Shaping the future – converter steelworks from SMS group

Since the early 1950s, SMS group and its predecessor companies have been using their know-how for highly productive and modern converter steelplants for carbon and stainless steel worldwide. SMS group is one of the leading companies in this market and meets the growing demands of its customers with advanced and reliable mechatronic systems. In cooperation with universities and institutes, eco-friendly and economical solutions are developed that are used worldwide.

The product range is wider than ever. This includes complex BOF and AOD converter steelplants with a high degree of automation and digitalization, as well as new paths in the metallurgical process and modernizations. Our solutions are durable and sustainably reduce maintenance costs. Tailor-made maintenance procedures, customer-specific training programmes and effective spare parts management round off our range of services. SMS group Technical Services is your contact for this: Service packages tailored to your requirements are available worldwide.

The key features are

- High productivity and product quality

- Latest process technologies and superior products

- Project solutions with a fast return-on-investment.

-

Future-oriented stainless steelmaking

What's special about our process lines is that we tailor your plant to your conditions. Included in these considerations are availability of raw materials, infrastructure, and energy supply. The upshot is that you can produce high-quality materials at low cost.

![]()

-

Efficient custom-engineered vacuum converters

We specially develop vacuum converters for producing stainless, acid-resistant, and heat-resistant steel grades as well as highly alloyed special steels, manganese, and chromium alloys, plus medium and low-carbon ferromanganese and ferrochrome.

![]()

-

AOD converter

The AOD converter is key equipment in the stainless steelmaking process: An argon-oxygen mixture is being injected into the molten steel through sidewall-nozzles which provokes a very efficient carbon removal.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

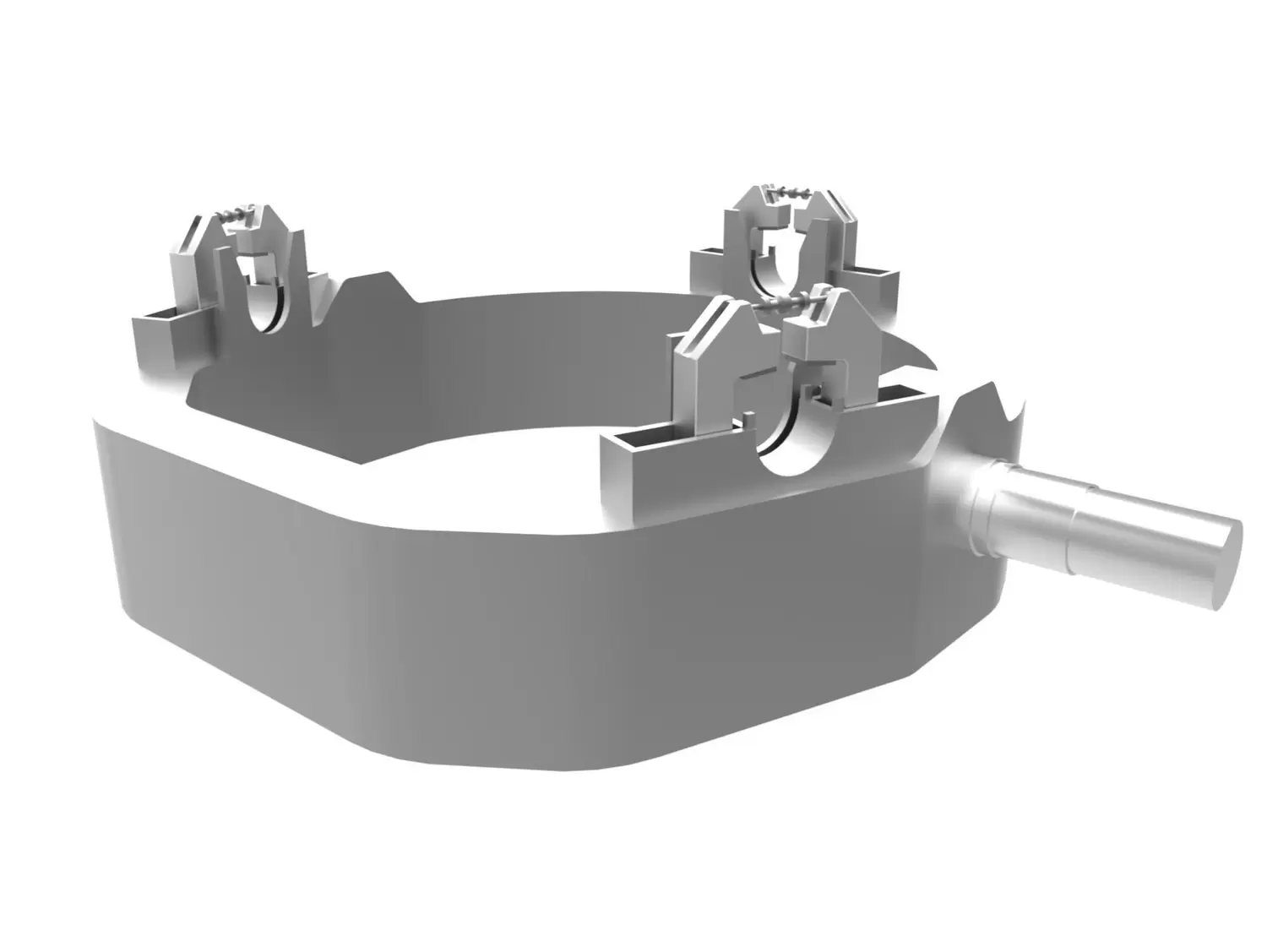

Hydraulic clamping device

The converter vessel is held in the trunnion ring by three clamping elements. Vessel pins, which are welded to the vessel shell, are mounted in support brackets attached to the trunnion ring.

Highlights

- Automated system

- Allows thermal expansion of the vessel in the trunnion ring

- Mechanically secured against unintentional opening

Benefits

- Quick converter exchange with an exchange time ≤ 30min

- Higher safety standard for operators

![]()

Services for this plant

Sorry, there are no results for the search term.

Insights on this plant

Show allDownloads

-

Increased plant availability

-

Increased plant availability

-

Efficient vacuum converter for individual needs

-

Efficient vacuum converter for individual needs

-

Maintenance service

-

Maintenance service

-

Converter Inspection

-

Converter Inspection

-

Low-Voltage Frequency Converter

-

Low-Voltage Frequency Converter

-

Energy-efficient gas cleaning

-

Energy-efficient gas cleaning

-

BOF Process Model

-

BOF Process Model

-

Ladle Management System

-

Ladle Management System

-

Future-proof complete solutions from one source - Electrics and Automation

-

Future-proof complete solutions from one source - Electrics and Automation