We are taking up the challenges of digital transformation and Industry 4.0 and develop innovative solutions that boost your business. Benefiting from state-of-the-art development methods, our software solutions for predictive asset health, product quality, production planning and energy management contribute in actively saving money, increase profitability and conserve resources.

Use our digital technologies to turn data into information and information into value.

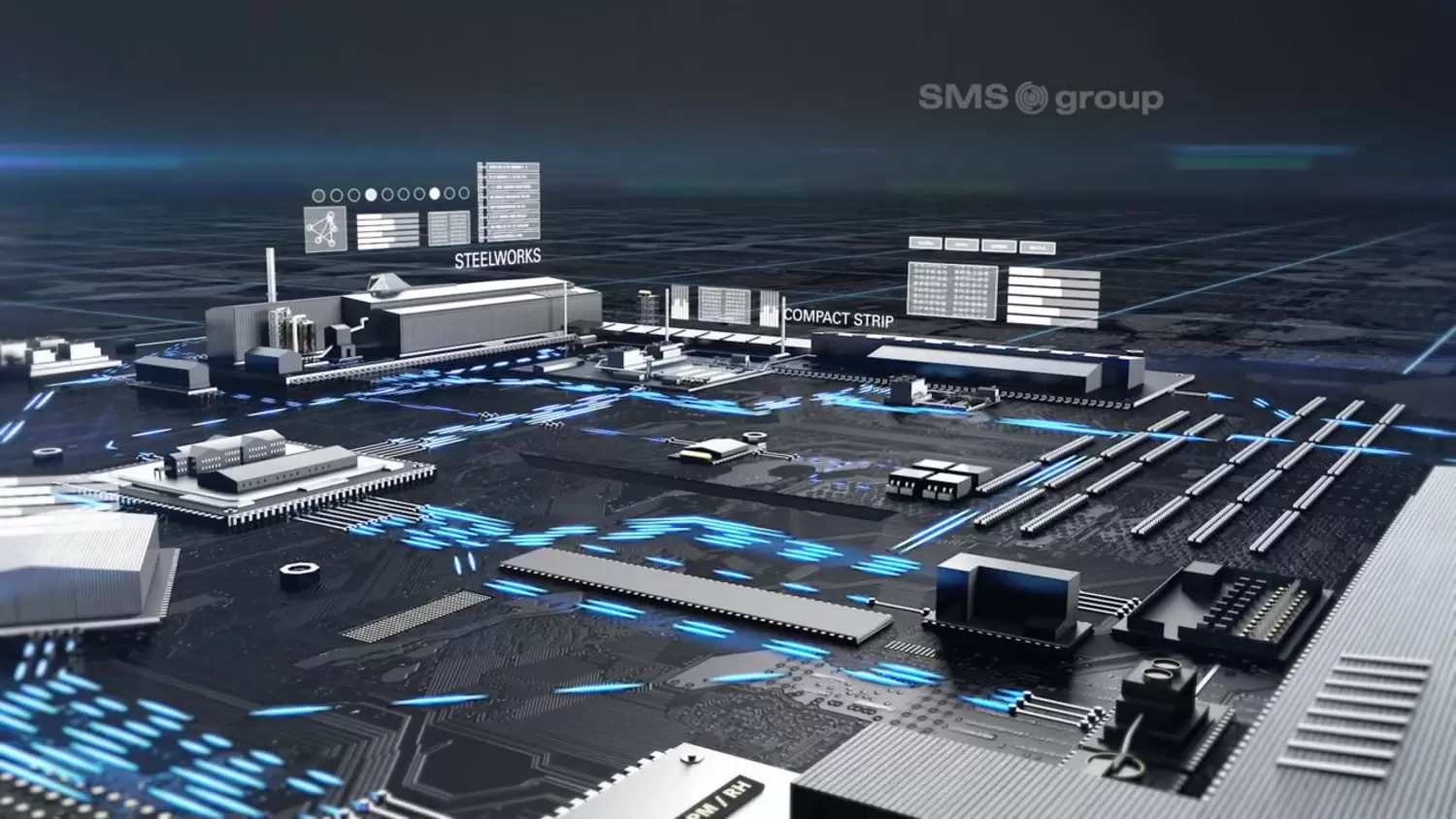

The digital future has already begun.

Service categories

The first learning steel plant

Our vision comes true

Big River Steel produces pipe grades for pipelines, silicon steels for electrical steel and AHSS grades for the automotive industry on SMS group equipment. As systems supplier for the steel mill complex, SMS group supplied all the equipment, process know-how and automation technology and supported BRS during commissioning.

From the combination with SMS digital's innovative solutions for data infrastructure, digital products and machine learning resulted in the world's first learning steel mill.

Services for digitalization

DataXpert

DataXpert is a complete platform for developing and managing condition monitoring and expert systems that provide real-time recommendations and notifications.

Asset Optimization Platform

Genius Condition Monitoring

The Genius Condition Monitoring is a modular online screening system for permanent monitoring of steel plants that records the process data of your plant

Quality Execution System

The Quality Execution System captures all quality data and enables the systematic introduction of an automatic coil release system for all production lines

Viridis Demand

Viridis Demand enables accurate energy demand forecasting in the steel and metal industry. It helps to avoid resource shortages, overloads and penalties.

Digital twin

Digital Twins are part of the supply chain throughout the entire lifecycle of products, machines, processes, or services and offer different value and advantages at each stage. Already applied in the design phase, the Digital Twin can handle complex product requirements or fast cycles of development and test different designs with specific simulation.

Integrated Maintenance Management System

IMMS is the plant specifice Maintenance Management System from SMS group for all maintenance and shutdown planning

Manufacturing execution suite

The MES 4.0 manufacturing execution suite is the holistic, modular solution for planning and controlling the whole metallurgical process chain and all production facilities as part of upgrades, expansions, or new integrated plants.