For a project with Aperam Stainless Belgium, SMS group uses latest Virtual Reality (VR) technology. VR helps to continually check the plant concept and engineering details as well as to facilitate communication within the project team and with the customer.

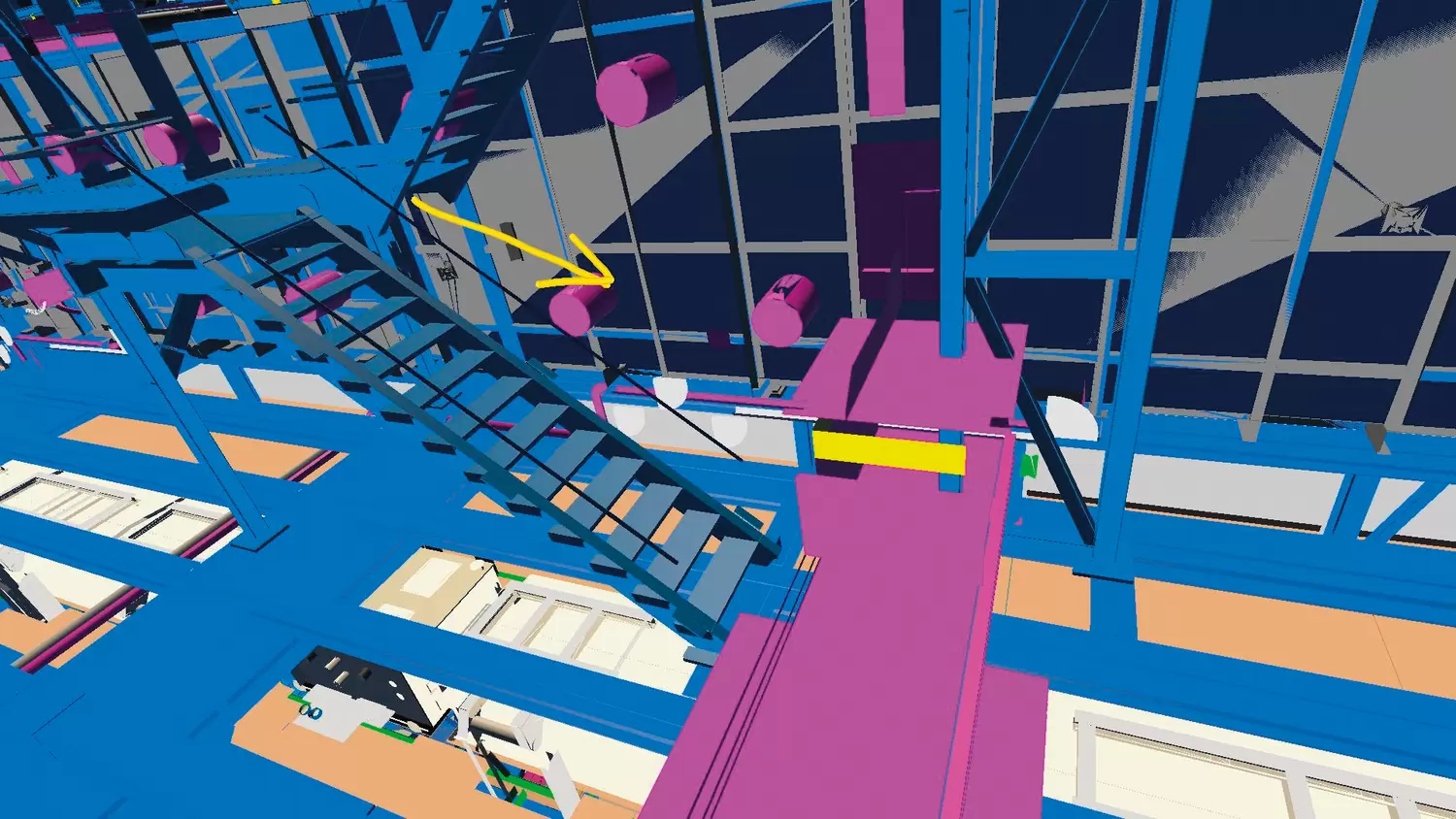

In 2018, Aperam Stainless Belgium has contracted SMS group to supply an annealing and pickling line for stainless steel cold strip for its Genk location. The conditions at the customer’s site require a very complex layout configuration with a plant length of almost 400 meters. The technically demanding layout extends over several floors and includes besides a horizontal annealing furnace and a multistage pickling section, many other mechanical components.

Therefore, modern VR technology (Virtual Reality) was used for layout and plant planning allowing the local conditions to be viewed from a full 360-degree perspective. This innovative use of virtual reality offered Aperam numerous advantages. Among others, the customer had the opportunity to directly experience the machines and systems in their original size in the virtual room.

When preparing a 3D plant layout, potential collisions of components or neighboring machines could rapidly be revealed and eliminated at an early stage. Based on 3D virtual plant tours it was possible to continually check and improve the suitability of the concept and thus to facilitate communication within the project team. Detailed planning and project work on issues as risk assessment, workplace safety and escape route planning for the operating staff brought clearer and safer results and could be finished much earlier. Improvements could also be achieved for pipework planning. Many further advantages will arise in the course of project handling since the VR technology helps to considerably enhance the understanding of the current status of design activities and modification steps. In the erection phase. The model is also used as a basis in regular meetings and video conferencing to coordinate interfaces and communicate on technical issues jointly with Aperam.

Improvements identified

In the engineering phase and the early implementation phase, the use of VR led to a number of improvements in design. Discussions on equipment planning with participants from different technical departments were held via VR, so to speak “on site”, providing distinctly more transparency in the planning process. This method also reduced the risk of misinterpretations, prevented misunderstandings in communication and optimized internal procedures.

Virtual Reality is not merely 3D. In the first place, Virtual Reality is a tool to avoid mistakes or a technology for preventing errors with great potential at many different levels.

Efficient coordination

As early as in the sales phase, 3D plant and layout planning provide seamless access to the project model for all persons involved. This “knowing where” ensures the precise and efficient coordination of all participating departments. Also, layout planning in 3D minimizes sources of error and optimizes pipework and cable route planning in addition to realistic collision detection. Ideas and concepts can thus be visualized in the sales phase already, and the customer has the opportunity in the virtual room to move along his plant and view the equipment configuration in original size.