Contactless measurement for optimal production processes

TBK in Graz, Austria is SMS group´s center of competence for laser measuring equipment.

TBK has been developing measurement technology solutions for the steel industry since 1986, in particular laser measuring systems based on the light section method. TBK and SMS group have been working closely together since 2004. As a brand of SMS group, TBK offers tailor-made solutions for dimension control and surface analysis of rolled products for the long product plant range, including wire rod, bars, sections, rails, as well as tubes or semi-finished products such as continuous cast billets or blooms. Straightness measuring equipment, especially for rails, and instruments for measuring special profiles and wheels complete the product range.

Location

-

Continuos monitoring of rolling processes

TBK sensors use the light section method. This method allows the entire contour of the product to be examined, regardless of its shape. The sensors are an in-house-develpoment and measure up to 15,000 contours per second. Following the principle of two-dimensional triangulation, a laser line is projected onto the product surface. Diffusely reflected light provides the basis for the acquisition of cross-sections from which relevant information for controlling the rolling process can be generated.

TBK systems are able to calculate the precise cross section of the product using these values. The high-resolution and high measurement density enables the creation of a 3D model of the product, which also recognizes surface defects.![]()

-

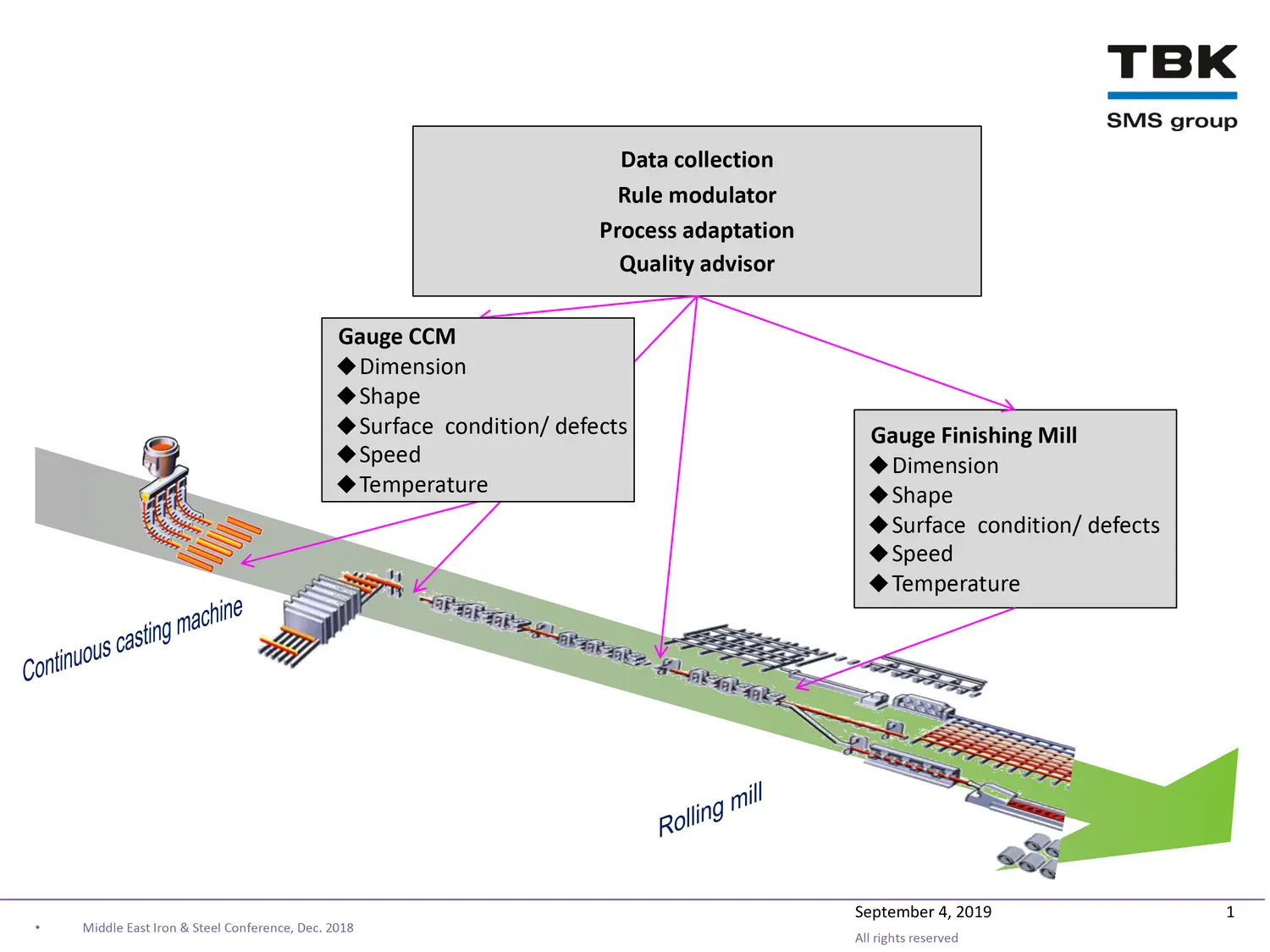

Sophisticated measuring technology ready for Industrie 4.0

Automatic collection of product data is key to digitalization

It is usually plant operators who make decisions regarding production control, and relevant and precise key performance values provide a reliable basis for this. In addition to standard, established values, TBK measurement systems provide a wide product-specific range of dimensional parameters. Tried and tested algorithms that have proven to be effective are used to generate performance values from the measured contour data.

Industrie 4.0 rolling mill

The aim of all mill operators is to maintain stable mill operation with high time utilization and consistent product quality. A fully automated system of production control and data collection is a basic requirement of digitalization. Furthermore, to adjust and adapt the process according to different conditions, process data or production and process data are required in addition to data on the product conditions. The TBK gauge collects data on the condition of the finished product including its geometry, shape, dimensions, surface conditions, and on the temperature or rolling speed.

![]()

Customized solutions

TBK systems can be utilized for the full range of long products including wire rod, bars, tubes, sections, rails and special profiles, as well as continuously cast billets and blooms. Our portfolio also covers the measurement of wheels or rings rolled on a ring rolling machine as well as forged product measurements:

PROgauge

Laser measuring device for profile and rails (in hot and cold condition)

MEERgauge®

Laser measuring system for bars, wire rod and tubes (hot and cold condition)

REBARgauge

Measurement of dimensions and determination of weight per meter for rebars

PROwave

Straightness laser measuring system for rails, sections and tubes and rail waviness

Dimension measurement systems

For billets, bloom, slabs, wheels, and special profiles

SurfTec

Surface defect detection system for sections, rails, bars, wire rod, and tubes

Contact

-

Ralf Kremer

-

Ralf Kremer

+43 316 405574 13TBK Automatisierung und Messtechnik GmbH

Schmiedlstraße 8

8042 Graz

Austria![]()

-

Gernot Scheiflinger

-

Gernot Scheiflinger

+43 316 405574 34TBK Automatisierung und Messtechnik GmbH

Schmiedlstraße 8

8042 Graz

Austria![]()