Concast – pioneering partner along the caster lifecycle

As a leading partner for billet, beam blank, blooms, and vertical continuous casters, SMS Concast helps steelmakers get the most out of their equipment throughout its entire life cycle – from designing a new plant or casting line to optimizing operations, maintenance, consumables, spare parts, and repairs, all the way through to innovative modernizations.

SMS Concast will stay at your side all along the life of your continuous casting machine for billets, beam blanks, or blooms. From building the plant, and during its operations and maintenance, through to upgrades and modernizations, we offer a wide range of training and service programs, as well as OEM spare parts and consumables.

Are you planning a new casting machine or do you want to introduce new steel grades, replace old equipment, or upgrade existing systems? SMS Concast offers exceptional stand-alone products, be they technological or digital. With its vast experience and innovative ideas, SMS Concast is your leading partner for long-product casting optimization.

-

Billet caster

Custom solutions for all steel grades

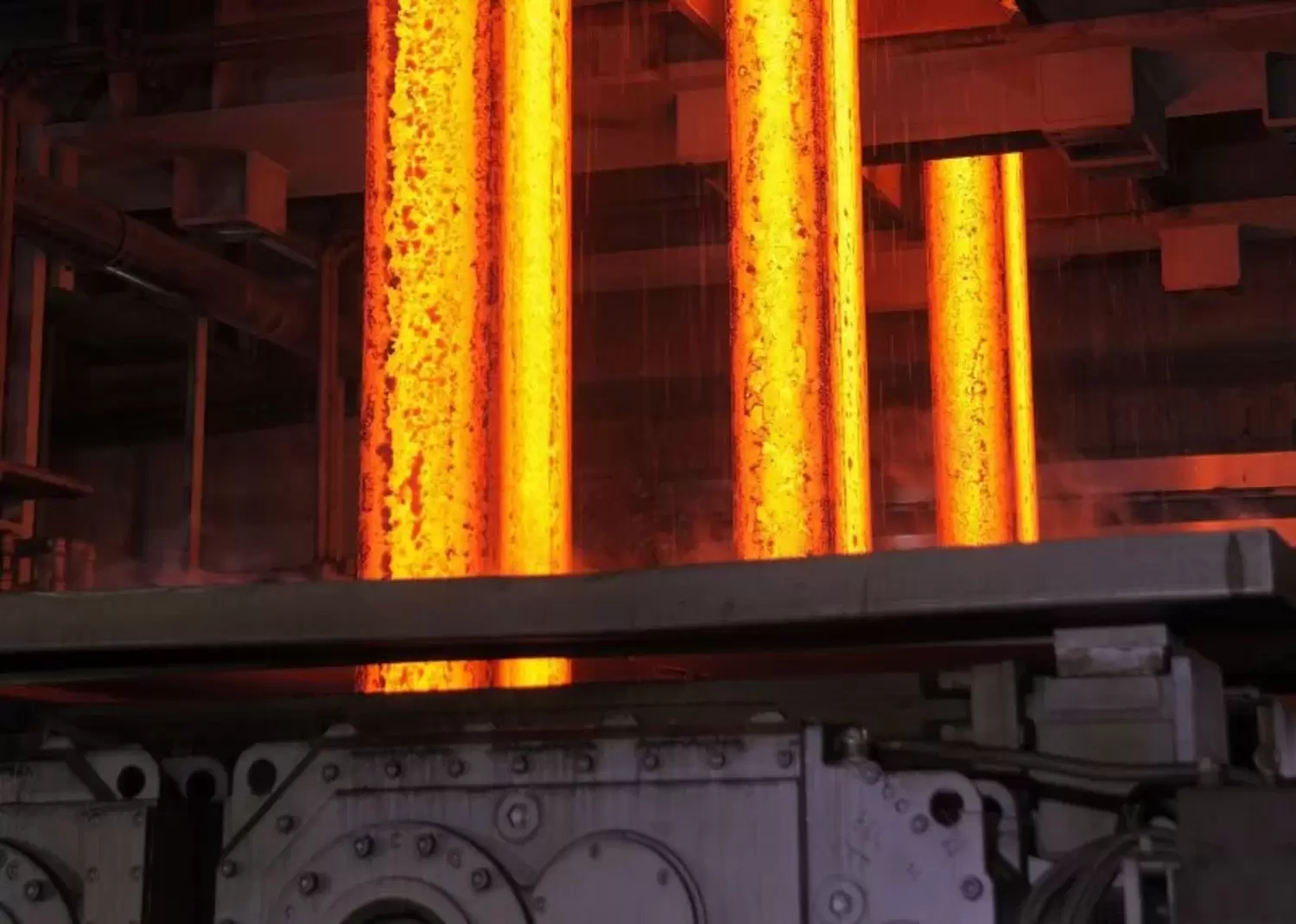

Main dataSMS Concast designs highly versatile billet casters, providing greater flexibility in production so that plant operators can react to changing market demands extremely quickly. Together with the development of secondary metallurgy, SMS Concast has sparked a revolution in its advancement of near-net-shape casting technology and paved the way for the further development of many plants in terms of the quality and quantity of their products.

Continuous casting for billets covers both small and medium round sections as well as same-sized rectangular and square sections, the typical size range of billets is 85–200 mm.

![]()

-

Bloom caster

High-end solutions for the best quality and large products

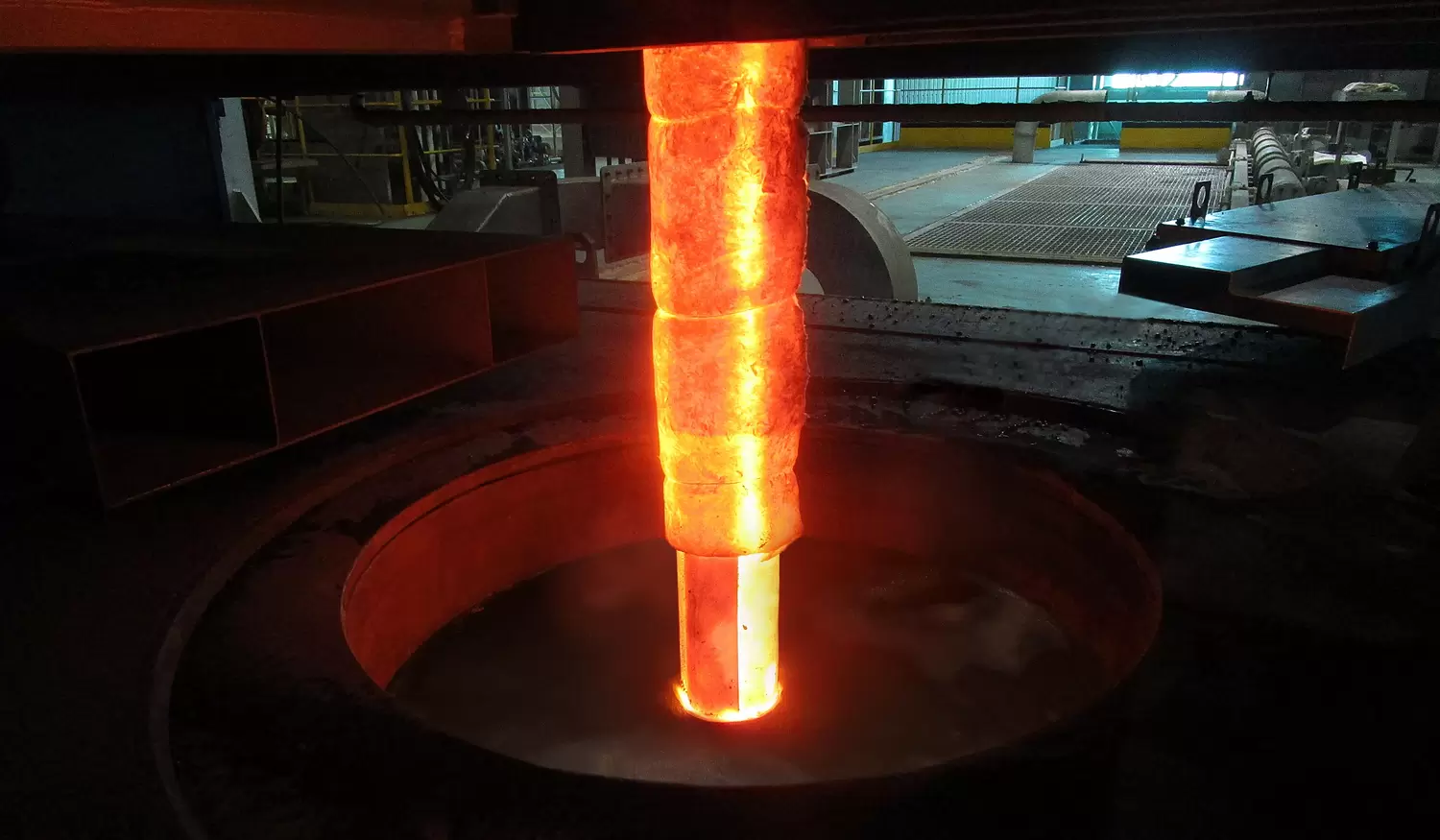

Main dataBloom sections are required in cases where final steel products of the highest purity and flawless internal quality are to be produced for high-end applications. The same applies to particularly large end products.

In order to achieve the required purity and internal quality, SMS Concast continuous bloom casters have some striking features, such as the tundish heating systems, integrated molds (including INVEX® mold technology), an electromagnetic stirrer system (CONSTIR), innovative strand support design, including dynamic mechanical soft reduction (DMSR), and controlled surface quenching. DMSR is necessity in order to achieve a sound bloom center and minimized center segregation. In addition to the mechanical components, SMS Concast also supplies the metallurgical models, such as the COOL solidification model.

Blooms can be as well cast on vertical casting machines and may very well replace ingot casting machines.

![]()

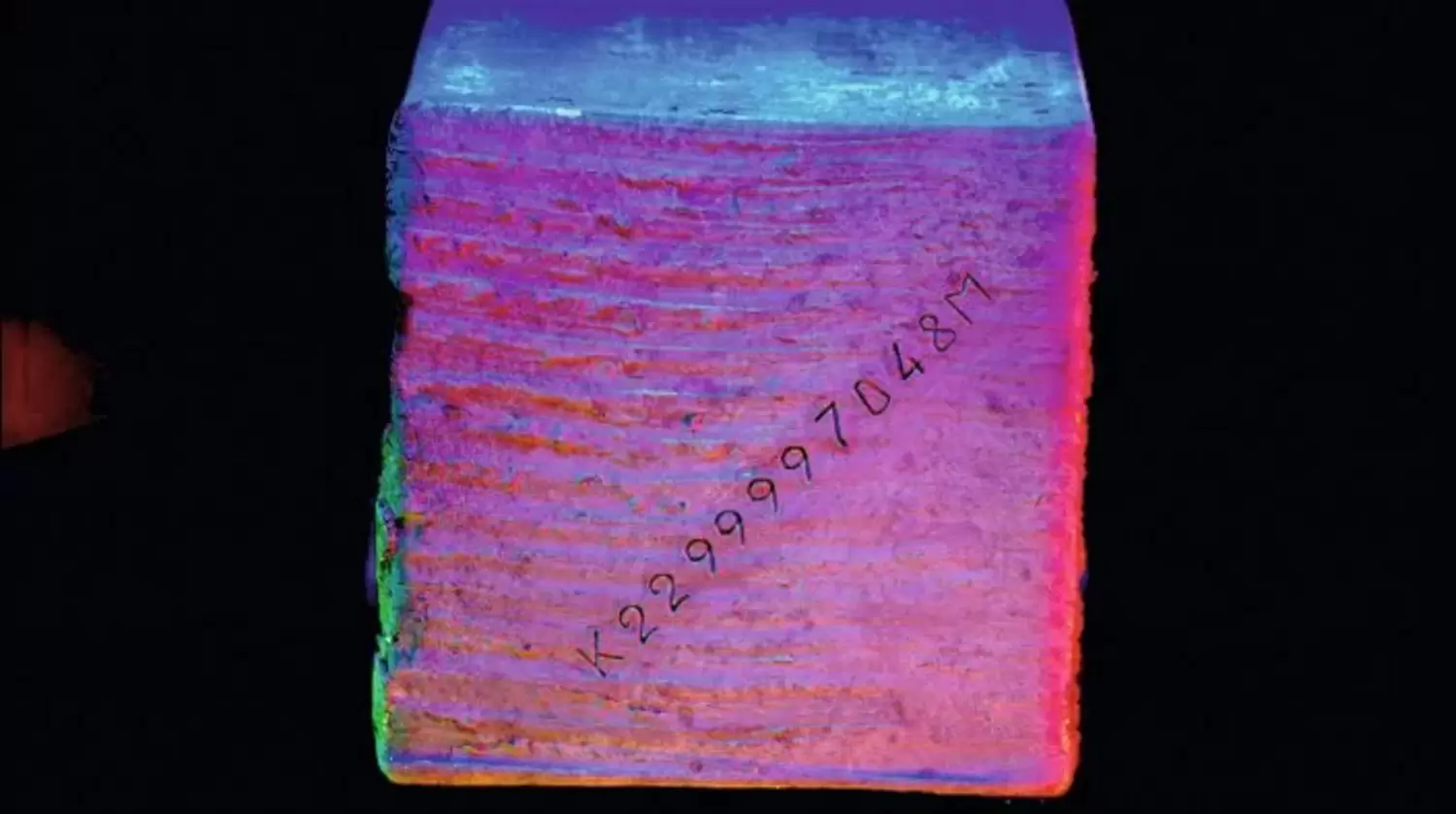

Cast blooms -

Beam blank caster

Optimal solutions from the market leader

Main dataBeam blanks are near-net-shape products used to feed medium and heavy section mills. This state-of-the-art casting technology was invented by SMS Concast, which is the market leader in this specialist field.

Where beneficial, SMS Concast can equip the casters with special strand-reheating systems to control the beam-blank tip temperature before entry to the straightening zone. This is particularly important when micro-alloy steel grades are cast in large beam blanks, both to optimize the metallurgical properties and avoid transverse cracks. Also the SMS Concast ExpertShape mold tubes have a very positive impact to reduce web crack formation.

An important aspect is that SMS group can offer the complete processing chain for the production of beam blanks from one source: SMS Concast provides the caster, whereas the remaining parts of the process come from the global market leader SMS group, such as the EAF melt shop and secondary metallurgy upstream and downstream the required medium or heavy section rolling mill.

![]()

Beam blanks -

Vertical caster

High-end solutions for special steels and semi-continuous vertical caster

Vertical casting is an excellent alternative to a curved bloom caster of ingot casting for higher production, which ranges up to 1 million t/year. It also aims to achieve high product quality. Continuous vertical casting offers various advantages, such as avoiding any bending and straightening of the strand and creating excellent conditions for the better separation of non-metallic inclusions in the mold.

All curved continuous casters require the unbending of the curved strand in a straight horizontal direction. Depending on the section size, caster radius, casting speed, and steel grade, this unbending process leads to stresses and high levels of rates of strain within the just-solidified strand shell. In case of critical steel grades, this unbending and straightening process results in cracks either on the surface of the strand or at the solidification interface.

These problems can be overcome by pure vertical casting, since in the casting process any stresses and strains due to unbending is avoided, or by using a semi-continuous vertical caster to implement ingot casting.

![]()

Vertical casting -

VERSCON

Semi-continuous casting

The semi-continuous casting process is already a standard application for non-ferrous metals such as aluminum and copper. Still, the adaption to steel casting adds increased complexity due to its slower solidification rate.

The driving idea behind the VERSCON semi-continuous casting process developed by SMS group, is the requirement to cast one or two ladles on one or more strands into long blooms. The huge bloom length ensures a higher yield, whilst the semi-continuous casting process using a conventional mold and oscillation table guarantees a bloom surface comparable to that achieved by continuous casting. Once the strand has reached its final length, casting is stopped, and the strand is held in position until final solidification is achieved.

The VERSCON semi-continuous casting process combines the following advantages: utilization of small-scale production units (low CAPEX), improved yield compared to ingot casting, better surface quality than ingots, and an internal homogeneity and quality comparable to that of continuous casting.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

CONDRIVE

Online oscillation control simplified

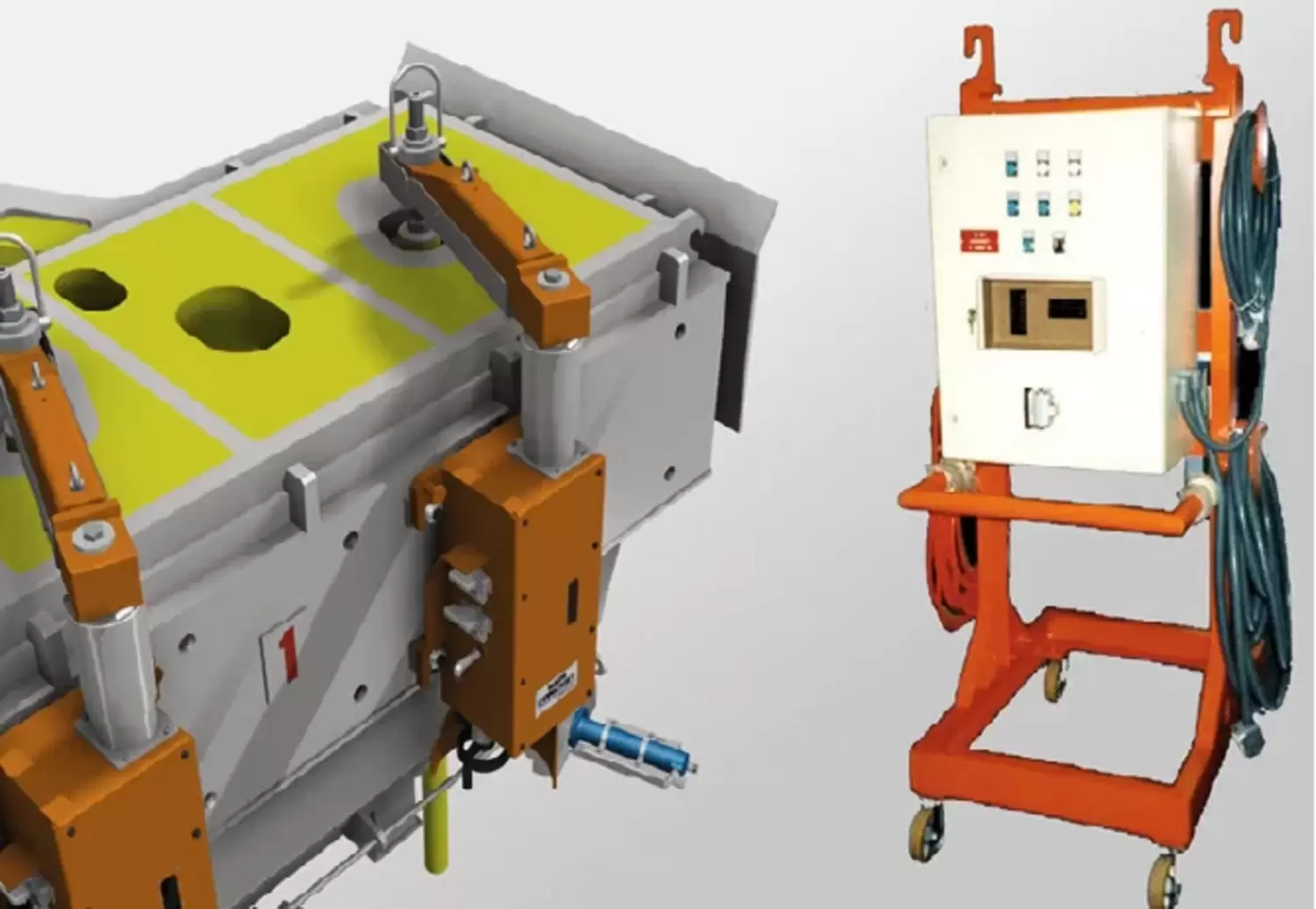

CONDRIVE is a new electric oscillation drive that delivers the functionality of hydraulic servos at a much lower price. Its innovative torque drive enables online adjustment of the amplitude, frequency, and oscillation profile independently.

Oscillation parameters are no longer a compromise because each casting section and grade gets its own oscillation parameters, tuned to the best product surface. Online stroke adjustment is now both affordable and easy to use.

![]()

CONDRIVE -

CONGAUGELB6755

Steel & powder level measuring

One compact unit reads liquid steel and powder levels simultaneously. Getting the steel and powder levels right in a continuous caster supports smooth casting and higher product quality. Until now, steel level sensors have ignored powder thickness. Establishing this vital parameter required an additional device, adding costs and complexity. SMS Concast’s CONGAUGELB6755 is a new, multitasking radiometric sensor that determines both the steel level and the thickness of the powder layer in the mold tube. Product quality goes up, and stoppages go down.

![]()

CONGAUGE -

CONSTIR-EMS & CONSTIR ReNEW

Robust, long-life stirrers customized for your caster

Electromagnetic stirrers (EMS) improve steel quality and support a smooth and stable production process. Durable and cost-effective, SMS Concast’s stirrers are the industry benchmark, with more than a thousand units installed worldwide.

Almost any SMS Concast EMS can benefit from a CONSTIR ReNEW overhaul and return to service either with its original specifications or new customized needs.

![]()

CONSTIR -

CONFLOW

Assuring a stable steel floe for reliable casting

Especially for special steelmakers, consistency is vital to profitability. Precise stopper control in the tundish is where consistency begins. CONFLOW Tundish Stopper Controls assure stable and accurate steel levels in the mold, which are key to product quality. With over 2,000 units installed worldwide, SMS Concast’s CONFLOW is the industry standard for tundish stopper controls. It’s engineered for ease of use and a long, trouble-free service life.

![]()

CONFLOW -

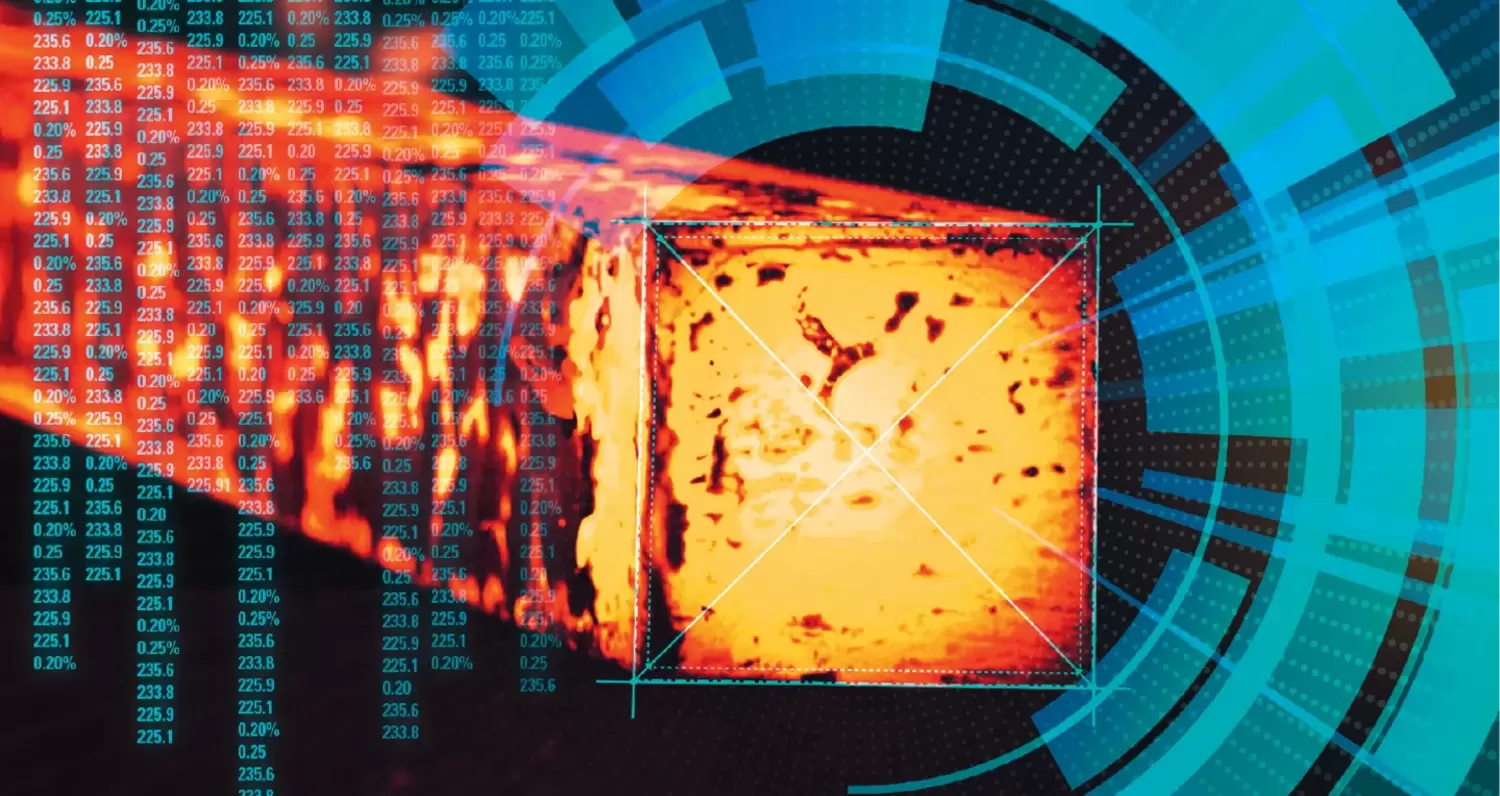

COOL

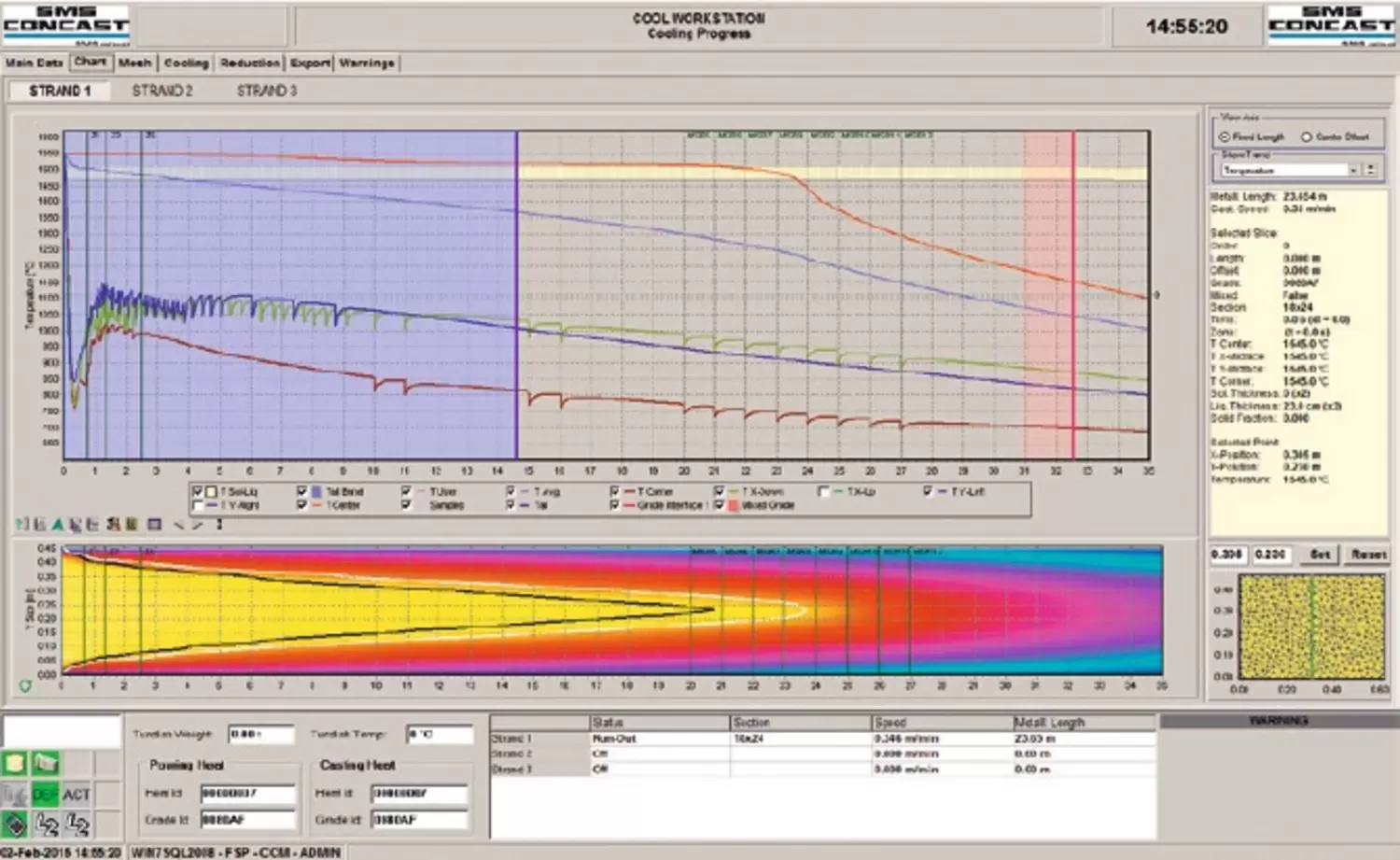

The real-time solidification model. Fine-tune your continuous caster.

SMS Concast’s real-time solidification simulator, COOL, has proven itself in many plants around the world. It enables you to control and fine-tune your caster with an accurate, detailed temperature profile of the strand as it solidifies – online, and now, also offline. Combining SMS Concast’s vast metallurgical and process automation know-how, COOL lets you optimize caster inputs for maximum product quality and process stability.

![]()

Solidification model -

CONREAD optical product recognition

Track your products seamlessly, from caster to customer

Product tracking is part of modern steel production. Steelmakers supplying the machine tool or automotive industries, among others, face stringent quality requirements. Delivery mix-ups simply cannot be tolerated and their consequences for the steelmaker can be costly. CONREAD tracks every product you make, assuring flawless deliveries every time.

![]()

CONREAD -

CONSHAPE online cross-section checker

Online, on-the-fly shape detection for enhanced quality and productivity

Productivity and quality are every steelmaker’s goal. SMS Concast is dedicated to providing steelmakers with solutions to achieve both. Using our proven high-resolution imaging system, our CONSHAPE cross-section checker acquires an image of the precise shape of every billet or bloom and checks it for quality parameters like rhomboidity and bulging.

It enables steelmakers to make rapid, on-the-fly adjustments to improve quality and yield.

![]()

CONSHAPE -

Continuous casting mold tube

Tapered precisely to your specifications

The right continuous casting mold tube will greatly contribute to the billets’ quality in terms of surface, internal structure, and shape. We have the knowledge, experience, and expertise to create the right continuous casting mold tube every time. Your continuous casting mold tube maintenance and care will increase its lifespan and enhance overall quality and productivity. Each copper mold tube is a financially viable option that will last for many heats with our range of aftercare and refurbishment services.

SMS Concast has been designing molds since it introduced continuous casting to the steel industry in 1954. In 1991, our CONVEX Technology® mold tubes boosted caster throughput by up to 30 % over conventional molds. For many years now, SMS Concast has not only designed but also manufactured mold tubes tailored to your specific needs. We don’t outsource these critical parts, we produce them in-house.

The mold assembly being the heart of every continuous casting machine, SMS Concast offers advanced integrated mold solutions based on the caster requirements and optimized for:

- Higher casting speeds

- Optimized metallurgical processes

- Extension of mold service life

- Improved quality (geometry, surface, internal)

- Reduced break-out rate

- Increased yield

SMS Concast is not only at the forefront of mold technology developments, it also manufactures mold tubes itself.

![]()

Casting molds

Services for this plant

Sorry, there are no results for the search term.