The market for hot rolled strip is characterized by constantly growing demands on quality and a continuously rising share of newly developed, higher-strength steel grades. Coupled to the condition of having to produce flexibly and cost-effectively, this leads to ever higher requirements on equipment and process technologies. Ensuring high plant availability and high stability of the rolling process are the prerequisites for economical production, in particular when high-strength, thin hot strip is concerned. The technology concept of SMS group, comprising various interlinked modules, offers a broad basis to satisfy all these requirements.

CVC® plus

One example of such a technology module combining mechanical actuators, control systems and process models, is the Profile, Contour and Flatness Control model PCFC®, with the patented CVC®plus work roll bending and shifting system being its most effective profile actuator.

In 1980 already, the basic principle of CVC® (Continuously Variable Crown) was invented to perfectly supplement the established work roll bending system. It allowed work rolls with a special contour to be axially shifted and the resulting roll crown and hence the roll gap profile to be continuously influenced. Parallel to the first use in practise, a pertaining technological process model (PFC) was developed on the basis of physical-mathematical approaches. This process model calculates, among others, the set values for the CVC® shifting and work roll bending systems.

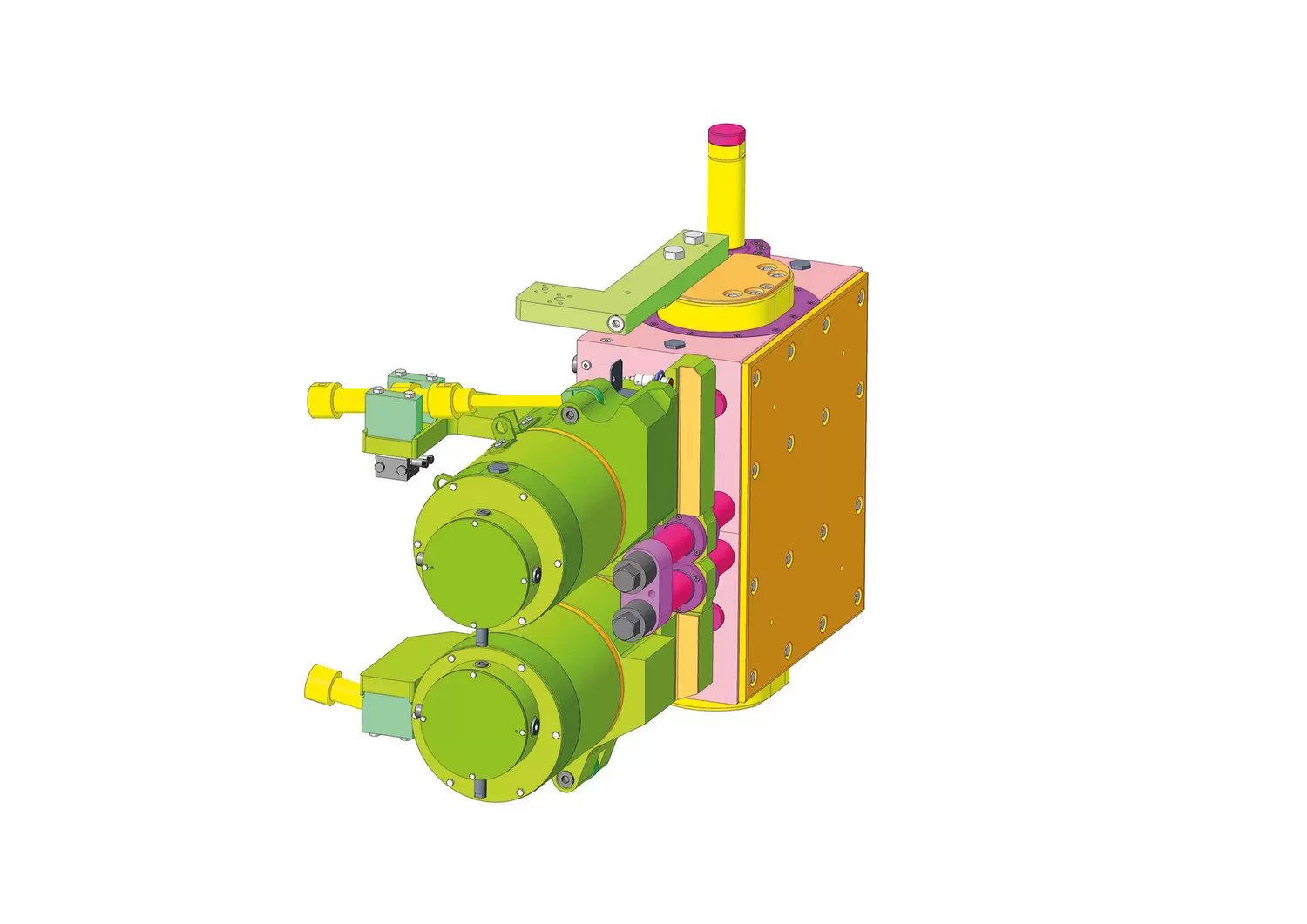

The main mechanical components of this actuator are the CVC® bending and shifting blocks integrated in the finishing stands of hot flat rolling mills, CSP® plants and Steckel mills. In addition to other products, such as hydraulic adjusting system, gear units, gear-type spindles, loopers and coiler mandrels, CVC® blocks belong to the core products SMS group manufactures in its own workshops. Following the invention of the CVC® basic principle in the 1980’s, SMS group equipped its own workshop with all mechanical machine tools required for that purpose.

Succesful product

Within the next few years, the CVC® system was integrated in a large number of various types of hot rolling mills due to its simple and efficient operating principle combined with robust and reliable mechanical equipment. As to the mechanical systems, distinction is made between the so-called longstroke system with movable bending blocks and the short-stroke systems with stationary bending blocks. The type of system to be used depends on the required shifting stroke. Oval-shape pressure hulls allowed the cylindrical bending cylinders so far employed for a shifting stroke of ±100 millimeters in the short-stroke system to be used for an adjustment range of ±150 millimeters, too. The new design, however, required the advancement of the manufacturing processes to make sure the new pressure hull contour was provided with the necessary high surface quality and surface properties. So, new manufacturing methods and processes, including pertaining machines and special tools, were implemented to meet these requirements.

In addition to their different structures, the two CVC® systems come with different numbers of cylinders. Manifold requirements in numerous implementations paired with results from practical experience have led to constant advancement and increased service life. Furthermore, the short-stroke system offers the advantage of integrating the backup roll balancing unit in the fixed block.

Established in the market

Its robust design, the low number of individual parts and less tolerance-related components impacting the window clearance made the short-stroke CVC® system successful on the market. Several plant operators conduct a first inspection about five years after system installation.

All process stages like design and accompanying measures such as FEM analyses, manufacturing and installation work as well as quality control were planned in-house, advanced and optimized to reach product maturity. Also included are, after-assembly in the workshop, all function tests on test facilities specially developed and built for that purpose

Customers see benefits

This led to an extremely reliable product ensuring high plant availability on the one hand and hot rolled strip of extraordinary product quality and close tolerances on the other. And that is the reason why, over the last few years, SMS group has received a constantly rising number of inquiries and orders by customers who want to replace their work roll bending and shifting systems supplied by other suppliers with new short-stroke CVC® systems including the PCFC® Profile, Contour and Flatness Control model.

Fast implementation by local proximity

To enable the experts of SMS group to quickly implement the customer-ordered modernizations and to ensure short delivery times, all trades and processes involved in the product already start to coordinate and cooperate in the sales phase. Apart from this organizational measures, it is the local presence and the cooperation of sales, order handling, development, design, production and service departments at all of SMS group’s locations that support the successful product management of one of the most important actuators in the finishing stands of hot flat rolling mills.