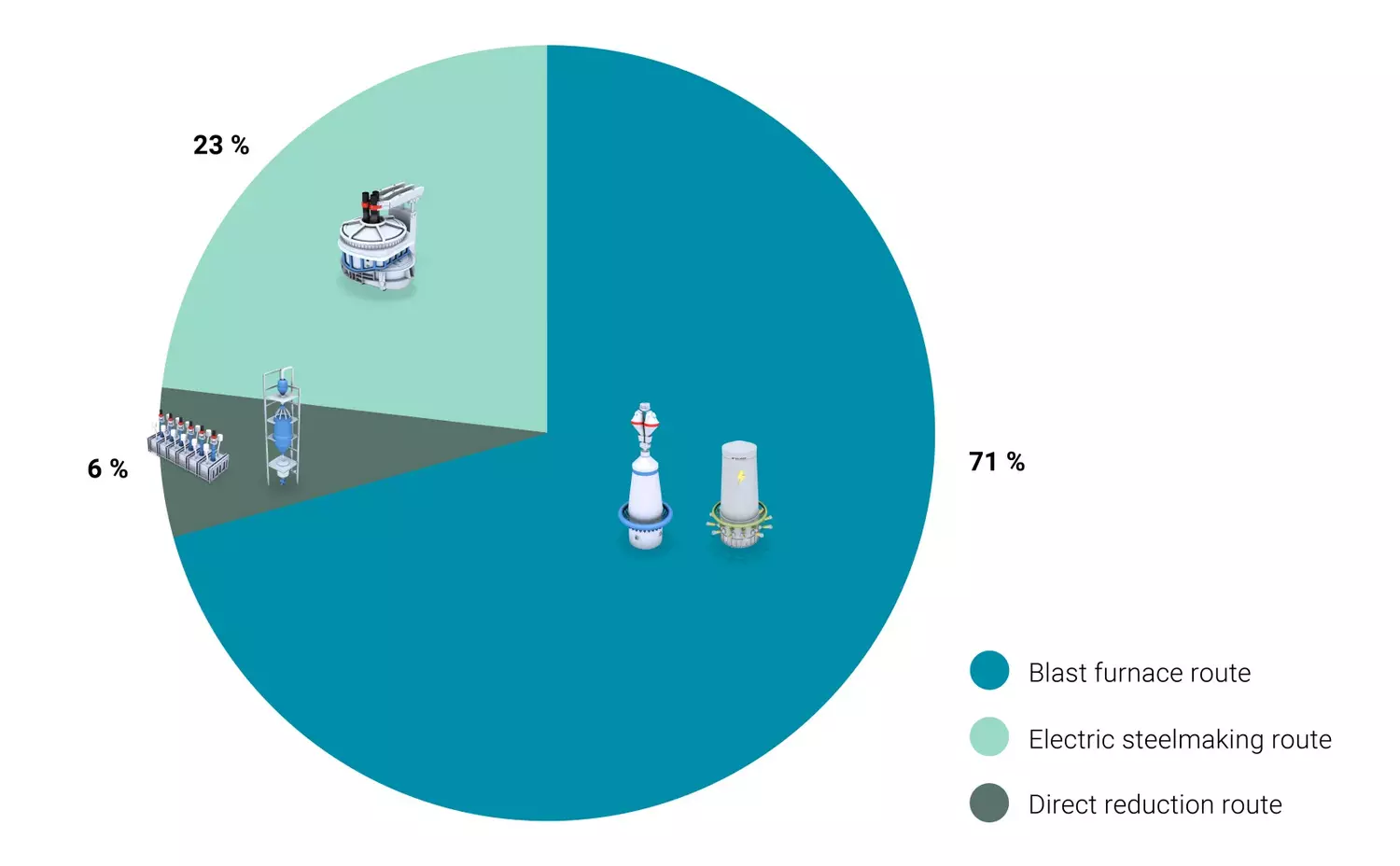

Essentially, there are three major process routes in iron and steel production: the conventional blast furnace route and direct reduction process within primary steelmaking and the secondary electric steelmaking process. Today, around 71 % of global steel production is done via the primary blast furnace route and 6 % in direct reduction processes. Secondary steelmaking via electric arc furnaces accounts for around 23 %.

Blast furnace iron making

Steel consists of 90 % iron. In most cases, pig iron is therefore first made from iron ore in the blast furnace (BF) through the reducing action of carbon (provided as coke) at a high temperature. The blast furnace operates continuously, with raw materials being charged from the top and molten iron and slag being tapped from the bottom. In a second step, this pig iron is further purified in a basic oxygen furnace, also called converter. However, this entire process produces gases that are harmful to the climate, mainly carbon dioxide (CO2). Around 1.8 metric tons of CO2 emissions are generated per ton of crude steel. This is roughly the same amount of CO2 produced by a single commuter traveling 8,100 kilometers per year.

Most of the CO2 is produced in a chemical process that takes place in the blast furnace. It is not the heat that turns iron ore into iron. Rather, the oxygen in the iron ore has to be split off. Coke produced from coal in coking plants is usually used for this purpose. It is heated with hot air in the lower part of the blast furnace and gasifies with the oxygen content of the air to form the reducing gas carbon monoxide. The gas rises to the top and binds the oxygen contained in the iron ore, converting it to carbon dioxide (CO2). Around 85 % of the CO2 emissions occurring in the entire steelmaking process are currently generated in the blast furnace.

Saving of 60% of CO2 emissions by modernization of the blast furnace

Despite its carbon-intensive nature, the blast furnace process remains crucial in the steel industry due to its high production capacity and ability to handle various types of iron ores. Therefore, ongoing advancements, such as the Blue Blast Furnace and EASyMelt technology, aim to modernize blast furnaces and reduce greenhouse gas emissions, ensuring a greener and more sustainable future for steel production.

At the heart of the Blue Blast Furnace and EASyMelt technology is the utilization of syngas, a gas composed primarily of carbon monoxide and hydrogen. Syngas acts as a reducing agent, replacing the use of coke in the blast furnace. By injecting syngas through a new bustle pipe at the lower shaft portion of the furnace, emission reductions of around 30% can be achieved.

By further upgrading the blast furnace with the EASyMelt concept, emission savings of above 60% can be reached. The solution can be realized in a low-cost step-wise approach of implementing several technological elements that work together to net-zero ironmaking, such the shaft injection of reducing gas, plasma-based superheating, and carbon capture for storage or utilization. EASyMelt is an electrified direct reduction and melting process, using a minor quantity of coke to entirely replace the traditional hot blast with gases like coke oven gas, natural gas, hydrogen, and ammonia.

Electric steelmaking route

The second largest steel production route is the electric arc furnace (EAF) process. The EAF uses mostly steel scrap as a raw material instead of iron ore and process it accordingly. Here, the scrap is melted in an electric arc furnace at high temperatures, converting it into high-quality steel products. Graphite electrodes conduct the electric current and generate the arc, which converts the electrical energy into heat of fusion with very good efficiency and high energy density. It offers several advantages, including energy efficiency, flexibility in raw material usage, and reduced greenhouse gas emissions compared to traditional steelmaking methods. Since this process does not require iron ore, virtually no CO2 is produced in the actual process. However, this process requires a great deal of electricity - electricity that in most countries today still comes mainly from fossil sources, like coal or gas. CO2 emissions are therefore generated at an earlier stage.

Considering the emission saving potential of around 90% compared to the blast furnace route, electric steelmaking would be the steelmakers optimal choice for producing green steel. However, EAF steelmaking also faces certain bottlenecks, one major bottleneck being the scrap steel availability and quality. Electric steelmaking heavily rely on scrap steel, and fluctuations in its supply and composition can impact the steelmaking process. It further has limitations in producing specialized steel grades due to the absence of necessary alloying elements in scrap. Due to these limitations, innovative methods are needed to make a significant difference in the climate-neutral steel production and in saving the climate.

Direct reduction route

A major alternative to the blast furnace route is to produce direct reduced iron in a shaft furnace with a reduction gas. The direct reduction process is simple to operate involving only three major units: iron ore reduction, gas preheating and natural gas reforming.

Getting into the details of the process, DRI (direct reduced iron) is produced starting from iron ore pellets, which is reduced by means of a hot reducing gas stream, removing the oxygen from the mineral. The reduction takes place in counter-current shaft furnace, where the material descends by gravity and the hot reducing gas is injected into the heart of the DRI shaft furnace. It is flexible as well as a versatile which can use either natural gas or hydrogen as the reducing gas. The produced DRI will then be fed either in an Open bath furnace (OBF) or Electrical Arc furnaces (EAF) as downstream smelters.

The direct reduction can either be based on natural gas, which already achieves major emission reductions thanks to the higher hydrogen content in natural gas. Or the DR plant can run with renewable hydrogen as the reducing gas, which allows for further CO2 reduction of up to around 65% in a DRI-OBF plant and 95% in a DRI-EAF set-up.

Steelmaking can go green!

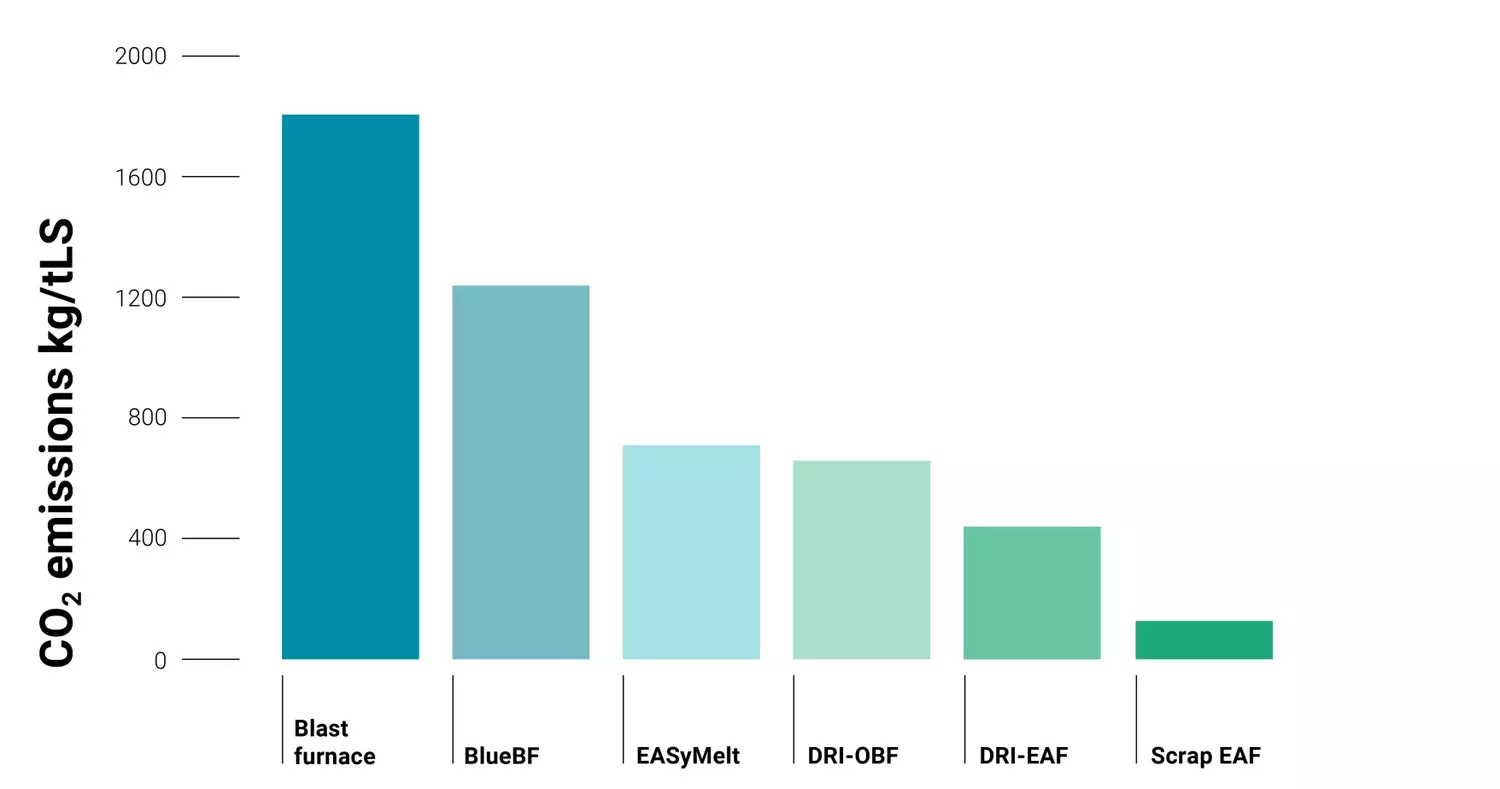

If we look at the graph below we can see the very different CO2 intensity of the different routes from an average of 1,800 kg CO2 per ton of steel for the blast furnace, to about 650 kg for direct reduction, to about 130 kg for the scrap route. Shouldn't all steel producers then immediately switch to the lower-emission routes? Well, there is no one-size-fits-all ‘best’ option. One reason is the extremely high cost of these plants and thus the very long investment cycles. That's why, a large part of future CO2 savings must come from the conversion of existing mills.And the figures also show that existing blast furnaces can be converted in such a way that CO2 emissions can be drastically and rapidly reduced with moderate investment.