西马克集团为钢液的二次精炼提供各种设备方案。这些先进的设备能满足您对最终产品质量的高要求。根据您的具体要求,我们为您量身定制解决方案,以应对冶金、物流和生产率方面的挑战。

-

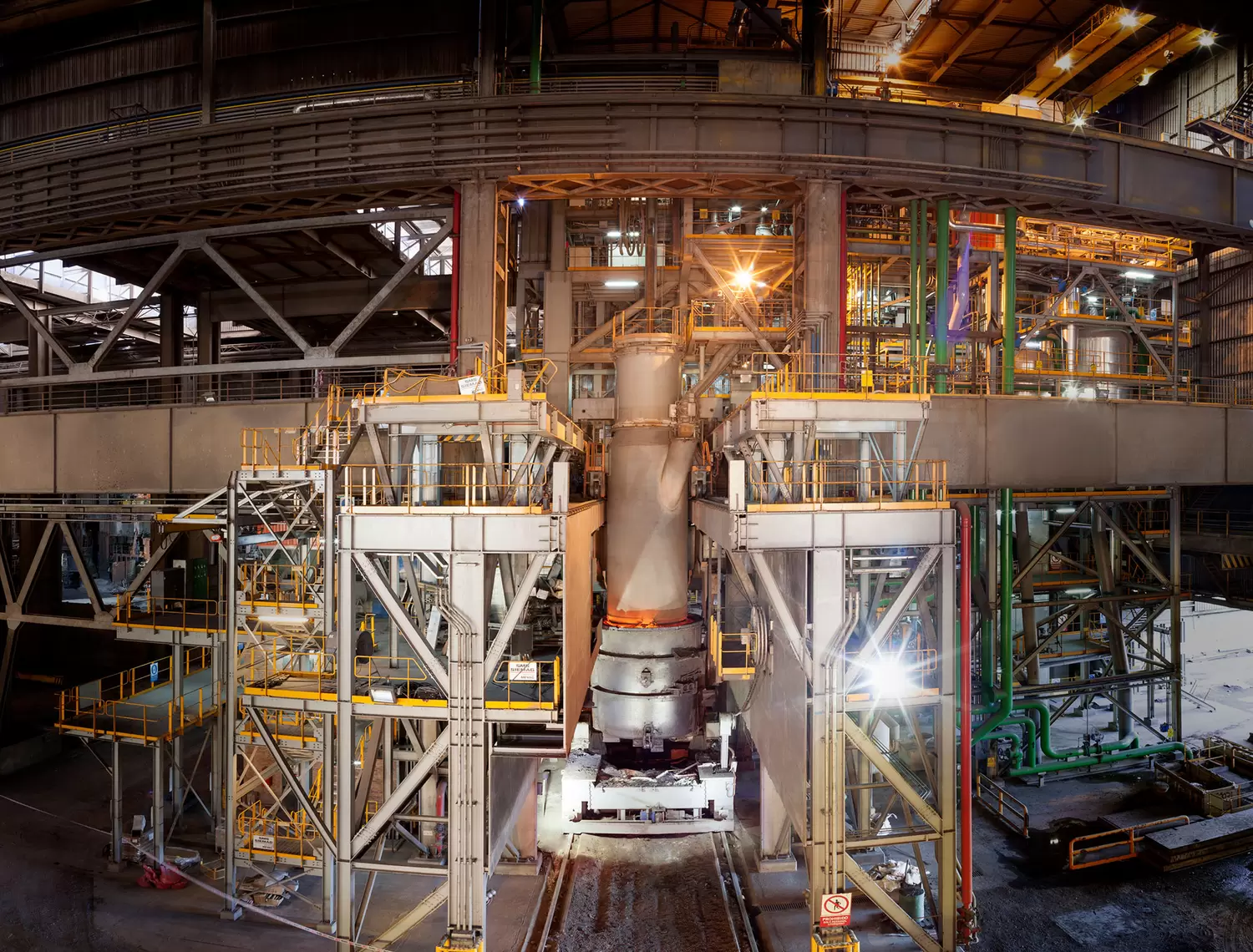

钢包炉技术

优质金属生产解决方案

西马克集团拥有 500 多座新建和改造项目中的钢包炉,是世界领先的钢包炉技术供应商之一。

西马克集团的钢包炉和优化的生产工艺提供了最具成本效益的解决方案,从而以较低的生产成本实现了较高的生产率。西马克集团钢包炉技术的所有组成部分都是以降低钢铁生产成本为目标而开发的。因此投资回报更快。

优点

- 根据工艺和布局进行模块化设计,优化投资成本

- 标准化的部件组合降低了维护成本

- 降低生产成本

- 生产高质量钢材

- 优化工艺流程的二氧化碳排放量

![]()

-

RH炉

真空条件下的二次冶金

西马克集团的 RH 工艺在全球拥有 180 多套设备,处理能力最大可达 400 吨,其特点是脱碳和脱气效果非常好,温度损失相对较低。它特别适用于周期时间较短的熔炼工艺。

RH 工艺不需要特殊的除渣措施、额外的钢包净空或钢包底部的透气砖。快速的炉体更换和高效的钢包运输模式提高了设备的产能,而使用双工位则可进一步提高产能。

RH 工艺具有以下特点:

- 脱碳至最低碳含量

- 快速脱氢

- 合金化精度高,收得率高

- 快速加入大量合金

- 即使添加大量合金,钢包内的钢液也能快速均匀化

- 真空脱碳脱氧处理时间极短

- 温度损失相对较低(取决于批量大小)

![]()

RH 炉 -

真空脱碳

真空条件下的二次冶金

自二十世纪五十年代末以来,西马克集团的 VOD 工艺(真空吹氧脱碳炉)已成功应用于不锈钢、耐酸钢和耐热钢的生产和精炼。迄今为止,已有 100 多套处理规模达 200 吨的设备采用了这一工艺。通过在减压状态下吹氧脱碳,铬的氧化作用大大降低,从而以经济的方式达到特别低的碳含量。还原剂的消耗也大大降低。

VOD 设备可紧接在冶炼装置之后用于两步法生产线(电弧炉 - 脱渣 - (LF) - VOD),或与 AOD 转炉一起用于三步法生产线(电弧炉 - AOD - (脱渣) - VOD)。特别是在生产含碳量最低的不锈钢(如超铁素体钢)时,VOD 工艺是无可替代的。

我们的 VOD 设备是根据生产计划的具体要求、钢厂的时间安排以及客户的个性化工艺而设计的。每套 VOD 设备还可用作 VD 或 VD-OB 设备。

![]()

VOD 炉

为您的工厂提供的服务

抱歉,搜尋詞彙沒有結果。