What significance does the digital twin have for the manufacturing industry?

The term \"digital twin\" refers to the definition by Grieves and Vickers in the year 2002. In 2016 this definition was updated to the following formulation:

“The Digital Twin is a set of virtual information constructs that fully describes the potential or actual physical product from micro atomic level to macro geometrical level. As its optimum, any information that could be obtained inspecting a physical manufactured product can be obtained from its Digital Twin.” [Grieves and J. Vickers (2016). Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems.]

What does that mean in practice?

The digital twin is a virtual representation of a material or immaterial object of the real world that not necessarily exists, e.g., in the design phase of a machine. But it is more than a real-world-replica. As the concept of digital twins is universal, it can thus be applied to almost everything: to machines, tools, processes, human capital, production, and quality KPI, and so on. With a highly used case-driven design, the digital twin foremost delivers all required data, functionalities, and information to accomplish the given task and fulfill its use case-related purposes. Nevertheless, it is mandatory that the concept needs at least three elements: an object in the real world, its digital representation, and their connecting information, which is continuously updated in realtime. The characteristics of this information are also various and cover all kinds of data sources, e.g., process data, master data, metadata, or ERP data. Algorithms and applications, in general, may help to enrich this data with information.

Digital twins are part of the supply chain throughout the entire lifecycle of products, machines, processes, or services and offer different values and advantages at each stage. Already applied in the design phase, the digital twin can handle complex product requirements or fast cycles of development and test different designs with specific simulations to make physical prototyping more and more redundant. This results in time, resources, and cost savings in the development of new products. Simulating functionalities and behavior concerning every relevant aspect lowers the degree of uncertainty. Since all functionalities can be simulated, commissioning is more comfortable, and processes are error-free.

Moreover, a digital twin offers the possibility of monitoring and reducing risks, which may lead, for example, to a rise in the overall availability of a machine or a process line. Robust prognoses regarding the properties, the quality, and the behavior of products and machines can be identified, and replacement planning and investigations of upcycling potentials. As the digital twin concept leads to a holistic view of products, machines, processes, and the entire supply chain in realtime, the communication between suppliers, producers, and customers becomes faster and more comfortable.

The role of digital twins in the Learning Steel Plant

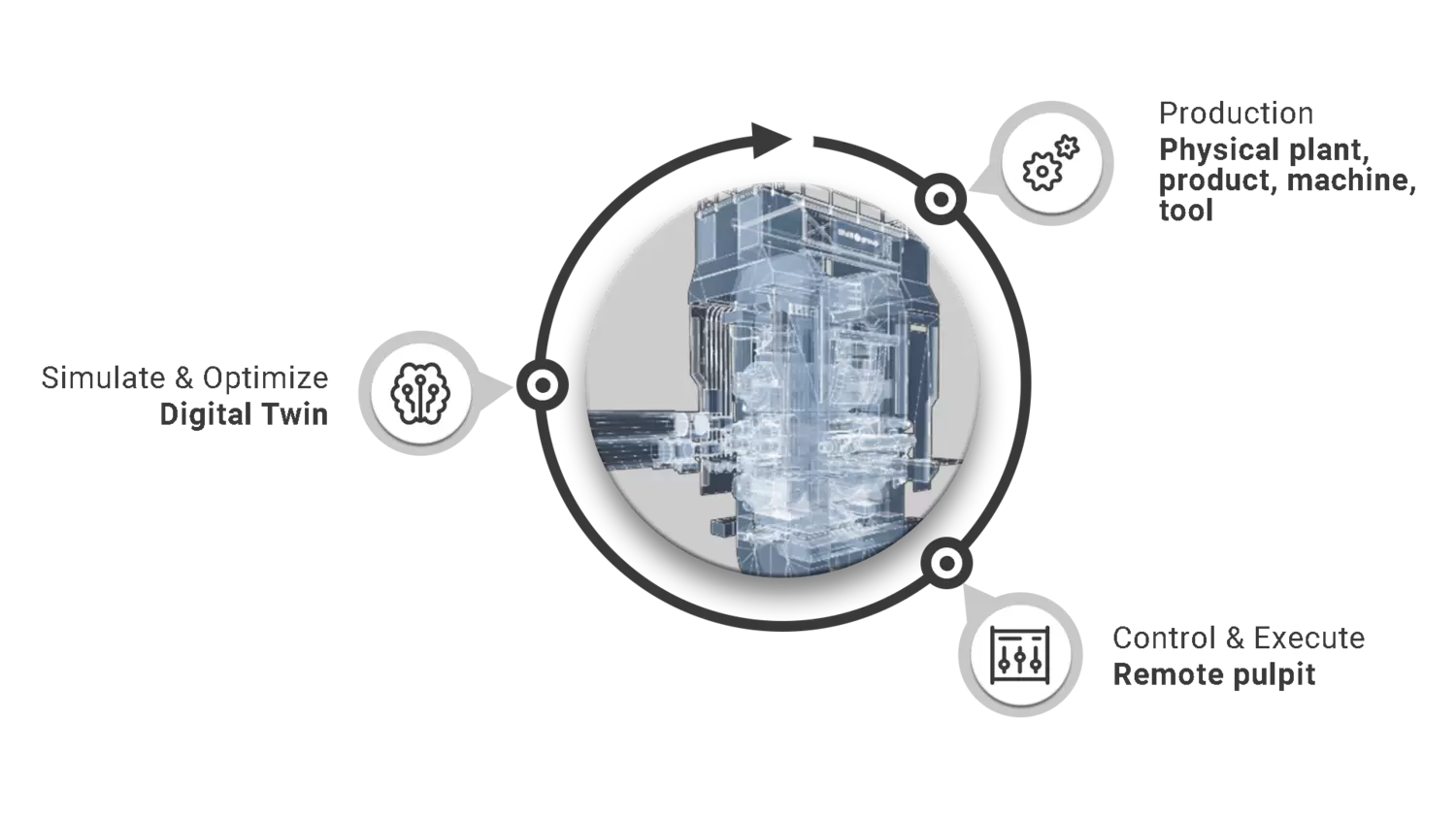

In the vision of the Learning Steel Plant, the concept of digital twins plays a crucial role. Covering all information on machines, products, and processes, the digital twin is an efficient tool to create a deeper understanding and knowledge utilizing artificial intelligence, machine learning, and even human studies on past and future scenarios.

The main advantages that the SMS group and SMS digital offer with the digital twin are:

- Monitoring: All relevant plant, machine, or product-related information is gathered and visualized in a lean and easily understandable way. It is even possible to display realtime process data in a 3D replication of the real object where they appear.

- Simulation: Testing new products or production routines on the digital twin is less expensive and faster than running real campaigns in test mode. Process optimization and finetuning can be carried out while avoiding risks and production losses.

- Optimization: By providing the design and behavior of a whole plant with all its processes, material flows, and working routines, it is possible to recognize bottlenecks in material or crane logistics utilizing production simulation. Changing parameters, machines, and locations lead to an optimized plant design with optimum production conditions.

- Prediction: With machine learning and artificial intelligence, critical aspects of processes, plant condition, availability, and product quality can be predicted and adjusted to current circumstances.

- Domain know-how: Being a system supplier for the metals industry, SMS group can provide mechanics, electrics and automation, serviced, and digitalization from one hand. All those data, plans, layouts, and information can easily be broad together in a digital twin for SMS equipment. Integrating third-party equipment, of course is possible, too.

- Education: The ideal replication of the real machines and processes in the virtual world combined with a 3D visualization created directly out of the construction plans makes it easier and faster for new operators or service staff to learn everything about it – from simple maintenance tasks to complex process control.

The digital twin application layer

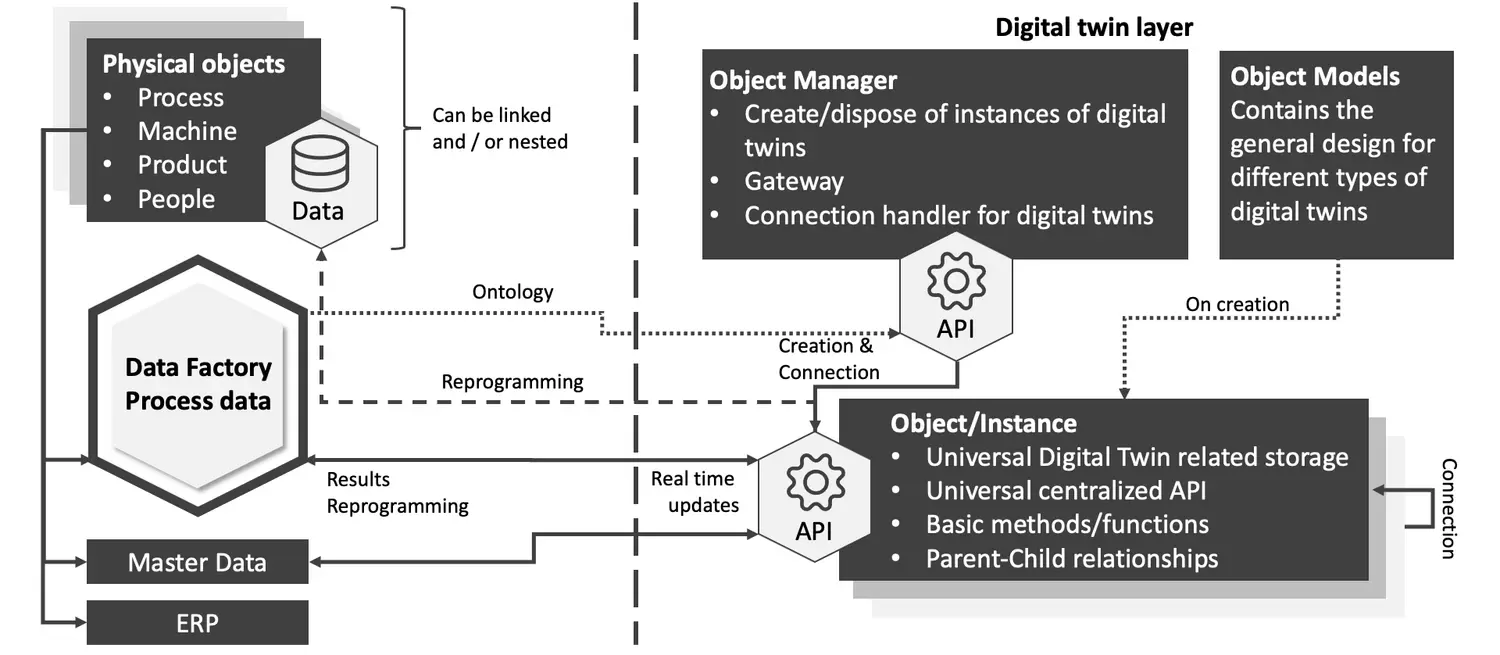

To provide all these benefits mentioned above, the digital twin needs to fulfill certain functionalities and underlying software architecture. For almost every topic, a software solution exists, e.g., for a simple calculation of the wall temperature in a furnace or for the complex mechanisms needed to control it. Another example is the integration test for the Level 1 automation that is executed to simulate processes and production before the automation system is deployed in the real environment. This test environment also serves for the education and training of the operators. The potential that is offered by bundling these isolated and separated solutions finds its way in the digital twin application:

The digital twin application mainly serves as a centralized and unified interface. This means that all SMS group applications, SMS digital, and its customers and third-party apps can be connected to the twin. The idea is to supply all the knowledge and results bundled in existing applications to the digital twin to enrich its data. This way, the digital twin keeps growing and becomes more reliable with the amount of applications connected to it. The fact that a digital twin instance is bound to a unique real object further simplifies the identification in the virtual world for external applications that tend to use their ID to track objects.

Building a digital twin requires a high degree of connectivity between data, applications, twins of other entities, and objects in the real world. Connectivity also requires homogenization of data and protocols, thus a general form to store and transmit data or digital contents. These two topics are the main challenges and also form the basic modules of the digital twin independent of the use case. Another issue is the digital twin application's modular design that allows the mapping of nested and linked structures. For example, the digital twin of the process of casting needs the digital twin of the casting machine, which also contains the digital twins of its parts. These sub twins must be linked together. Furthermore, a digital twin of the products that occur in the process must also be taken into account: Out of different melts that are given into the tundish, a strand is created that is finally cut and organized in slabs or blocks.

Overall the digital twin application with its connectivity, modularity, and data orchestration offers a suitable platform for every application to run on. Offering the past, the current, and even future data homogeneously, it is easy to apply machine learning and artificial intelligence, run simulations and make predictions with an impact on production and availability.

A digital twin is not merely a product but an individual solution that is completely tailored to the customer's requirements. A complete plant can be represented as a digital twin, but also process models or individual tools. Therefore, the digital twin is not designed as a \"one fits all \"solution for a concrete problem but contains different functionalities that can be adapted to various issues. Additional applications can be bundled via an interface and seamlessly access information from other applications.

It is not always necessary to take material samples and thus consume valuable resources, but the digital twin data can be used for virtual testing purposes. The digital twin is an excellent example of the digital transformation that enables the physical and digital worlds to be networked with each other ever more realistically and to make the manufacturing industry ever more efficient and sustainable.

More information

Find more information about digital twins and some use cases on our website.