EAF technology – solutions for your success

SMS group’s electric arc furnaces (EAF) and optimized processes offer you the most cost-effective solutions for liquid steel production. They are designed to use electricity efficiently, with future-oriented burner and oxygen-injector technology. This gives you high productivity at low production costs. All components of the electric arc furnace technology from SMS group have also been developed with the aim of reducing the presence of operators in dangerous areas. This makes your investment safer and pays off faster.

Using recycled scrap metal, NG or H2-based DRI to manufacture steel products results in lower levels of carbon footprint compared to those made by traditional steelmaking methods.

More than 100 years of development, construction, and commissioning of electric arc furnaces give SMS group a valuable store of experience. With almost 1,400 electric arc furnaces in new construction and revamp projects, SMS group ranks among the world’s leading suppliers of electric arc furnace technology.

The actual portfolio includes a wide range of furnace capacities, from just 4 tons to 290 tons, and thus the upper shell diameter is up to 9.4 m. In terms of electrical features, our EAF family embraces both alternating current (AC) and direct current (DC) EAFs with power ratings up to 300 MVA.

-

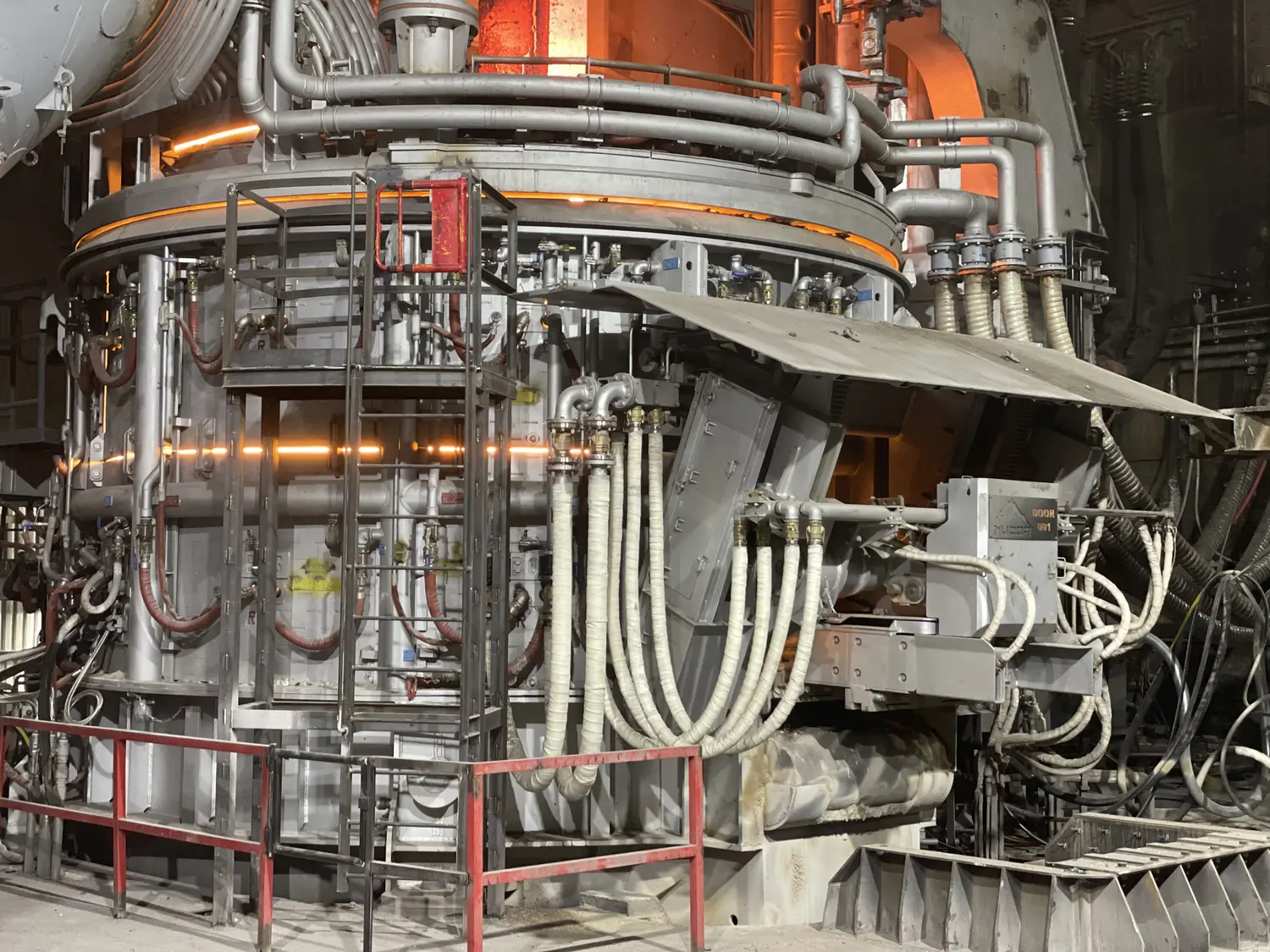

Electric arc furnace

Technological leadership – powerful results

Within the EAF family, the EDGE furnace is the most flexible in terms of layout utilization and raw material feeding. It is ready to accept all mixes of metallics, up to 60% hot metal, and 100% cold or hot DRI, delivering high productivity in a fully automatic environment. Surrounded by modular solutions and powered by the latest generation of electric and hydraulic technologies, it meets all the requirements of a modern and green steel producer.

![]()

-

Allcharge

Continous charging without preheating

ALLCHARGE is our electric arc furnace designed for the continuous charging of scrap without preheating. This technology addresses current and future environmental limits without compromising productivity and safety.

By avoiding scrap preheating, it helps to limit dioxins, VOC, and CO emissions, while the flat bath operation ensures lower NOx emissions and a reduced impact on the power grid. By decoupling the scrap conveyor from off-gas suction, the ALLCHARGE design enables the charging of 100% DRI from the roof.

![]()

-

SHARC (Shaft arc furnace)

The cost-effective melting unit

The SHARC is the most efficient scrap preheating design for electric arc furnaces. Equipped with two vertical preheating shafts (conventional systems use only one asymmetric shaft), the entire furnace cross-section over the height of the two shafts is available for energy transfer. This is made possible by the symmetrical shape of the furnace and the integration of DC high-current technology. The longer retention time of the hot exhaust gases in contact with the scrap results in energy savings of up to 100 kWh/t less than conventional furnaces.

![]()

-

CONPRO

The hybrid furnace

SMS group has developed a new primary smelter called CONPRO in response to rising CO2 emission costs, fluctuating prices of charge materials for the BOF converter process, and anticipated increased scrap availability.

CONPRO integrates BOF converter and electric arc furnace technologies to provide an efficient and flexible energy source combination.

CONPRO can operate like a BOF converter, allowing for a reduction in the use of scrap or other coolants to about 15%. It uses a top lance and side wall lances for oxygen introduction. If molten pig iron is unavailable, or its production is ceased, CONPRO can seamlessly switch to electric arc furnace mode within a single shift, with only minor procedural differences from the BOF mode.

![]()

SMS group email service

Our promise to you: this is not another newsletter!

Use our contact form for questions, inquiries or personal contact.

-

CONDOOR®: High-performance slag door

Enhanced safety and performance at lower operating cost

Each EAF melting cycle involves the formation of new slag and its safe removal. CONDOOR® facilitates all activities carried out in the slag-door area to improve performance, safety, quality, and reduced costs.

The CONDOOR® system for automated cleaning of the sill-breast area enables closed-door operation. It provides reliable access for automatic sampling and managing the temperature gauge. With this highly dependable and productive tool, you will get the highest standards of quality, reduced material and energy consumption, as well as greater yield.

![]()

-

X-Pact® AURA: The digital EAF

Maximum EAF performance with minimum impact on electrical network

The X-Pact® AURA (Advanced Unit Rectifier Assembly) is designed to achieve efficient and stable power controller to feed DC arc furnaces in all power networks configurations, including weak grids. Based on modern IGBT technology, the new design achieves world class performances in terms of current stability, dynamic performances, efficiency, reliability, redundancy and minimum impact on electric network quality. In most cases, no SVC or Statcom is required to fulfill IEEE 519 standards.

![]()

-

X-Pact® Sampler: Manless operation

Safe, reliable, and repeatable operation on the platform

The X-Pact® Sampler is a robotic solution designed for critical operations in process control that require operator presence near the liquid steel bath.

To eliminate risks to personnel and to perform operations with greater reliability and repeatability, dedicated automated areas have been developed. These areas employ commercial 6-axis anthropomorphic robots equipped for the task.

Automatic robot sampling is safer and often faster than human operation, consequently reducing downtime and increasing overall productivity.

![]()

-

SafEBT: The EBT family for cleaning and filling

Safe operation in the EBT (eccentric bottom tapping) area

The SAFEbt addresses a family of solutions for the EBT (eccentric bottom tapping) area, with the explicit goal of removing the operator from that area and decreasing the downtime necessary for EBT sand filling and EBT tapping.

- SafEBT-fill: Automatically fills the EBT hole with sand after every heat

- SafEBT-clean: Keeps the EBT channel clean and increases the success rate of EBT spontaneous opening

- SafEBT-tap: Provides a solution in case the tap hole does not open spontaneously (an alternative to SafEBT-clean)

Services for this plant

Sorry, there are no results for the search term.