Complete hot and cold processing lines

SMS group offers customized products for manufacturing high-alloy oilfield tubulars. Hot-finished, high-alloy oilfield tubulars can be produced on extrusion lines in the diameter range from 33.4 to 323.9 millimeters. Cold-rolled tubes in the diameter range from 5 to 280 millimeters can be produced on cold pilger mills. In its product portfolio, SMS group has complete hot and cold processing lines. In addition to the core units such as extrusion line or cold pilger mills, machines for billet preparation, pickling and degreasing facilities, and finishing and testing equipment are offered as package solution. Stainless steels or nickel-based alloys are melted in an electric arc furnace or in induction furnaces under the exclusion of air and are further processed in downline plants by Argon-Oxygen Decarburization (AOD) or Vacuum-Oxygen Decarburization (VOD).

The product range of SMS group also includes all the plants for primary and secondary metallurgy for the melting of high-purity stainless steels and nickel-based alloys as well as the necessary casting plants. After casting, the round ingots are rolled to the required billet size or forged on radial forging machines and then peeled on special machines of SMS group. The extrusion line consists essentially of a preheating station, the billet lubrication unit, a vertical piercing or expanding press, a reheating station, the billet lubrication unit, the horizontal extrusion press and the runout section with downline water or air cooling of the extruded tubes. The modern horizontal induction heating lines of the preheating station and the multi-zone heating units of the inductive reheating station come from ISA, another member of SMS group.

Downline of the extrusion press, the tubes have to be quenched in a water tank to achieve their quality levels. In order to avoid distortion and deformed tubes due to the quenching process, water is sprayed selectively and under high pressure onto the tube surface by a water spray system. After extrusion the extruded shells are finished. Necessary machines and equipment such as 10-roller straightener, cut-off facilities, pickling baths or non-destructive testing facilities are integrated into the overall plant by SMS group. After visual inspection, marking and packing, hot-finished process tubes can be delivered directly to the customers for further processing, depending on the application.

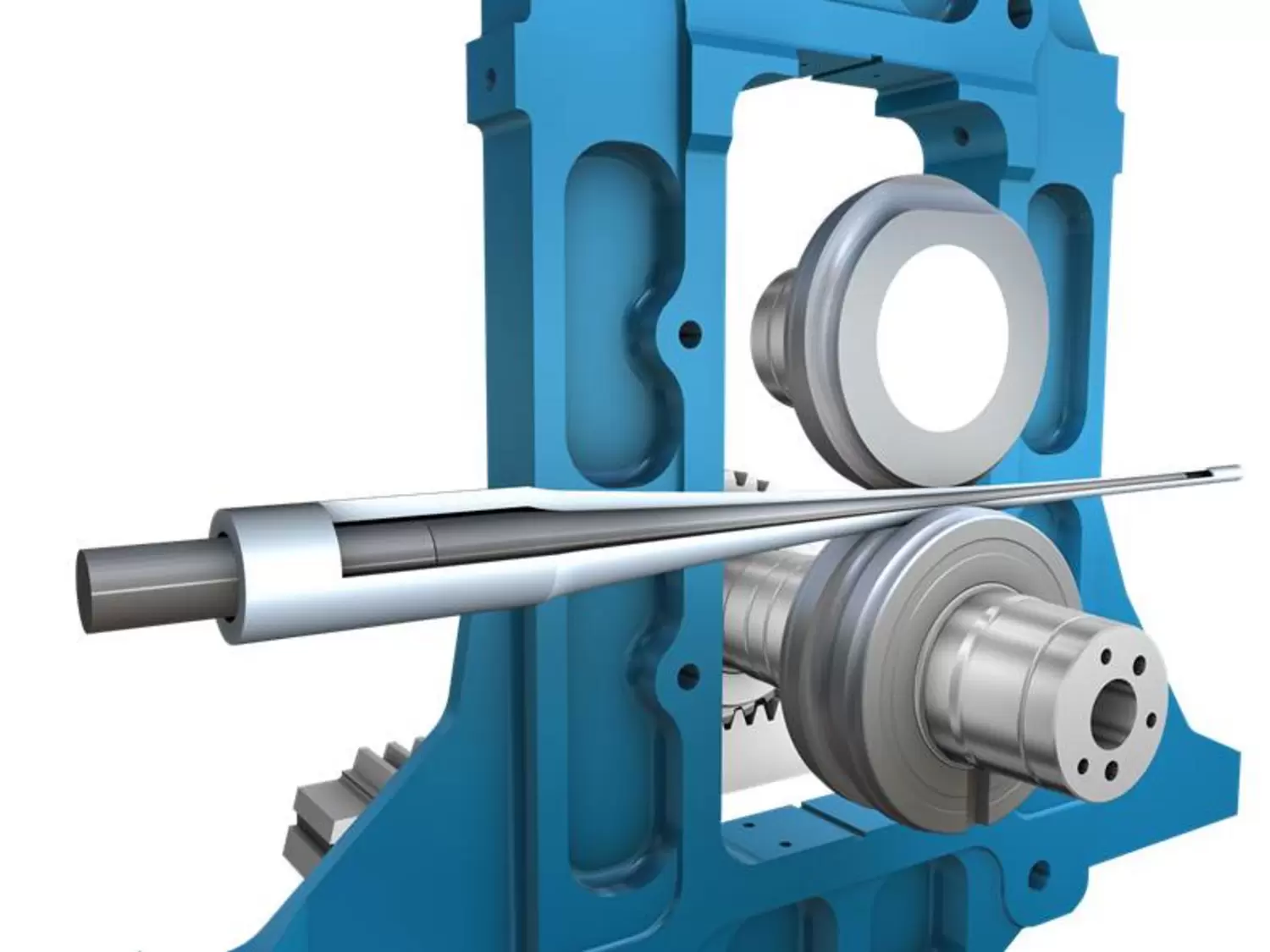

The hot-finished shells are delivered to the pilger shop and further processed on cold pilger mills to produce strain hardened OCTG tubes (Oil Country Tubular Goods) with defined strength properties. After selective cold forming, the oilfield tubulars are no longer annealed and therefore retain a higher strength. The cold pilger line of SMS group consists of a longitudinally oriented cold rolling process with a very high cross-sectional reduction per stroke, and close diameter and wall tolerances. Ring dies and tapered mandrels are used for forming during the cold pilgering process. This process achieves cross-sectional reductions of more than 80 percent in a single working cycle for stainless steel and nickel alloys. The large cross-sectional reduction decreases process costs. The partial radial material flow during cold pilgering also helps to significantly improve the wall thickness eccentricity of the mother tube.

After cold pilgering the tubes are degreased, adjusted and tested. Straighteners, installations for hydrostatic testing and threading machines belong to the scope of supply of SMS group. Other systems and machines are purchased according to the technical specifications of SMS group. After commissioning of the hot and cold production lines, SMS group experts accompany and optimize the start-up of production. Furthermore, SMS group carries out modernizations and plant expansions, such as replacement of components or increases in press force on the steel tube extrusion presses.