Flexibility and productivity in cold rolling of aluminum

SMS group offers single-stand cold rolling mills for a broad spectrum of aluminum alloys and thin strip and multi-stand tandem cold mills as the solution for a large production capacity. We completed our portfolio of cold rolling mills by the EDT rolling mill, especially designed for rolling and tempering of automotive grades.

EDT rolling

Customized surface properties for automotive sheets

There are extremely high demands on material for exposed car panels. Here, automotive manufacturers insist on excellent formability during pressing and a perfect surface appearance after painting. EDT rolling transfers this exact finish onto the strip during the final rolling pass.

-

Single-stand cold rolling mill (CRM)

Solutions from the market leader for a wide range of aluminum grades and thin strip

Main dataproducts up to an annual production capacity of up to 200,000 tons. There is nothing to beat the CRM when it comes to hard grades. This mill type rolls a material range from AA1xxx up to AA8xxx series. To suit your specific requirements, you can choose between CVC® plus 4-high or 6-high versions.

![]()

Layout of single-stand cold rolling mill for aluminum -

Combined reduction and EDT rolling mill

Flexible designs for special applications

There is an ever-growing demand from the automotive industry for aluminum. Highly formable 5xxx-series alloys are mainly used for inner car body parts, whereas 6xxx-series alloys are favored for exposed outer parts. To ensure you meet car manufacturers' requirements, we developed our innovative combined reduction and EDT rolling mill. It's available in single or twin-stand versions.

One great advantage is that Inner car body parts and exposed parts can be processed in the same mill. In EDT mode roughness is transferred onto the strip surface by EDT-machined work rolls during a soft reduction pass using lower rolling forces. The “combo mill” can be flexibly operated either in heavy-force reduction modes or in light-force EDT mode.

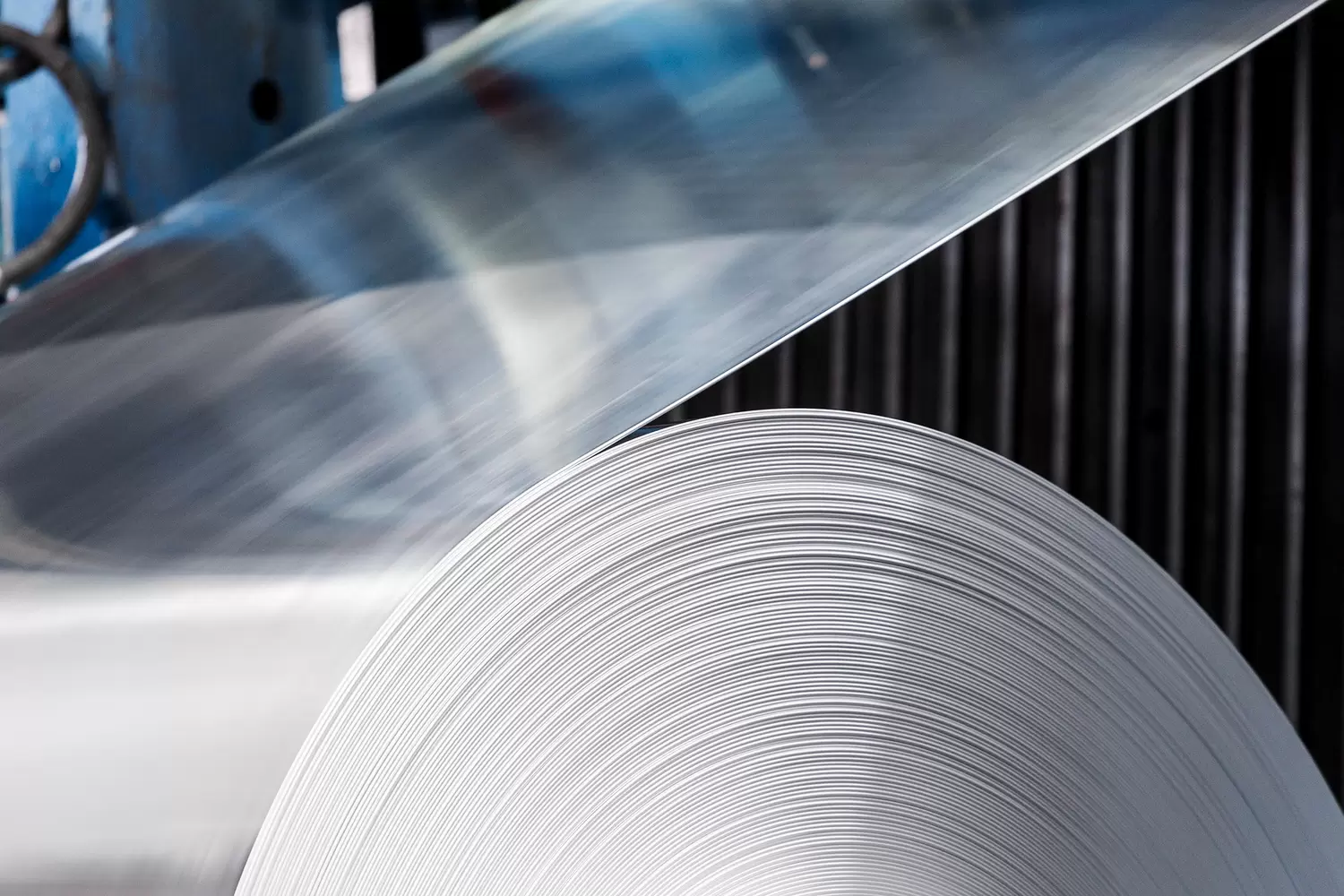

![]()

Aluminum coil -

Tandem cold mill

Solutions for large volumes of high-quality strip

Main dataAA3xxx and AA5xxx-series aluminum grades are typically used for manufacturing beverage cans. This is where tandem cold mills (TCM) from the market leader offer you the most efficient solution. Operating several single-stand mills doesn't make economic sense, especially if you want a production volume of up to 450,000 t/year. Our tandem cold mills for aluminum are available as two stands, three stands or four stands in CVC® plus design.

![]()

Layout tandem cold mill

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

Dry strip system (DS system)

Excellent surface quality

Now available to you is our new-generation DS system. It offers you an ideal, contact-free way to remove rolling emulsion residues from strip. What makes this system so highly efficient is that it needs less compressed air.

Installed in the exit of a cold rolling stand, the DS system simply blows cooling lubricant residues off the strip surface. This effectively prevents stain spots. High productivity is the hallmark of our latest-generation DS systems. That's due to the optimum combination of stationary and movable sealing elements as well as precisely balanced blow-off and extraction areas. One of the core components of the DS system is the wear-proof and contactless sealing of the roll barrel. This is also known as a COANDA nozzle.

![]()

Coil aluminum Benefits

- Sound level below 82 dBA

- 50% lower maintenance costs

- 62% lower energy costs

- 80% fewer rejected coils